ChineseTiger1986

ELITE MEMBER

- Joined

- Jan 27, 2010

- Messages

- 23,477

- Reaction score

- 12

- Country

- Location

Says who ?... You.. what are your qualifications ??

On whats grounds can you prove it as an AESA ?.. 120 IQ ?

Ever studied about radar engineering...

Answer one correctly I would show you the Indian X-band AESA FCR... along with Transistor chips...

Because i have the direct proof.

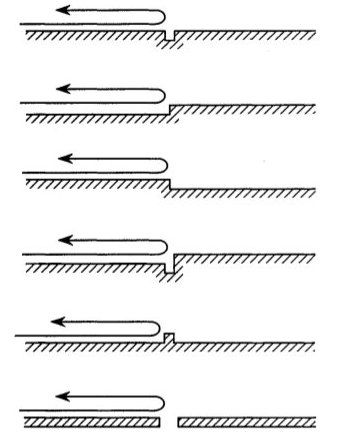

J-11 with AESA

J-10B with PESA, but it was the early prototype.

So it is better to STFU if you have nothing to contribute except trolling.