How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Arjun-II MBT development l Updates & discussion.

- Thread starter Kompromat

- Start date

Water Car Engineer

ELITE MEMBER

- Joined

- Sep 25, 2010

- Messages

- 13,310

- Reaction score

- 8

- Country

- Location

This thing is a bit more compact in size, but pretty much the same design.

Water Car Engineer

ELITE MEMBER

- Joined

- Sep 25, 2010

- Messages

- 13,310

- Reaction score

- 8

- Country

- Location

For Bharat Pack?

gslv mk3

BANNED

- Joined

- Aug 4, 2012

- Messages

- 13,819

- Reaction score

- -18

- Country

- Location

For Bharat Pack?

That program is still active ?

Vertiti Scrutator

FULL MEMBER

- Joined

- Aug 25, 2016

- Messages

- 163

- Reaction score

- 0

- Country

- Location

It's one of the highest priority projects (National mission mode)!!!That program is still active ?

gslv mk3

BANNED

- Joined

- Aug 4, 2012

- Messages

- 13,819

- Reaction score

- -18

- Country

- Location

It's one of the highest priority projects (National mission mode)!!!

There wasn't any news of it lately

Water Car Engineer

ELITE MEMBER

- Joined

- Sep 25, 2010

- Messages

- 13,310

- Reaction score

- 8

- Country

- Location

gslv mk3

BANNED

- Joined

- Aug 4, 2012

- Messages

- 13,819

- Reaction score

- -18

- Country

- Location

Very much so.

The most powerful industrial/marine engine ever developed in India is Kirloskar's DV series, 1200 HP. So this doesn't look hard.

Water Car Engineer

ELITE MEMBER

- Joined

- Sep 25, 2010

- Messages

- 13,310

- Reaction score

- 8

- Country

- Location

Water Car Engineer

ELITE MEMBER

- Joined

- Sep 25, 2010

- Messages

- 13,310

- Reaction score

- 8

- Country

- Location

Water Car Engineer

ELITE MEMBER

- Joined

- Sep 25, 2010

- Messages

- 13,310

- Reaction score

- 8

- Country

- Location

The RCWS is armed with the 12.7 mm Russian NSVT heavy machine gun (MG), but other weapons can also be fitted, such as a 7.62 mm MG. The RCWS is designed to engage air and ground targets and is stabilised on two axes, with automated target tracking and a fire-control system.

The ammunition box is fitted on the right side of the system and the target acquisition and tracking module is located to the left. The latter includes a day camera, thermal imager, and a laser rangefinder. The day optical sensor has a range of 4 km, while the night sight has a range of 2 km.

The complete system weighs about 200 kg, including the weapon and ammunition. The ammunition box will contain approximately 200 rounds.

The RCWS has received clearance for export.

http://www.janes.com/article/67714/aero-india-2017-bel-details-rcws-for-arjun-mk-ii

Trials with the new RWS - that weighs 200kg - were successfully completed late last year. A BEL spokesman said seven months were spent on development, and a further 18 months on trials.

The RWS means tank crewmen do not need to expose themselves by leaving the safety of their tank to operate the turret-mounted weapon. It is also planned to fit the system to armoured repair and recovery versions of the Arjun.

https://www.shephardmedia.com/news/landwarfareintl/aero-india-2017-bel-completes-rws-arjun/

Water Car Engineer

ELITE MEMBER

- Joined

- Sep 25, 2010

- Messages

- 13,310

- Reaction score

- 8

- Country

- Location

Tank Ex, T72 CIA, Arjun Mark 1

Mark 2

Last edited:

Water Car Engineer

ELITE MEMBER

- Joined

- Sep 25, 2010

- Messages

- 13,310

- Reaction score

- 8

- Country

- Location

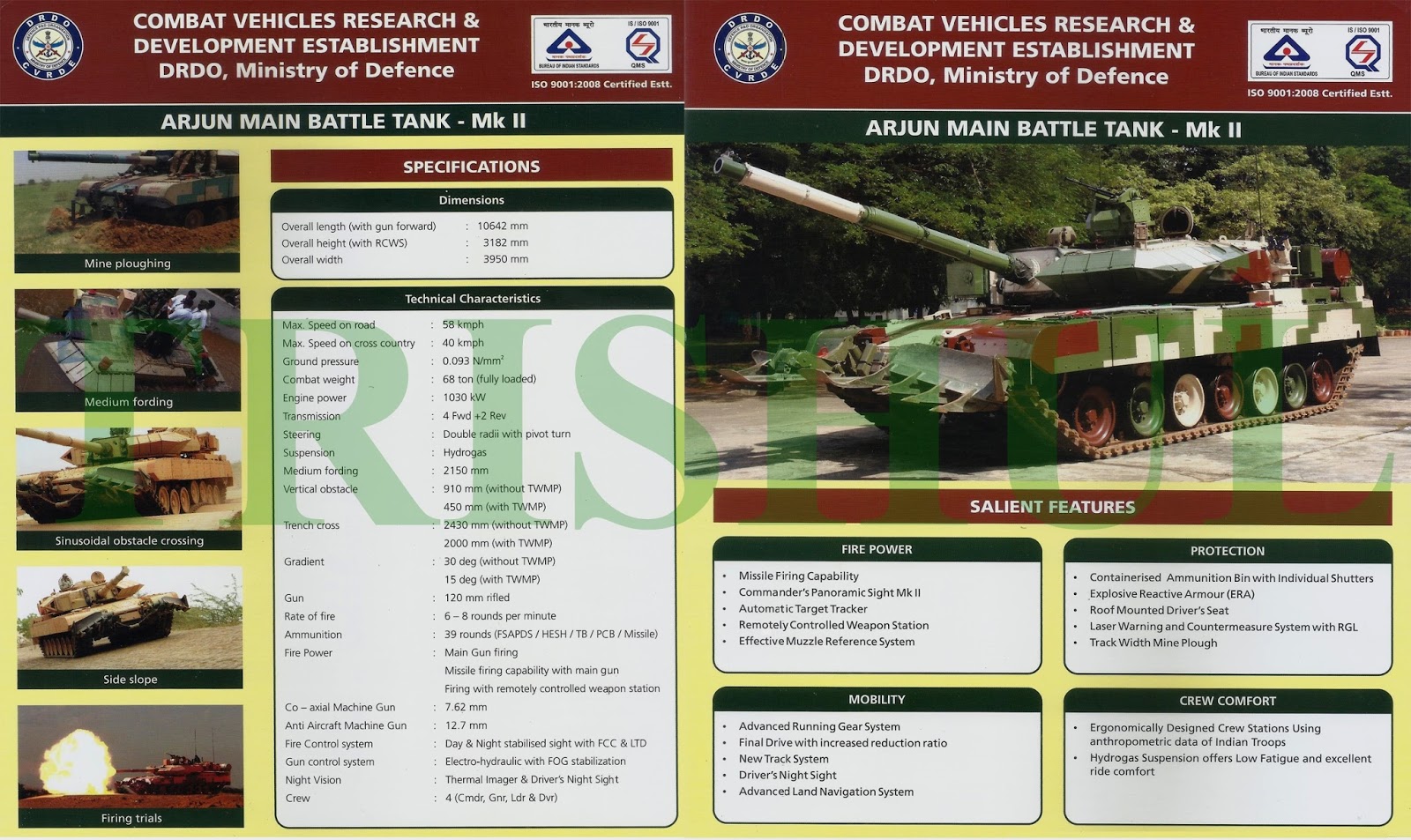

Contrary to widespread speculation, the Indian Army (IA) has not forsaken or given up on the Arjun Mk.2 main battle tank (MBT). Instead, for the past four years, the IA’s Directorate General of Mechanised Warfare has been overseeing a collective developmental effort involving the DRDO, and the MoD-owned defence public-sector undertakings and private-sector OEMs that will in the near future result in a fully-loaded 60-tonne MBT armed with a 120mm smoothbore cannon while retaining the existing 1,400hp powerpack.

For starters, the baseline hull of the Arjun Mk.2 will no longer be built with imported low-carbon, nickel-chromium-molybdenum rolled homogeneous armor (RHA) steel, but with lighter high-nitrogen steel (HNS) whose production technology has been mastered by the DRDO’s Hyderabad-based Defence Metallurgical Research Laboratory (DMRL) and has been transferred to Jindal Stainless Steel Ltd (Hisar). HNS will also be used by TATA Motors Ltd for producing the 83 Kestrel 8 x 8 armoured personnel carriers already on order.

==============================================================

To ensure optimal weight budgeting during the production engineering stage, the CVRDE has contracted Dynamatic Technologies Ltd, which specialises in complex, five-axis robotic machining, as well as in converting two-dimension paper blueprints into three-dimension computer model that are more precise, and have tighter tolerances. Digitising the drawings creates a baseline configuration for greater accuracy. This in turn streamlines manufacturing, since conventional manufacturing based on two-dimensional paper blueprints tend to leave tiny gaps between the different components of an assembly that were filled with shims, leading to increased weight. But by digitising blueprints, those tiny gaps can be entirely eliminated during the manufacturing process.

Under another weight-reduction exercise, the CVRDE has contracted the Alicon Group for building all-aluminium road-wheels and ventilators for not only the Arjun Mk.2, but also for the IA’s existing upgraded T-72CIA medium tanks.They will replace the all-steel road-wheels built bySundaram Industries for the Arjun Mk.1A.

Similarly, TATA Power SED has been contracted for producing all-electric turret stabilisation/traverse systems, in place of the existing electro-hydraulic system.

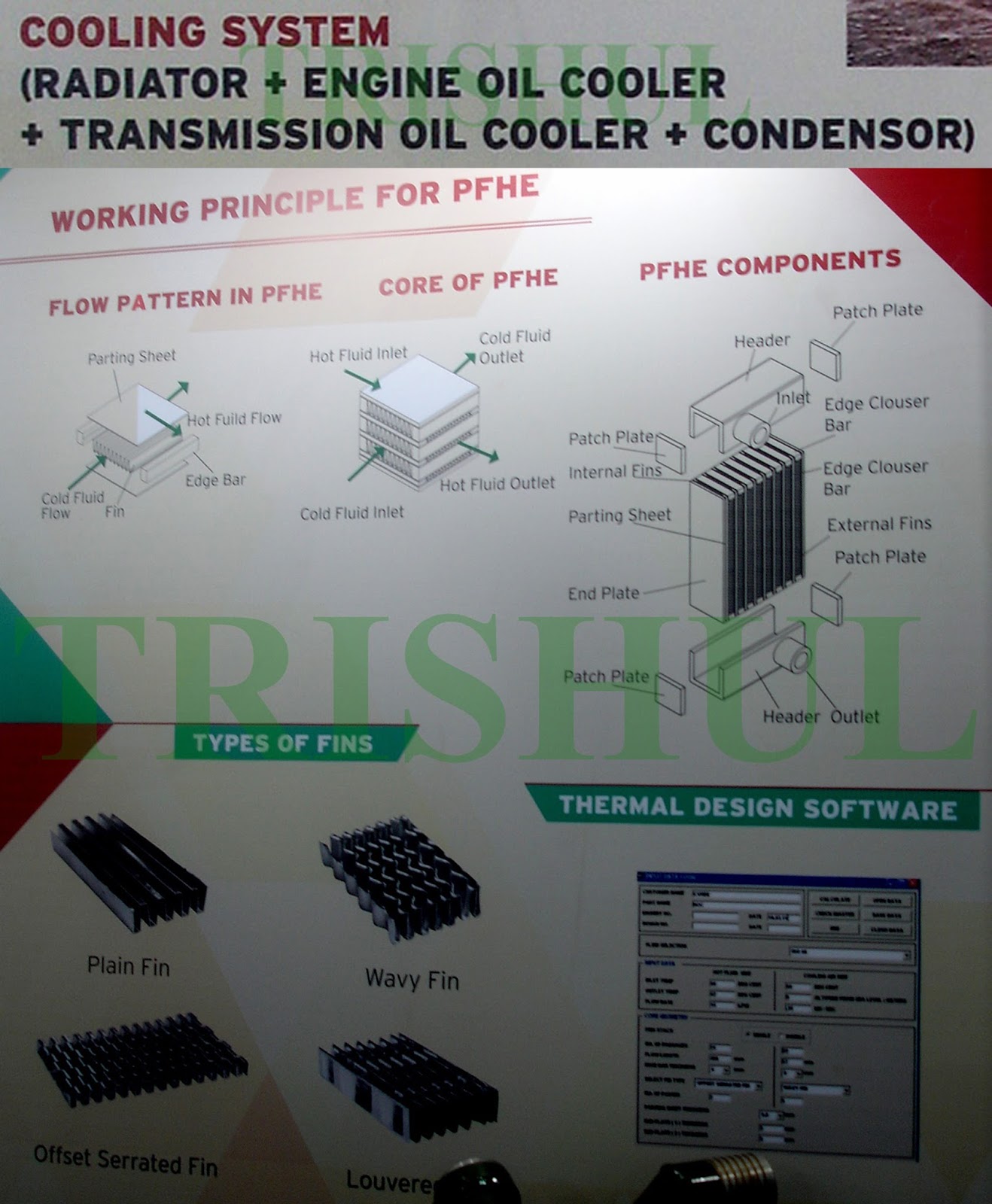

New cooling system for existing 1400hp engine.

http://trishul-trident.blogspot.com/2017/03/arjun-mk2-mbt-now-firm-reality.html

Last edited:

Water Car Engineer

ELITE MEMBER

- Joined

- Sep 25, 2010

- Messages

- 13,310

- Reaction score

- 8

- Country

- Location

Asper Gupta, the latest fsapds achieved 600mm+ penetration against RHA. They are trying to achieve 650mm+. Rifle bore is being dumped, because the HESH round is being replaced with new thermobaric and penetration timed delay rounds.

PCB

Thermo

PCB

Thermo

Similar threads

- Replies

- 2

- Views

- 2K

- Replies

- 0

- Views

- 2K

- Replies

- 12

- Views

- 2K

- Replies

- 8

- Views

- 11K