SMIC N+2, A True 7nm, Good Yields

The process is a true 7nm process in terms of density. While the engineering decisions on specific pitches are different from TSMC’s 2018 7nm, it should be considered a similar process technology, and SMIC is at worst only a handful years behind TSMC. One could argue that SMIC is at most only a few years behind Intel and Samsung despite restrictions. As SMIC is replicating what has been done elsewhere, the gap could be even narrower due to their excellent engineering pool from mainland China as well as many courted immigrants from Taiwan that were formerly employed by TSMC.

As mentioned earlier it is on par with Samsung’s 4LPX in performance and power. The big questions are

yield and volume. While some pundits claim the yield is only 10%, we don’t believe that. In fact, we believe that SMIC’s process has good yield. There’s no definitive number here, but there are some data points that indicate this.

Why? We’ve heard a few soft remarks from our sources in China that yield is good. Allegedly their D0 is currently about ~0.14. For reference, TSMC’s N5 and N6 nodes are about half that. TSMC of course is the gold standard, and Samsung/Intel “7nm” are closer although still ahead of what SMIC has achieved. Yield being this decent already is a huge flag that the SMIC N+2 process technology is healthy and developing. Parametric yield is the more important, unknown metric. But hearsay isn’t enough on its own.

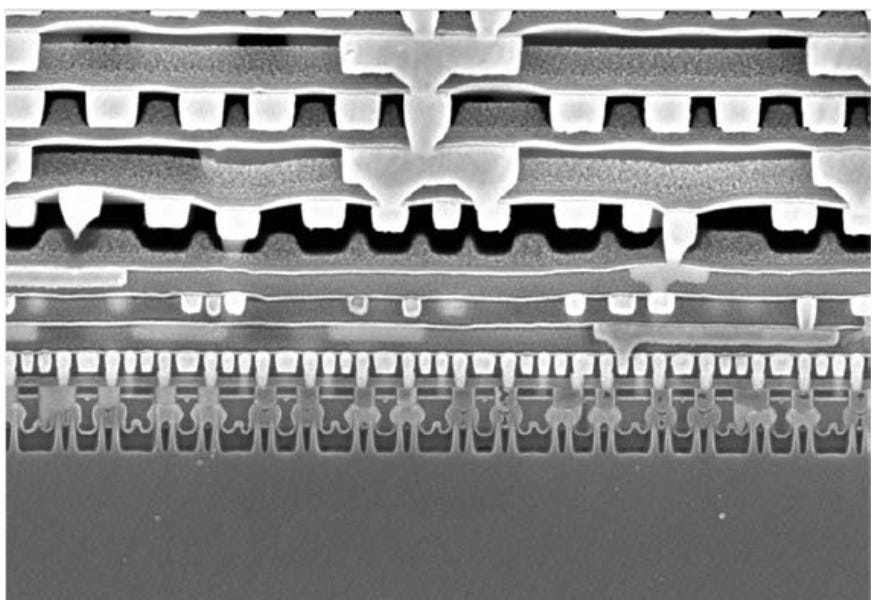

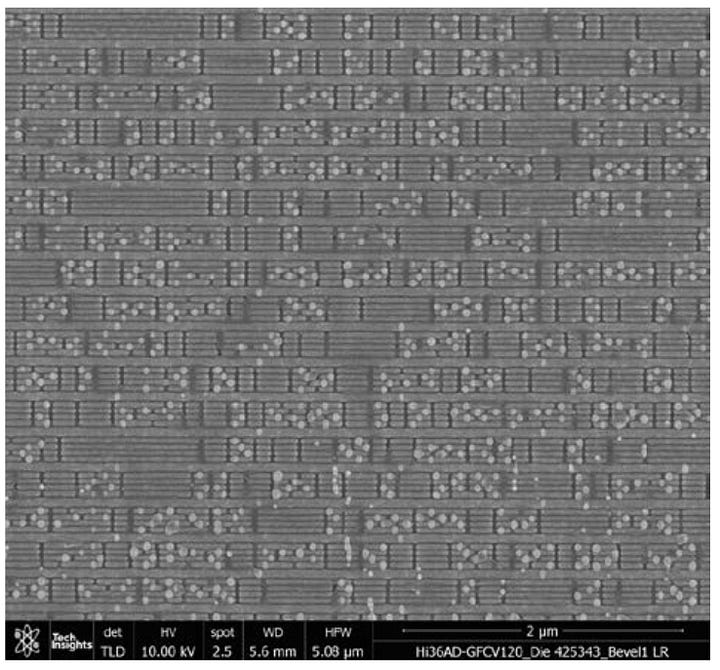

For more tangible evidence, the channels, gates, and drains on the FinFETs as well as the contacts and lower metal layers look fairly clean. A process with low yield probably won't look as uniform. See these images from the

TechInsights public brief. We recommend looking at their full teardown for more images and the exact pitches.

The last reason is related to the apparent binning of the chip. "Binning" in semiconductor manufacturing refers to the process of sorting and categorizing integrated circuits (like CPUs or GPUs) based on their performance and quality after they have been manufactured and tested. While chips can have defective transistors, called catastrophic yield, in many cases, working transistors still fail various performance and power tests. This is known as parametric yield. If a process technology has low parametric yield, the firm managing yield for the chip can make the binning process less stringent to improve the parametric yield. More chips can pass various tests, but it also leads to higher variability.

This has been done with mobile chips that yielded poorly in the past, for example the Qualcomm S8G1 on Samsung’s 4LPX. In the case of the S8G1, different devices with the same chip would have differences upwards of 10% on fully heat soaked devices in the same environmental conditions. While we haven’t seen rigorous testing of many devices in the same environment, there is enough on various Chinese forums to show that device to device variation is quite low.

None of this is bullet proof, but we believe that SMIC has good yield, and the 10% yield number some pundits have said is nonsense to downplay the significance. This is a real high volume production process technology. Just like Apple is the guinea pig for TSMC process nodes and helps them ramp and achieve high yield, Huawei will likewise help SMIC in the same way.

As a reminder, Huawei released the

first TSMC N5 produced chip, so this is a role they are very capable of playing. In two years, SMIC will likely be able to produce large monolithic dies for AI and networking applications. This is a similar time scale to what

Broadcom and Nvidia’s transition to new process technologies.

......

Continuing above article.

Btw, I just know how the processor was made.

It explains why my Intel Core i7 benchmark result is not the same as someone's posted online. I thought my Windows, motherboard, RAM, etc are the causes. It turns out the same Core i7 will have different results, because of yield factor (failure in production). If one processor turns out to be well produced, it will have higher performance (less defects). And no processor is the same because of defection.

The same smartphone can have different benchmark results, even thou all of them are brand new, tested right away out of the box.