Can Turkey develop gas turbine Engines for Fighter Jets and Helicopters ?

TEI TS-1400 Turboshaft Engine to replace American LTECH T800

TEI TS-1400 Turboshaft Engine ( 1500shp ) to power T-625 Utility Helicopter and T-129/T-629 Attack Helicopters by 2021

According to General Manager of TRMOTOR , Turbofan Engine will be ready by 2029 for the first flight with the TF-X

.............................................................................................................................................................

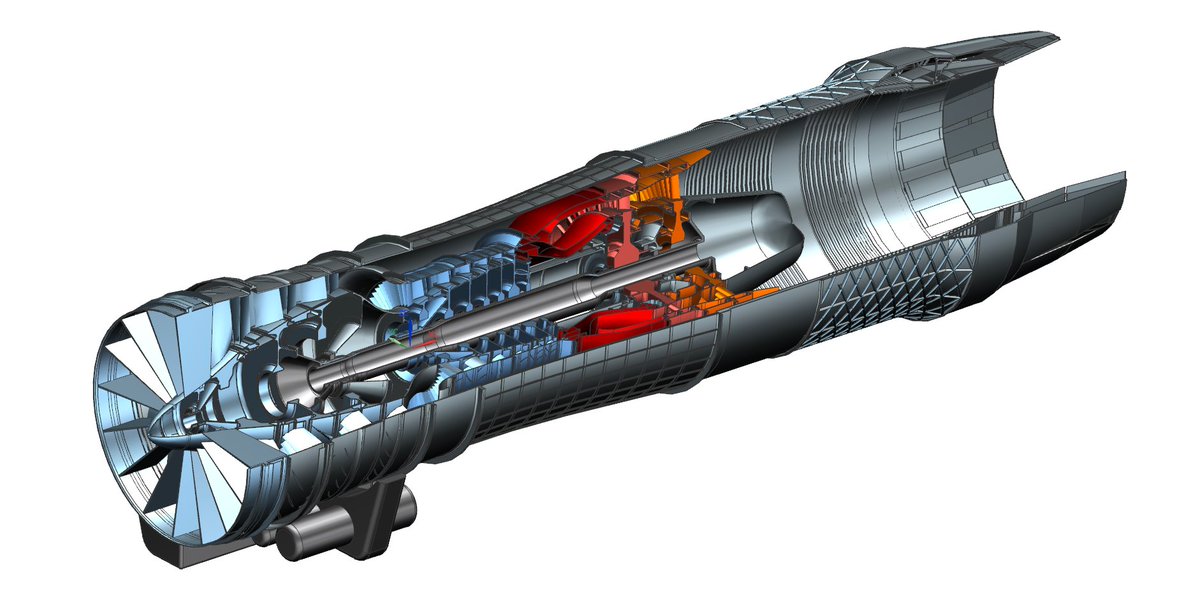

TEI manufactures over 800 components for 40 different Engine programs with its more than three decade experience in part and module manufacturing

-- Rotating Parts (Shaft, Seal, etc.)

-- Modules (Power Turbine Module, Front Bearing Structure Module, etc.)

-- Fabricated Parts (Mixing Duct, Swirl Frame, etc.)

-- Structural Parts (Intermediate Casing, HPT Casing, Combustion Casing, etc.)

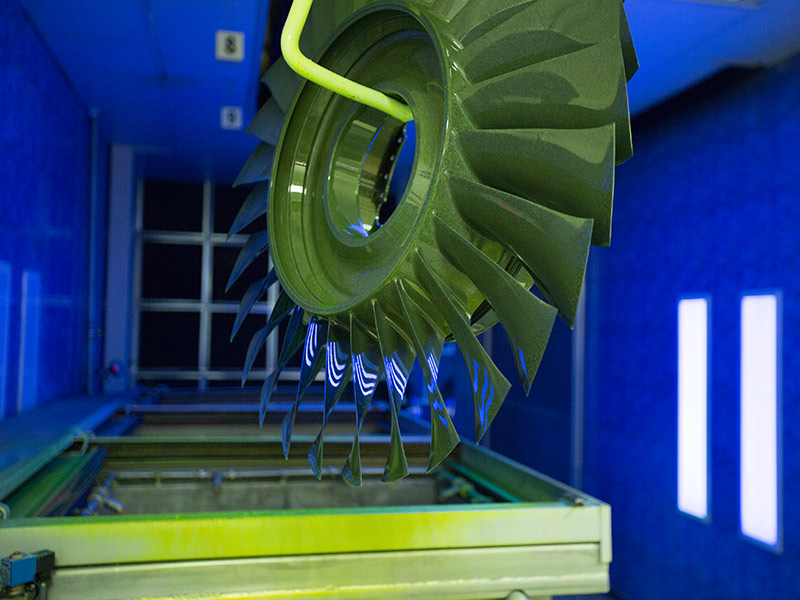

-- Blisk and Spool Manufacturing (Compressor Stg 1 - Stg 5 Blisks, HPC Spool Shaft Stg 10, etc.)

Blisk and Spool Manufacturing Technologies

Blisk and spool manufacturing technologies, recently being used on new generation engines are regarded as state of the art and advanced level applications for aviation industry which are high tech manufacturing methods currently employed in only a few countries around the world and Turkey is one of them

TEI to manufacture Nickel, Aluminium and Titanium alloys and stainless steel for Turbine Engines

Dinç Project: 240t melting capacity aviation quality stainless steel and nickel-based alloys required to be used in aerospace platforms for the defense industry and civil purposes

The Atom Project: This program aims to develop nickel metal powder suitable for layered manufacturing for aerospace applications

The Elektron Project: Development of a titanium layer process using the Electron Beam Melting (EBM) method.

The Ayna Project: Development of new generation Aluminum alloydevelopment

İnci Project: Manufacturing capability domestically for the titanium alloy parts needed in air platforms through precision casting method

Yakut Project: Project aims at acquisition of the Metal Powder Laser Melting (LAM) process as well as the process modeling capability for manufacturing of functional parts that have advanced mechanical features and can operate under challenging conditions such as high pressure and temperature differences in aircraft engines.

The Dilek Project: backed up by the Undersecretariat for Defense Industries, is carried out by TAI and TEI in collaboration with the aim of developing superplastic forming process for titanium alloyswhich are used in both platform and engine applications in aviation industry, and as a result reducing dependence on foreign sources.

Müge Project: The purpose of program is to develop Magnesium Alloy Casting technology