Hexciter

FULL MEMBER

- Joined

- Jun 18, 2014

- Messages

- 1,781

- Reaction score

- 0

- Country

- Location

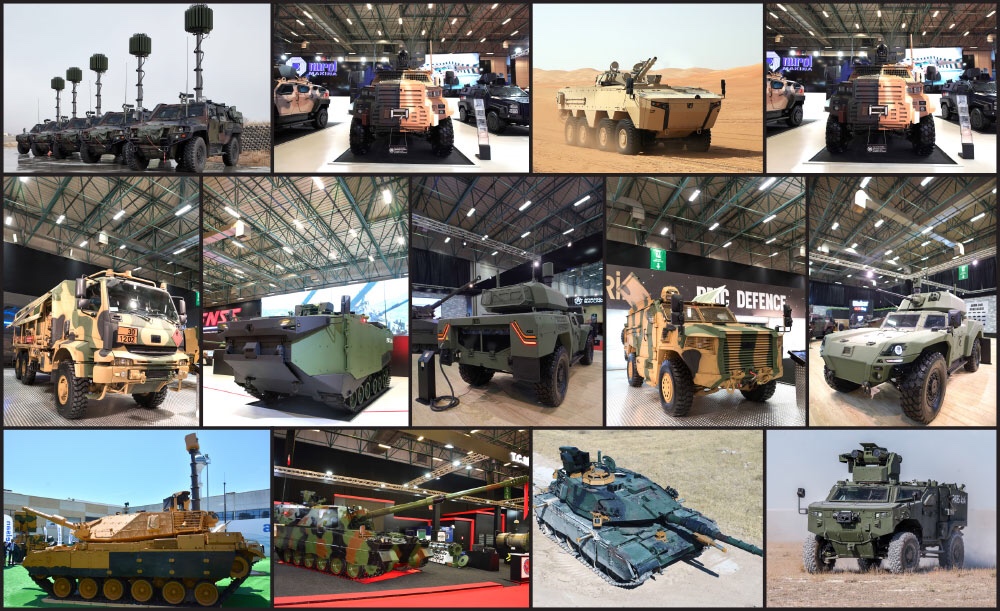

A Look at the Turkish Land Platforms Sector and Its NATO-Standard Indigenous Solutions

by İbrahim SÜNNETÇİ

During recent years Turkey’s domestic defence industry has reached such a level of capability that it can nowadays meet around 70% of the military system requirements of the Turkish Armed Forces (TAF). Turkey’s defence and security procurement agency the Presidency of Defence Industries (SSB), has been meeting the TAF’s wheeled armored vehicles requirement from local sources since late 1980s. As one of the strongest sectors of the Turkish Defence and Aerospace Industry, the Land Platforms Sector is now able to meet almost all of the Turkish Land Forces (TLF), Gendarmerie General Command (GGC) and Security General Directorate (SGD/Turkish National Police)’s requirements for tracked and wheeled armored vehicles with indigenous solutions. The next target in this field is the design, development and manufacture of a 3+ Generation Main Battle Tank (MBT) and New Generation Armored Wheeled Vehicles with an indigenous, locally manufactured power pack and armor steel.

Turkey has traditionally looked to its domestic suppliers to meet the TAF’s Land Platforms requirements, which has enabled the Sector to develop a comprehensive range of products, ranging from tactical wheeled vehicles (4x4, 6x6, 8x8 and 6x4), tactical wheeled armored vehicles (4x4, 6x6 and 8x8), armored reconnaissance vehicles (tracked and wheeled), armored internal security vehicles, mine protected vehicles, mobile floating assault bridges, riot control vehicles, amphibious armored combat earthmovers, armored combat vehicles and the ALTAY MBT, as well as modernization and upgrade solutions for APCs, ACVs and MBTs. Locally produced wheeled armored vehicles (WAVs) especially the Otokar’s 4x4 COBRA-I and COBRA-II, FNSS’ ACV-15 and KUNDUZ Amphibious Armored Combat Earthmover, Nurol Makina ve Sanayi (NMS)’s EJDER YALÇIN-I/II/III and BMC’s KIRPI MRAPs have been playing important role in Turkey’s war against the terrorist organization PKK and thanks to their high protection they saved the lives of many soldiers during recent operations by withstanding several roadside and IED bomb attacks.

The backbone of the Turkish Land Platforms/Systems sector is formed by private companies such as Otokar, FNSS, BMC, Nurol Makina ve Sanayi (NMS), Anadolu Isuzu & Anadolu Savunma, Katmerciler and Tümosan. Military Factories, which have played a key role in Main Battle Tank Modernization projects such as the Leopard 1T and M60T programs and are now providing maintenance services to the tracked and wheeled vehicles of the Turkish Land Forces (TLF) have been affiliated under the Turkish Ministry of National Defence (MoND) as of November 9, 2016. The 1st Main Maintenance Factory Directorate (formerly known as 1st Main Maintenance Centre) in Adapazarı and the 2nd Main Maintenance Factory Directorate (former 2nd Main Maintenance Center Command) in Kayseri are now operated by the MoND General Directorate of Military Factories (AFGM). Established with State of Emergency Decree Law No. 696 issued on December 24, 2017 Military Factory and Shipyard Management Incorporated Company (ASFAT Inc.) is authorized to utilize 27 Military Factories and 3 Military Shipyards and labor capacity of nearly 20,000 people. According to State of Emergency Decree Law No. 696, ASFAT will be able to submit offers to foreign and domestic tenders taking advantage of military factory and military shipyard capabilities. ASFAT is completely owned by the Undersecretariat of Treasury and will be monitored by the Turkish MoND. ASFAT Inc. will be able the use all military infrastructure, platform, ammunition, subsystems and test facilities by the approval of MoND.

Turkey’s top Main Battle Tank (MBT) maintenance and modernization factory the 1st Main Maintenance Factory Directorate, also known as “Arifiye Tank Tracks Factory” in Arifiye, Adapazarı had been included in the scope of privatization program for the 25 year operational period with a Presidential Decree (Decree No: 481) issued in the Official Gazette on December 21, 2018 as part of the ALTAY MBT Serial Production Project. The decree requires the finalization of privatization of the factory until December 31, 2019. According to original plan, the 1st Main Maintenance Factory Directorate would be leased to BMC, a joint Turkish-Qatari venture that manufactures armored vehicles and Prime Contractor of the ALTAY MBT Serial Production Project, for a period of 25 years and Serial production activities would take place at this factory. Under the deal, BMC would make an initial investment of US$ 40 to US$ 50 Million to modernize the MBT assembly and production unit at the 1st Main Maintenance Factory Directorate. BMC plans to convert the military factory into a serial production unit for the ALTAY MBT, Turkey’s first indigenous, new-generation MBT. Speaking at the groundbreaking ceremony of the BMC’s Sakarya Karasu Factory, also known as the “BMC Production and Technology Base” on January 13, 2019 President Recep Tayyip ERDOĞAN stressed that the decision about the 1st Main Maintenance Factory Directorate in Arifiye is not “privatization” but rather the transfer of management rights to BMC within certain conditions, periods, and restrictions. However, the Turkish Government’s decision to privatize and lease of the 1st Main Maintenance Factory Directorate operated under the MoND-controlled General Directorate of Military Factories (AFGM) to the private company BMC drew strong criticism in Turkish public opinion and in the end it was decided to transfer the 1st Main Maintenance Factory Directorate to ASFAT Inc. According to the Turkish media, a transfer procedure should take place on August 21, 2019 and the workers’ wages will be paid by ASFAT Inc. as of September 14th. It is stated that ASFAT, which undertakes the transfer, will either directly rent the factory to BMC or will let BMC run it within certain conditions, periods, and restrictions. Since its purchase by Turkish and Qatari partners for US$ 360 Million following a tender held in early 2014, BMC has been working as part of the strategic partnership between Turkey and Qatar.

According to the Turkish Defence and Aerospace Industry 2018 Performance Report, prepared by the Defence Industrial Manufacturers Association (SaSaD) through the evaluation of figures obtained from 87-member companies and issued during the first half of 2019, the total employment of the Turkish Defence and Aerospace Sector was 67,239 people (44,740 in 2017). The Turkish Defence and Aerospace Sector achieved a turnover of nearly US$ 8,761 Billion, imports of US$ 2,449 Billion (approximately 36% of the turnover), almost US$ 2,189 Billion in exports and a rate of US$130,304 turnover per employee in 2018. It is useful to underline that THY Technic and ASFAT Inc. data was included in the 2018 figures, for the first time, unlike previous years. According to the data provided by the Turkish Exporters’ Assembly (TIM), the Turkish Defence and Aerospace Sector realized exports of US$ 1,516.142 Billion between 1 January 2019 and 31 July 2019, in other words, during the first seven months of the year. This figure represents an increase of 37.3% compared with the same period of 2018 (US$ 1,104.334 Billion). The Turkish Defence & Aerospace Sector’s total arms exports amounted to US$ 207,861 Million in June and US$ 234,202 Million in July 2019. According to data released by the TIM, the total weight of products exported by the Turkish Defence & Aerospace Industry between 1 January 2019 and 31 July 2019 was around 23,632 tons. It was 3,441 tons in April, 5,024 tons in May, 2,891 tons in June and 3,859 tons in July 2019. So as of July 2019, the average price of Turkish Defence & Aerospace export products has reached US$64,15 per kilogram. The average price of Turkish Defence & Aerospace export products reached US$57,16 per kilogram in December 2018. The exports of the Turkish Defence and Aerospace Sector is expected to reach US$3 Billion by the end of 2019. According to TIM data, the list of the top 15 countries that imported defence and aerospace products from Turkey during January 1st – July 31st of 2019 is composed of; the U.S. (US$ 465,513 Million), Oman (around US$ 158,405 Million, mainly stemming from FNSS PARS III ACV deliveries to the Royal Omani Army), Germany (around US$ 151,764 Million), Qatar (around US$ 134,640 Million to stem from Nurol Makina and BMC wheeled armored vehicles and fast intervention boats sales/deliveries to the Qatar Emiri Armed Forces), UAE (US$ 63,323 Million mainly stemming from Otokar’s RABDAN 8x8 III ACV deliveries to the UAE Army), the Netherlands (US$ 49,468 Million), India (around US$ 40,434 Million), the UK (US$ 34,138 Million), Poland (US$ 29,236 Million), Saudi Arabia (around US$ 21,997 Million), Azerbaijan (around US$ 19,869 Million), France (around US$ 20,169 Million), Switzerland (US$ 17,898 Million) and Italy (around US$ 17,5 Million).

Some Figures on the Turkish Land Platforms Sector

Realizing around 36% of the turnover, around 40% of the exports, and 33.1% of imports, the Land Platforms sector is likely the strongest sector of the Turkish Defence & Aerospace Industry. The Land Platforms Sector takes the lion’s share in the Turkish Defence & Aerospace Industry’s revenue and is placed second in terms of export rate (after Military Aviation with US$ 693 Million) and imports (after Civil Aviation with US$ 853 Million). All estimates show that the revenue and export figures of the Turkish Land Platforms Sector will grow further in 2019. The Turkish Land Platforms Sector’s revenue has increased sharply during last four years. According to SSB data, the Land Platforms Sector realized US$ 315 Million in revenue in 2010, US$ 394 Million in 2011, US$ 439 Million in 2012 and US$ 518 Million in 2013. According to the Defence Industry Assembly 2017 Annual Report prepared by the Union of Chambers and Commodity Exchanges of Turkey (TOBB), the Turkish Land Platforms Sector realized around US$ 521 Million in revenue in 2014, US$ around 1,606 Million in 2015, US$ 1,702 Million in 2016 and US$ 2,362 in 2017. According to SASAD data the Turkish Land Platforms Sector’s revenue reached US$ 2,428 Billion in 2018. The Land Platforms Sector’s exports have increased steadily during last six years. According to the Defence Industry Assembly 2017 Annual Report the Land Platforms Sector realized US$ 220,497 Million worth of exports in 2013, US$280,285 Million in 2014, US$ 733,205 Million in 2015, US$ 487,661 Million in 2016 and US$522,091 Million in 2017. According to the Turkish Defence and Aerospace Industry 2018 Performance Report, the Turkish Land Platforms Sector has realized a total of US$540,6 Million in exports of which US$528 Million went to Other Countries, US$12 Million to Europe and US$ 0,6 Million in exports to the U.S. According to SASAD data the Turkish Land Platforms Sector has realized a total of US$739 Million in imports of which US$447 Million came from Europe, US$ 180 Million came from the U.S. and US$112 Million came from the Other Countries.

Indigenization activities continue in order to further increase the domestic participation ratio within the indigenous Land Platforms Sector products. Since the critical components of the land platforms, either tracked or wheeled, such as ballistic armor, diesel engines and transmissions are procured from foreign sources (imported) the local content rate on indigenous military land platforms usually stay at around 55% (could increase to 65% with the use of indigenous turret systems) level. But critical progress has been achieved within the scope of the development of an indigenous power pack and armor steel. For instance, the 560hp diesel engine manufactured by Tümosan will be used in the SPTWAV (Special Purpose Tactical Wheeled Armored Vehicles) to be produced by FNSS. Tümosan is also developing an indigenous automatic transmission with 6 forward gears to couple with its 560hp, 6-cylinders diesel engine and also offers its automatic transmission solution for the FNSS PARS 6x6 and 8x8 İZCİ SPTWAVs but as of May 2019 no decision had yet been made for the utilization of Tümosan’s transmission on the vehicles. Moreover, a crucial step was taken towards the local production of the armor steel used in the tactical wheeled armored vehicles. According to the information received, the production of indigenous armor steel with an annual capacity of 13,000 tons will be launched at the new factory/facility named as MİLUX OY, which will start its activities in Manisa as part of Erdemir. The production capacity is planned to be increased to 20,000 tons annually after the year 2020. The raw material of the flat steel to be manufactured and processed at MİLUX OY facilities will be supplied from Erdemir and the production technology will be transferred from the MİLUX Company purchased from Finland by OYAK. The initial armor steel sheet metal samples were displayed at the company’s stand during IDEF ‘19 Fair.

Remarkable Programs and Products of the Turkish Land Platforms Sector

Speaking on the second day of 4th Land Systems Seminar, held at the METU Culture and Congress Center in Ankara November 5-6, 2018, Security Vehicles and Special Vehicle Projects Director T. Cenk ERBAY from the SSB Land Platforms Department disclosed that it has planned to procure up to 5,872 vehicles in various configurations under 10 ongoing land platforms projects to meet the requirements of Turkish end users (TAF, Security General Directorate [SGD, Turkish National Police], Gendarmerie General Command and Turkish Coast Guard Command). The SSB Land Platforms Department currently is carrying out 10 land platforms projects namely;

New Generation Light Armored Vehicles (NGLAV) Project

This project covers the procurement of a total of 2,962 light armored tracked (1,800 vehicles both in amphibious and non-amphibious configurations) and wheeled (1,1162 vehicles in 6x6 and 8x8 versions) vehicles in 52 different configurations for the Turkish land Forces Command (TLFC). Since the number of the procured vehicles is high, the Project is planned to be realized in phases. The First Phase will cover 3 different vehicle-types in 6x6 and 8x8 configurations. The RFP document for the First Phase was issued in August 2019 to potential local bidders.

Located at Teknopark Istanbul, BMC Power was selected under the New Generation Light Armored Combat Vehicle Power Pack Development Program by the DIEC on October 28, 2016 and a contract was signed between the company and the SSB on October 13, 2017. Under the program BMC Power will design, develop, test, qualify and deliver a power pack in ‘T’ configuration dubbed UTKU and incorporating a 675kW (917hp), V8 type 18-litter diesel engine coupling with an automatic transmission under a 68-month schedule. The contract become effective on January 4, 2018 and ‘To’ started. According to a BMC official, over 200 engineers including 70 foreign ones are working on the power pack. According to the SSB the 675kw UTKU engine is able to power armored vehicles with a combat weight of 40 tons.

Special Purpose Tactical Wheeled Armored Vehicles (SPTWAV) Project

This project covers the procurement of a total of 100 SPTWAVs from FNSS both in 6x6 and 8x8 configurations for the TLFC and Gendarmerie General Command (GGC). TLFC will receive 95 PARS 6x6 İZCİ (SCOOTER) and PARS 8x8 İZCİ SPTWAVs of which 30 will be in Command Vehicle, 45 in Reconnaissance (with EO/IR optics), 15 in Surveillance (with radar) and 5 in CBRN Reconnaissance configurations. The GGC will receive 5 vehicles in Armored Combat Vehicle configuration.

8x8, 10x10, 12x12 Wheeled Tank Transporter, Container Transporter and Recovery Vehicle Project

Within the scope of the Project, a total of 476 vehicles, including 134 Tank Transporter Vehicles (TTVs), 65 DROPS Container Transporter Vehicles and 277 Recovery Vehicles, will be procured to meet TLFC requirements.

As one of the local companies competing in the Project tender, BMC submitted its proposal to the SSB in the first half of 2018. The first contract regarding the demand for Tank Transporter Vehicles in 8x8 configuration was signed between the SSB and BMC, and the delivery of the 72 TUĞRA TTVs is planned to be launched in August 2019. According to BMC, the local content rate for the BMC TUĞRA TTV is at 70-75% level. At IDEF ‘19, BMC displayed the ALTAY T1 Technology Demonstrator on a TUĞRA TTV powered with 620hp engine and with a towing capacity of 120 tons. The other local bidder competing for the 8x8, 10x10 and 12x12 Wheeled Tank Transporter, Container Transporter and Recovery Vehicle Project, Anadolu Isuzu placed its proposal to the SSB on 16 April 2018. Within the scope of the Project, Anadolu Isuzu signed a Sub Contractor Contract with a total value of US$ 4,580 Million (VAT excluded) with the MPG Makina İmalat San. ve Tic. A.Ş. as part of the Partially Mine-Protected Recovery Vehicles Project and on 10 May 2019 the company notified the Public Disclosure Platform of the fact that the contract value reached US$ 13,312 Million (VAT excluded) as a result of the additional firm orders it received. According to the aforementioned contract, the deliveries of the SEYİT 8x8 Partially Mine-Protected Recovery Vehicles will be made in lots until the end of 2019. This vehicle is capable of successfully performing the tasks under tough land and road conditions and was manufactured in a way to be able to recover malfunctioned large tonnage vehicles and armored vehicles. Weighing 43,000 kg, the Partially Mine Resistant Recovery Vehicle features a climbing ability of 60% inclination, and it is capable of passing through 1,100 mm deep water as well. Featuring a 14.9 liter volume with the Cummins X15 99EPA 600 engine, the 8x8 partially mine resistant recovery vehicle has 600hp and it can reach a speed of 80 km/h. With a range over 500 km, the aforementioned vehicle will be included in the inventory soon and will start to operate in the TAF.

Weapon Carrier Vehicle (STA/WCV) Project

Under the Weapon Carrier/Anti-Tank Vehicle (WCV) Program, a total of 260 (184 in tracked and 76 in wheeled configurations) anti-tank vehicles to be integrated with a Remotely Operated Anti-Tank Turret, will be procured from FNSS in order to carry the new generation KORNET-E Anti-Tank Guided Missile Systems (ATGM) currently in service of the TLFC and also for those to be acquired by the SSB from Roketsan under the MIZRAK-O/OMTAS Project. On 27 June 2016 the SSB awarded a contract to FNSS to deliver 186 WCVs based on the KAPLAN-10 tracked armored vehicle and 76 WCVs based on the PARS 4x4 Wheeled Armored Vehicle (WAV). The contract became effective on October 14, 2016. 80 of the KAPLAN-10 WCVs will be equipped with KORNET-E ATGMs and remaining 104 will be equipped with Roketsan’s MIZRAK-O/OMTAS ATGMs. All 76 PARS 4x4 WCVs will be equipped with Roketsan’s MIZRAK-O/OMTAS ATGMs. Under the contract, design development and prototype qualification efforts for KAPLAN-10 and PARS 4x4 WCVs were completed in 2018. Under the Project qualification tests for both vehicles are still on going. As part of the qualification tests on 13 February 2019 at the Karapinar live firing range in Konya, FNSS successfully conducted the first firing test of the OMTAS missile from the Kaplan WCV. Deliveries for KAPLAN-10 WCVs was scheduled to be launched in the first of 2019 and PARS 4x4 WCVs during the second half of 2019. Serial Production and the delivery of 260 WCVs to the TLFC are to be completed by the first quarter of 2021. Both the KAPLAN-10 and PARS 4x4 WCVs will have amphibious capabilities and will be fitted with an unmanned, Anti-Tank Remote Controlled Turret (ARCT) carrying just two (four were planned in the beginning) KORNET-E or MIZRAK-O/OMTAS ATGMs and a 7,62x51mm machine gun.

Tactical Wheeled Armored Vehicles (TTZA/WAVs) Project

Within the scope of the Project, a total of 713 VURAN 4x4 Tactical WAVs vehicles will be procured from BMC for the TLFC (512), GGC (200, including an undisclosed number of 120mm Automatic Mortar Vehicles dubbed as FATİH) and Coast Guard Command (CGC, 1). The FATİH Automatic Mortar Vehicle is equipped with Aselsan’s ALKAR AKS-120 automatic mortar system. In the context of the fight against terrorism and border security missions; VURAN WAVs will perform tasks such as sensitive point or facility protection, patrols between military outposts, convoy protection, responsibility area, point and road reckon and physical border security. The deliveries of VURAN 4x4 Tactical WAVs to the TLFC started in July 2019 and according to news published by the Anatolian Agency website as of 19 August 2019 the number of delivered vehicles has reached 90. The VURAN WAV features a monocoque-type armored design for the crew compartment that reduces weight for a given amount of armor compared to vehicles to which armor has been attached to an underlying frame. The V-shaped hull is made of all-welded steel armor construction that provides the occupants with protection against 5.56 × 45 mm small arms fire, although protection against 7.62 × 51 mm armor-piercing small arms fire is also available. The basic layout of the VURAN is similar to the BMC AMAZON with the engine at the front, the crew in the middle and the troop’s compartment at the rear. The vehicle can carry a total of nine soldiers. Some of the VURAN WAVs will be fitted with the SARP Remote-Controlled Weapon Station (RCWS) designed and manufactures by Aselsan. BMC has also developed and displayed the remote-controlled version of the AMAZON WAV. BMC also secured a contract to deliver 50 KIRPI-II MRAPs and 35 AMAZON 4x4 Multipurpose WAVs to Qatar during the Doha International Maritime Defence Exhibition and Conference (DIMDEX 2018), which was held at the Qatar National Convention Center in Qatar’s capital Doha March 12-14, 2018.

Tactical Wheeled Vehicles-2 (TTA-2) Project

The SSB awarded a contract to BMC under the Tactical Wheeled Vehicle-2 (TTA-2) Project on August 8, 2017 for the procurement of 529 New Generation KIRPI (KIRPI-II) MRAPs. Deliveries of the KIRPI-II (HEDGEHOG-II) MRAPs commenced in 2017. Under the contract the TLFC will receive 329 KIRPI-II 4x4 MRAPS and GGC will receive 200 KIRPI-II MRAPS. As of December 2018, over 290 KIRPI-II MRAP and over 30 KIRPI-II Ambulance vehicles were delivered. Under the Tactical Wheeled Vehicle-1 (TTA-1) Project the TLFC received over 610 KIRPI-Is and the GGC received over 300 KIRPI-Is. The SGD also procured over 100 KIRPI-I vehicles. The total number of KIRPI-I MRAPS in TLFC, GGC and SGD inventory has reached 1,028 as of October 2017. Some of the KIRPI-I and KIRPI-II MRAPS in TLFC, GGC and SGD (operates over 200 KIRPI) services are integrated with Aselsan’s SARP 12.7mm and Dual SARP (can be armed with 7.62mm and 12.7mm machine guns and a 40mm automatic grenade launcher) RCWSs. Compared to KIRPI-I (fitted with leaf spring suspension system), KIRPI-II has an independent suspension system and also features composite armor, manufactured by a local company.

KIRPI-II 4x4 with Independent Suspension stands out with its unibody armored cabin and special armored windshields, shock-absorber seats, weapon-station and the emergency exit hatch. Powered by an 8.9 liter, 375hp (previous batch vehicles in TLFC, GGC and Tunisian Army services are powered by 350hp version of the same engine) Cummins ISL9E3 turbo diesel engine KIRPI has a 13 troop capacity including the three-man crew (driver, commander and gunner). With an empty weight of 19,050kg and combat weight of 20,825kg KIRPI-II 4x4 features STANAG 4569 Level 4 mine and Level 3 ballistic protections as well as a spall liner. The KIRPI-II can travel through 80cm (120cm optional) of water, negotiating 30° side slopes and a 60% gradient. Having a length of 7,375m, width of 2,865m and height of 3,81m the KIRPI-II MRAP can attain a maximum speed of 100km/h and a cruising range of 750km.

Battlefield Fuel Tanker (AKTAN) Project

Within the scope of the Project, a total of 84 Battlefield Fuel Tankers (AKTAN, 17 of them for helicopter fuel supply and 67 of them for land vehicles fuel supply) have been procured from BMC to meet both the TLFC and the Turkish Naval Forces Command’s requirements. Under a contract awarded by the SSB on June 28, 2015 BMC completed deliveries in 2018. 83 AKTAN BMC 440 6x6 vehicles have been delivered to the TLFC and 1 AKTAN BMC 440 6x6 has been delivered to TNFC. It can be air transported onboard an A400M military transport aircraft. The AKTAN BMC 440 6x6 vehicle can simultaneously support fuel oil for four air/land vehicles and is designed and engineered to maximize the operational power of the Armed Forces. BMC previously delivered a total of 46 Water Tankers in 8x2 configuration to the TLFC.

New Generation Criminal Investigation Vehicle (KIRAÇ) Project

Under the New Generation Criminal Investigation Vehicle (KIRAÇ) Project, Katmerciler secured a contract from the SSB in June 2017. The contract calls for the design, development and delivery of 110 Criminal Investigation Vehicles and 10 Laboratory Vehicles to the SGD Criminal Department within a two-year schedule. Katmerciler completed the manufacture of prototype vehicles in 2018, following the completion of qualification tests Serial production of the KIRAÇ vehicles was initiated in early 2019. Katmerciler displayed one of the KIRAÇ vehicles at its stand during the IDEF ‘19 Fair. Manufactured in 4x4 configuration the KIRAC vehicle features an independent suspension system, hub reduction differential lock, diesel turbo intercooler, fully automatic transmission with torque convertor and ballistic and mine protection. The KIRAÇ New Generation Criminal Investigation Vehicle has a unique design, which can be configured as an armored personnel carrier, command control vehicle and an internal security vehicle. Based on the configuration, it can carry up to 27+1+1 personnel. The fully independent suspension system and 4x4 characteristics with automatic transmission gives excellent mobility on all terrain and weather conditions.

SGD Armored Tactical Vehicle-1 (EGM ZTA-1) Project

Within the scope of the Project, a total of 280 EJDER YALÇIN Block III 4x4 Tactical Wheeled Armored Vehicles have been procured from Nurol Makina to meet SGD (180) and GGC (100) requirements. Deliveries to the SGD were completed during the first half of 2017 and all of the vehicles were integrated with Aselsan SARP RCWS armed with a 7,62mm machine gun. The first batch of 30 EJDER YALÇIN Block III was delivered to GGC in May 2017.

EJDER YALÇIN, a new member of the EJDER Family of wheeled armored vehicles, is a 4x4 tactical armored combat vehicle designed and manufactured by Nurol Makina. Design studies on the vehicle were initiated in the last quarter of 2012 and a pre-prototype of the base vehicle was exhibited at IDEF ‘13. Mass production of the vehicle began in May 2014. Featuring a V-shaped hull design, integrating floating floor plates and blast mitigation seats to provide protection against mines and improvised explosive devices (IED) the vehicle accommodates up to 11 personnel. The vehicle features easy-to-enter and exit door configurations for the crew. Other optional equipment includes a rescue winch, day and night-vision systems, rear ramp, and a fire extinguish and explosion suppression system for the crew compartment. The base vehicle has a length of 5,42m, width of 2,48m and a height of 23m. Its gross weight ranges between 12,000kg and 14,000kg, and payload carrying capacity is up to 4t. The Block I and Block II versions of EJDER YALÇIN are fitted with a Cummins engine, which produces a maximum power of 300hp at 2,100rpm. The engine is coupled to fully automatic transmission with a hydrodynamic torque converter. But in Block III the engine power is uprated and increased to 375hp. The EJDER YALÇIN has a maximum speed of 110km/h and a cruising range of 600km. It can accelerate from 0km/h to 40km/h within six seconds.

Nurol Makina won its first export contract from Tunisia for its EJDER YALÇIN Block III 4x4 WAV in early 2017. It was followed by orders from Uzbekistan, Qatar, Senegal, Hungary and South Sudan. Hungary also ordered a number of YÖRÜK 4x4 WAVs from Nurol Makina. According to sources Nurol Makina will deliver 75+ 150 EJDER YALÇIN vehicles to Tunisia, 1,024 vehicles to Uzbekistan, 342 vehicles to Qatar and 25 vehicles to Senegal. According to a MoU signed in October 2017 Nurol Makina will deliver 24 EJDER YALÇIN WAVs to Uzbekistan and an additional 1,000 vehicles to be produced in Uzbekistan in cooperation with the local firm UzAuto. The delivery ceremony of the 24 EJDER YALÇIN WAVs to Uzbekistan Army took place on August 2, 2019 in Uzbekistan. During DIMDEX 2018, Nurol Makina also secured a contract to deliver 214 YÖRÜK (formerly named NMS) 4x4 Wheeled Light Armored Vehicles to the Qatar Emiri Special Forces, to be armed with SARP RCWS, ATGM launcher and IGLA SAM launcher of Aselsan. Deliveries of the YÖRÜK 4x4 WAVs have been initiated and are scheduled to be completed in two years. On June 8th, 2018 Aselsan secured a contract valued at around US$150 Million from Nurol Makina to deliver an undisclosed number of SARP RCWSs, Kornet-E ATGM Launcher Systems and IGLA SAM Launcher Systems to equip the Qatar Emiri Special Forces’ YÖRUK 4x4 Wheeled Armored Vehicles (WAVs).

SGD Armored Tactical Vehicle-2 (EGM ZTA-2) Project

In June 2016 Otokar secured a contract valued at €106.1 Million for the delivery of 220 COBRA-II WAVs to the SGD. Some of the vehicles are armed with Aselsan SARP RCWS. The SSB also procured further 100 COBRA-IIs for the GGC. Under the project the SSB ordered a further 17 COBRA-II vehicles in December 2018 to meet the SGD’s additional vehicles requirement. Otokar completed delivery of the first batch of COBRA-II WAVs in Special Mission configuration (able to carry a remotely operated Explosive Ordnance Disposal [EOD] Robot inside the fuselage) to the SGD in December, the second batch in May 2019 and the last batch in June 2019.

The COBRA-II Tactical Wheeled Armored Vehicle provides an outmatched performance in a wide range of challenging terrains and climatic conditions. In addition to superior technical and tactical features, COBRA-II also offers high degree of protection and forms a base for a modular platform. Unveiled for the first time in May 2013 COBRA-II has an overall length of 5.6m, width of 2.5m and height of 2.2m. The wheelbase and ground clearance of the vehicle are 3.57m and 400mm respectively, while the gross vehicle weight is 12,000kg. The COBRA-II can negotiate a 48° approach and a 60° departure angle leading onto 60% inclines and 30% side-slopes. It is able to cross 90cm wide trenches and climb over 40cm obstacles. The COBRA-II can be fitted with either 6,7 liter, 6 cylinders 281hp water-cooled turbo diesel engine or 6,7 liter, 6 cylinders 360hp water-cooled turbo diesel engine (Turkish users’ preference) with F-34 and F-54 fuel compatibility. The COBRA-II has a top speed of 110km/h and a cruising range of 700km. Besides outstanding mobility capability and up to nine crew (including driver and commander) carrying capacity, the vehicle provides protection, firepower and mission equipment for users on different types of missions. According to an Otokar official, the local content rate in COBRA-II’s baseline version is currently at the 57% level but depending on using an indigenous turret system this percentage can be increased to 64%. Otokar utilizes ARMOX 500T armor plates (up to 7 different types of steel sheets with different chemical and physical features since they are used in different parts of vehicle fuselage) and a ceramic based automated Fully Penetrated Cooled Welding Technique (already used in ALTAY MBT Prototype Development Phase) in the manufacture of the COBRA-II fuselage. According to Otokar no other local military vehicle manufacturer utilizes this welding technique and thanks to using this new generation welding technique COBRA-II’s ballistic and mine/IED protection level is superior than its competitors. However, as this welding technique takes 2,5 times longer than other standard welding techniques, which means the vehicle has to stay on the production line longer, COBRA-II has a higher production cost compared to its counterparts on the market. Otokar, as subcontractor of Aselsan, also delivered an undisclosed number of (we estimate over 20 vehicles) COBRA-II Tactical Wheeled Armored Vehicles to the TLFC under a contract valued at US$ 40,320,000 Million for the SERHAT Counter Mortar Radars (CMR) Project signed between Aselsan and the Ministry of National Defence (MoND) on June 28, 2018. According to Aselsan, within the scope of the Project acceptance tests of the third party SERHAT CMRs on the COBRA-II Tactical WAVs were carried out during May 27-31, 2019 successfully and the radars were handed over to the TLFC.

ALTAY Project Phase-II Serial Production Project

BMC was assigned as the Main Contractor upon the decree of the Defence Industry Executive Committee (DIEC, the highest decision-making body on defence procurement in Turkey) dated 29 March 2018 under the ALTAY Project Phase-II Serial Production Project. The contractual negotiations were launched in March 2018 with the company and were completed successfully. The contract valued at Euro 3,5 Billion was signed between the SSB and BMC on 9 November 2018. Under the Serial Production Phase, a total of 500 ALTAY MBTs are expected to be procured in two batches. The first batch of the ALTAY MBT Serial Production Phase, for which the contract was awarded, covers the production of a total of 251 ALTAY MBTs in three configurations. Of the 251 ALTAY MBTs under the contract, 40 will be in T1, 210 will be in T2 and 1 will be in T3 configuration. Under the Project, BMC will receive consultancy services from Rheinmetall. According to BMC, Rheinmetall’s consultancy will focus on various points being handled by their subcontractors, and which constitute the industrialization aspect of the Project.

The T1 variant, which will have similar features with the PV-1 and PV-2 prototypes developed and manufactured by Otokar but will feature the AKKOR Active Protection System (APS) and an improved add-on armor package from Roketsan (including slat armor at the rear of the turret and the hull, thicker ERA elements at the side skirts of the hull and an add-on armor kit over the turret) is scheduled to be in service with the Turkish Land Forces 24 months following contract effectivity and deliveries shall be completed in 2021 or in 2022 (depending contract effectivity date).

Before the contract effectivity two important drawbacks should be solved. The first one is the approval of the export license by the German Government for the export of the EuroPowerpacks for the ALTAY T1 MBTs to Turkey. The second one is the selection of the facility where the Serial Production will take place. According to the information we received, depending on the result of the privatization process of the 1st Main Maintenance Factory Directorate, either the facilities at Arifiye or the facilities at Karasu will be selected for the execution of the Serial Production activities. As pointed out above, Serial Production will take place at the 1st Main Maintenance Factory Directorate in Arifiye, Adapazarı. Since BMC has committed to manufacture 6 ALTAY MBTs per month during the Serial Production Phase, modern benches to enable the company to achieve this production rate will be required. For this purpose, BMC will invest up to US$ 50 Million in the 1st Main Maintenance Factory Directorate to upgrade its manufacturing infrastructure with the installation of new generation benches at the facility. The EuroPowerpack incorporates V-12 type MTU MT883 Ka-501CR diesel engine (27,35 liters, dry weight is 1,800kg) coupled to RENK’s HSWL 295TM automatic transmission (with 5 forward and 3 reverse gears, dry weight is 2,450kg) and a cooling and air filtration system. The EuroPowerpack is installed in a ‘U’ configuration in the ALTAY MBT.

The ALTAY MBT T2 configuration will feature an increased armor system, increased protection with the isolation of ammunitions from the hull, laser guided tank ammo firing capability (for this Fire Control System should be upgraded), crew training mode and mobile camouflage net. The T2 variant is expected to begin deliveries shortly after the T1 configuration of ALTAY MBTs have been handed over. Only one ALTAY MBT prototype will be produced in T3 configuration, which will feature an unmanned turret with a bustle-mounted autoloader. The ALTAY MBT T3 configuration is scheduled for qualification in 2024, and it is understood to be intended for use in further trials and technical evaluations rather than for service with the Turkish Land Forces. The ALTAY MBT Serial Production Phase contract also includes lifecycle logistics support service and the establishment and operation of a Tank Systems Technology Center. There is also a plan for the procurement of 60 Armored Recovery Vehicle (ARV) and 50 Mine Clearance variants of the ALTAY MBT, which will be based on the T1 configuration’s chassis. On 12 March 2019 Vice Chairman of the Justice and Development Party (AKP) Ali İhsan YAVUZ disclosed that in accordance with the agreement, Qatar will buy up to 100 ALTAY MBTs from Turkey and 40 of them would be delivered to the Gulf country in the first phase. However, speaking to Defence Turkey during the IDEF ‘19 Fair a BMC official disclosed that there is no formal contract for this purchase yet.

During IDEF’19, within the scope of the project valued at EUR 3.5 Billion, ALTAY Phase-II Serial Production, Aselsan signed a subcontract with BMC with a total value of EUR 840,986.250 Million for the delivery of the following subsystems to be installed on ALTAY MBT T1 (40 tanks), T2 (210 tanks) and the prototype of ALTAY T3;

Tank Fire Control System

Tank Command Control Communication and Information System

Remote Controlled Weapon System

AKKOR Active Protection System

Tank Driver Vision System

Tank Laser Warning System

Combat Area Recognition and Identification (IFF) System

Close - Range Surveillance System

In line with the contract, the company will also conduct the delivery of the products required for the training tools to be formed for the user/maintenance training of the aforementioned systems.

At the IDEF ‘19 Fair, the ALTAY MBT T1 Demonstrator was displayed on the BMC’s TUĞRA TTV at BMC stand. Prepared within 2 months by the BMC staff at the 1st Main Maintenance Factory Directorate in Arifiye, Adapazarı, the ALTAY MBT T1 Demonstrator was based on the ALTAY PV2 prototype and featured several dummy subsystems due to the fact that their development processes were not yet completed.

There are four Aselsan AKKOR APS radars deployed at the corners of the tank turret, moreover there are many electronic units within the tank for AKKOR APS, therefore the back of the turret is slightly expanded. Manual utilization of the AKKOR APS is not considered since it is a system reacting in a duration measured with milliseconds. The tank commander switches the system on and off via the user interface (control panel) and receives data on whether the launchers (two launchers each with two cells) are full or empty. The weight of the ALTAY MBT PV2 prototype is 63.5 tons and 25 tons of this is the weight of the turret. With the installation of Roketsan’s new add-on armor and AKKOR APS on the turret and hull the combat weight of ALTAY T1 would be increased. In response to our question on whether the increase in the tank’s weight due to the additional armor package in the T1 version will affect the performance of the power pack or not, BMC representatives stated that extra changes were not necessary since the weight of the T1 configuration remained within the weight limits they projected. AKKOR APS will also be deployed in the 210 T2 model to be manufactured after the 40 T1s, but a completely different armor package will be used in this version. BMC representatives underlined that a significant amount of weight change will be faced as the main armor of the tank will also be different and added, “We cannot state a figure yet but the first 40 tanks are T1, so we have a long time before the T2 schedule. We will proceed step by step, upon the approval of the SSB”. The same power pack will be utilized in some of ALTAY T2 MBTs but according to the current plan indigenous powerpack will start to be deployed in the ALTAY MBT starting from T2 configuration. According to BMC officials, in order to compensate for the increase in weight, an indigenous diesel engine being developed by BMC Power for the ALTAY T2 MBT will be more powerful and will offer better performance than the existing 1,5000hp EuroPowerpack.

Despite the fact that the ALTAY MBT Serial Production Contract valued at Euro 3.5 Billion signed with the SSB still has not entered into effect, BMC already has launched its activities in a 5,000 m2 area at the 1st Main Maintenance Factory Directorate in Arifiye. According to the information we received from the representatives of BMC with whom we had the chance to interview during the IDEF ‘19 Fair, 100 professional BMC staff have been working on the ALTAY Project as of this April and this number is planned to be increased to 300 by the end of the year. Nearly 1,300 people are expected to be employed within the scope of the project during the Serial Production Phase with nearly 1,000 blue collar staff.

BMC signed a contract on the ALTAY MBT Power Pack with the SSB on June 13, 2018. The name BATU was given to the ALTAY MBT Power Pack to incorporate a diesel engine and automatic transmission that will be developed by BMC Power. Meanwhile, allegedly, BMC has been conducting activities in order to develop a new engine with a power capacity of 1,600hp that is based on the Fiat/Iveco MTCA V12 diesel engine with 1,270hp (950kW) power capacity and 25.8lt volume utilized in the Ariete MBT with the support of Fiat. Allegedly Fiat Company will provide support to the activities and benefit from the data acquired during the development process, and at the end of this cooperation two different engines will be revealed. The Italians will design a supercharged engine with a 1,500hp power capacity. The engine that BMC will utilize in the ALTAY MBT will feature a turbocharger for the higher power requirement.

The ALTAY MBT is operated by a crew of four, consisting of a commander, gunner, loader and driver. The commander is seated on the right side of the turret, with the gunner forward and below his position and the loader on the left side of the turret. The commander’s panoramic periscope mounted in front of the loader’s hatch. The tank’s main weapon is a 120mm 55-calibre smoothbore gun fitted with a thermal sleeve; fume extractor and a muzzle reference system. Ready to use 120mm ammunition is be stowed in the turret bustle with blow out panels in the roof. The loader’s hatch has a ring mount for a 7,62mm machine gun, and Aselsan’s SARP Remote Controlled Weapon Station (RCWS), armed with .50-calibre (12,7mm) machine gun, is mounted on the left side of the turret roof (behind the loader’s hatch), for operation by the commander. The ALTAY MBT measures 10,85m in length, 3,68m in width and 3,32m in height, with a combat weight of 63,5 tons. Thanks to its powerful EuroPowerpack, ALTAY MBT accelerates from 0 to 32km/h (0 to 20mph) in 6 seconds and attains a maximum speed of 65,5km/h, the speed and agility also helps to improve survivability. The ALTAY MBT can cruise at 450km with internal fuel.

The 3rd+ Generation ALTAY MBT also was proposed for the Royal Army of Oman (RAO)’s Modern Main Battle Tank (MBT) tender covering the procurement of 77 tanks by Otokar. The company submitted its proposal at the end of the year 2014 within the scope of the procurement program that was initiated in August 2013. The ALTAY MBT’s PV-2 prototype participated the field tests (mobility and firing tests) executed in Oman in July – August 2018. As part of the tests, 150 live firings were executed against fixed and mobile targets with the ALTAY PV2 MBT and a 4,500km distance was covered in desert conditions. According to the information we received, ALTAY MBT displayed successful performance in the tests that were conducted in Oman. In the tender, ALTAY MBT’s most serious competitor is German Leopard 2A7 MBT. During the 10th Ambassadors Conference held by the SSB on 16 August 2018, President of Defence Industries Prof. İsmail DEMİR declared that one of the ALTAY prototypes succeeded in the field tests by an undisclosed country (Oman) and he said that the countries to which ALTAY MBT has export potential are Oman, Qatar, Bahrain, Saudi Arabia, Malaysia and Indonesia.

M60 and Leopard 2A4 MBT Modernization

Soon after several Turkish M60A3, M60T and Leopard 2A4 MBTS were hit by Kornet-E/AT-14, Milan, TOW-II, 9K115-2 Metis-M and Fagot/AT-4 Anti Tank Guided Missiles (ATGMs) launched by Islamic State (ISIS) and YPG/PKK militants during Operation Euphrates Shield (carried out during August 24, 2016 – March 29, 2017) in Syria, in January 2017 the SSB launched a tender for the modernization of 169 M60T, 40 M60A3 and 81 Leopard 2A4 MBTs to improve their protection level and increase their survivability against modern ATGM threats.

The FIRAT-M60T Modernization Project was launched for the modernization of M60T MBTs to increase their survivability against modern ATGM ATGM (Anti-Tank Guided Missile) threats, to increase their firepower and their situational awareness. The Main Contract valued at EUR 109,245 Million + TL 25 Million was signed between the SSB and Aselsan on 11 May 2017, and the Amendment no 1 to the contract valued at EUR 96.7 Million + TL 25 Million was signed on 24 July 2018. Under the FIRAT-M60T Modernization Project , the Main Contractor Aselsan, in cooperation with the 2nd Main Maintenance Factory Directorate, integrated a 12.7mm SARP RCWS, YAMGÖZ Close-Range Surveillance System (360° Situational Awareness System), Tank Laser Warning Receiver System (TLUS, to detect, classify, identify and give warning of laser threats aiming on the platform such as; Laser Range Finders, Laser Designators and Laser Beam Riders), Tank Driver Vision System (TDVS), Smoke Grenade Launchers, Air Conditioning System, Auxiliary Power Unit (APU) and Audible Warning System and Protective Coating (at the turret walls and ceiling, to maximize crew protection from possible shrapnel threats encountered in the event of RPG and ATGM attacks) on 169 M60T MBTs in the TLFC inventory. In April 2018 the SSB’s İsmail DEMİR announced with a tweet that under the FIRAT-M60T Modernization Project, delivery of the 90 40mm Automatic Grenade Launchers (AGL) had been completed. 40mm AGLs are integrated on SARP RCWSs and replaced the 12,7mm machine gun. Aselsan in cooperation with MKEK developed 40mm smart grenade munitions with airburst functionality and performed firing tests in April 2018. Some of the modernized M60Ts dubbed M60TM, were deployed during Operation Olive Branch that was launched on January 20, 2018 against YPG/PYD positions surrounding the Syrian city of Afrin.

With the Contract Amendment no 1, the total amount of the Project contract has reached EUR 206 Million + TL 50 Million. In accordance with the amendment to the contract, the AKKOR PULAT Active Protection System (APS) will be installed on 40 of the 169 M60TM MBTs tanks. Out of the 169 tanks named M60TM that were modernized as part of the FIRAT-M60T Project, the Telescopic Periscope System (TEPES) will be installed on 73 of these tanks. Moreover, 90 40mm automatic grenade launchers were procured in 2018 to be used in the tanks.

AKKOR PULAT APS is capable of physical destruction and it is able to simultaneously cope with multiple threats and it provides 360-degree protection capability. The system detects RPGs and ATGMS directed towards the M60TM AMT in the air with the help of the high technology radar it features and destroys them at an optimum distance before they hit the tank. Aselsan displayed the M60TM AMT equipped with the AKKOR PULAT APS in the outdoor exhibition area during IDEF ‘19. According to the information on the product’s brochure, the AKKOR PULAT APS contains three critical sub-systems: The Control Panel, Power Distribution Unit and the Counter Measure Module. Maximum 8 Counter Measure Modules that consists of a millimetre-wave Triggering Radar and Counter Measure Munition can be installed on every MBT. However, according to feedback given by the Turkish Armed Forces, and as no Counter Measure Module deployment was planned over the turret, only 6 Counter Measure Modules (2 on each of the sides, 1 on the front and 1 at the rear) exist on the M60TM. The system can be switched on and off with the help of the Control Panel in the driver’s cab and the Counter Measure Modules can be activated upon request only towards the direction of the threat while other Modules can be deactivated. When the module is activated, the Counter Measure Munition over it, in the form of a cylindrical stick, emerges out of its socket and remains outside the hull at a distance of 30-40cm. The sensor of the Triggering Radar remains on the tip of the cylindrical Counter Measure Munition. The Triggering Radar is able to scan up to 180 degrees in azimuth and 35 degrees in elevation and is said to be capable of detecting an approaching threat up to 50m and calculates its angle of approach. After the estimation of the optimum intercept point, when the threat is within the range the warhead right at the back of the millimetre-wave Triggering Radar is activated for interception. When the cylindrical Counter Measure Munition is activated it neutralizes the threat using a dense cloud of fast-moving splinters (small fragments scatter around in the shape of a ring due to the cylindrical form of the munition). The fast moving splinters directly shoots the warhead of the ATGM that constitutes a threat. After a physical impact either the warhead on the threat is disabled or the formation of the gel effect (in the HEAT type warhead) is prevented. According to Aselsan official as the fast-moving splinters moves 35 degrees upwards after the activation, it can, technically, also intercept ATGMs with a top attack capability to a certain extent. In one of his remarks, the former Minister of Defence Nurettin CANİKLİ stated that interception up to 8-10 meters was possible with AKKOR PULAT while with AKKOR APS interceptions up to a distance of 100 meters of could be conducted. In the field tests executed with AKKOR PULAT APS, over 400 ballistic tests were conducted against various threats such as RPG, Kornet-E, Konkurs and TOW.

With the help of the Telescopic Periscope System (TEPES) integrated on the M60TM AMTs, secure surveillance and target acquisition capabilities while in the defilade position are gained. On account of Aselsan’s TEPES mast mounted sighting system, which is to be integrated to a total of 73 M60TM AMTs, the tanks gain superior target acquisition and surveillance capabilities with high precision under all types of weather and geographical conditions. The capabilities of TEPES such as motion detection, target tracking, sectoral scanning, integrated operation with other systems (Laser Warning System, Remote Commanded Weapon System, etc.), acquisition of the target coordinates and video/ image recording will dramatically increase the survivability of the M60TM. The system capable of capturing thermal images and TV images via its E/O sensors is capable of conducting laser distance measuring up to 20 kilometers. TEPES can reach a height of 2.5 meters with the telescopic elevation system (mast) over the M60TM turret and is capable of calculating the coordinates of the target detected through INS integration and then submits them to the operator.

Roketsan and Aselsan have been selected for the modernization of M60A3 MBTs. With modernization undertaking, the aim is to increase the survivability, the firepower and the situational awareness of 40 M60A3 MBTs (sufficient to equip one tank battalion) in the Turkish Land Forces service. Dubbed the M60A3T1, the modernized M60A3 MBTs are integrated with a 12.7mm SARP RCWS, YAMGÖZ Close-Range Surveillance System (360° Situational Awareness System), Tank Laser Warning Receiver System (TLUS), Smoke Grenade Launchers, Tank Driver Vision System (TDVS), Fire Extinguishing – Explosion Suppression System, Audible Warning System, Power Distribution Unit, Protective Coating and Increased Armor Protection (Roketsan’s add-on ERA armor modules and slat armor at the rear of turret). M60A3T1 MBTs will be also integrated with Aselsan’s AKKOR PULAT APS. Photos of the modernized M60A3T1 MBTs were posted on social media/twitter accounts in March 2018.

BMC was selected for the modernization of 84 Leopard 2A4 MBTs (sufficient to equip two tank battalions/one brigade) under different categories and a contract (according to sources valued at around US$300 Million) was signed in 2017 between BMC and the SSB. But according to a BMC official, as a result of the constantly changing requirements of the end user the Project has evolved into a completely different point. Required modifications and evolutions to answer the TAF’s new requirements, that occurred during recently gained operational experiences, have been implemented on the Project structure and modernization efforts on prototype Leopard 2A4TM were launched in 2018. Modernization of the prototype Leopard 2A4TM is expected to be completed in 2019 and then Serial modernization of the remaining 83 MBTs will be initiated (either at the 1st Main Maintenance Factory Directorate or at the 2nd Main Maintenance Factory Directorate).

New Generation FIRTINA (FIRTINA-II) SPH

Serial production of the 140 New Generation T-155 FIRTINA (FIRTINA-II) Self Propelled Howitzers (SPH) commenced at the 1st Main Maintenance Factory Directorate in 2018. According to the Aselsan 2017 Activity Report, the first phase of Qualification Tests with the FIRTINA-II prototype were carried out in 2017. On December 14, 2018 Aselsan secured a contract valued at US$194,6 Million to deliver New Generation Fire Control Systems for the 140 FIRTINA-II SPHs that were ordered for the Turkish Land Forces Command.

Developed over the existing 281 FIRTINA-I SPHs, the FIRTINA-II SPH features some improvements over its predecessor including the new turret design with propellant conditioning unit, fully electrical and servo controlled turret & gun aiming and drive system (replacing a hydraulics based drive system), improved Fire Control System, increased firing rate, extended effective range, fully automatic ammunition loading system (FIRTINA-I is equipped with electrically driven and an electronically controlled automatic ammunition loading system) and integrated with Aselsan’s 12,7mm SARP RCWS for self-protection. The high degree of automation allows FIRTINA-II to react in a shorter timeframe to execute its mission, with reduced manpower. After receiving the fire command, FIRTINA-II is able to fire on target within 30 seconds, to complete the fire mission and to relocate in 90 seconds.

Operated by a crew of five, the 155/52 calibre T-155 FIRTINA-II SPH has a maximum firing rate of up to eight rounds per minute thanks to its automatic shell loading system. The maximum range of the 155/52-calibre gun is 18km with M107 (HE), 30km with M549A1 RAP (HE) and 40+km with MKEK/Roketsan MOD 274 HE ER ammunition. The FIRTINA-II SPH’s 52 calibre ordnance is capable to use all NATO standard ammunition. In order to meet the Turkish Army’s long range HE type artillery munitions requirement, MKEK in cooperation with Roketsan (responsible for the base bleed unit of the ammunition), developed MOD 274 HE extended range (ER) 15mm 52 calibre artillery ammunition and received a contract for the delivery of the first batch of 5,020 MOD 274 ammunitions at the end of 2014. In 2017 follow on orders for an additional 9,000 (2,000 + 7,000) MOD 274 HE artillery ammunition were awarded.

The T-155 FIRTINA-I and FIRTINA-II SPH prototypes are powered by German MTU-881 KA 500 1,000hp diesel engine coupled with Allison’s X1100-5 fully automatic transmission built in South Korea under Allison license. However, during IDEF ‘19 a MoU (Memorandum of Understanding) was signed between Caterpillar Defence UK and the Turkish MoND for the development of a new diesel engine, to be based on the core of Caterpillar Defence UK’s existing diesel engine but will be developed with the participation of 1st Main Maintenance Factory Directorate engineers to meet FIRTINA-II-specific requirements and it will be an ITAR Free product so as to not face any export license problems as in the case with MTU’s MTU-881 KA 500 engine. The development of a new V12 type 1,200hp diesel engine will take place at the 1st Main Maintenance Factory Directorate in Arifiye, Adapazarı. The new engine will be coupled with Allison’s X1100-5 fully automatic transmission because according to Caterpillar Defence UK officials the Turkish end user is happy with the existing transmission. Meanwhile, speaking at the Aselsan Union of Forces Summit held on February 5, 2019 at the ATO Congresium Center in Ankara, Turkish MoND Hulusi AKAR, formerly Chief of the Turkish General Staff, disclosed that Turkey has recently signed a contract with Qatar for the sale of FIRTINA Self Propelled Howitzers (SPHs). MoND AKAR did not share any figures regarding the number of FIRTINA SPHs to be delivered to the Qatar Emiri Armed Forces (QAAF). It is believed that the contract covers New Generation FIRTINA (also dubbed FIRTINA-II) SPHs, which are under production at the 1st Main Maintenance Factory Directorate located in the Sakarya province of northwest Turkey. In October 2018 it was reported that after receiving assurance that there would be no export restrictions, state-owned Machines and Chemical Industries Board (MKEK) signed a contract to procure 20 powerpacks (including 5TDFMA-1 engines) from UkrOboronProm (Ukrainian Government’s Defense Industry Enterprise) for the FIRTINA-II SPHs. Probably these 20 powerpacks would be installed in the QAAF’s FIRTINA-II SPHs.

Using same chassis and turret with the T-155 FIRTINA-I SPH, the POYRAZ Ammunition Resupply Vehicle is capable of loading ammunition in a supply area and transferring ammunition to the FIRTINA-I SPH within the required time and location in all kinds of terrains and battlefields. The POYRAZ Ammunition Resupply Vehicle has the necessary mobility and survivability capabilities for operation within the tactical operational environment of the FIRTINA-I SPH. Fitted with Aselsan’s automatic Ammunition Transfer System, and compatible with all kind of ammunition used for FIRTINA-I SPHs, the POYRAZ vehicle can carry 96 155mm projectiles and 96 modular powder charges. It can transfer 48 projectiles and 48 modular powder charges in less than 20 minutes to the FIRTINA-I SPH.

The Main Maintenance Factory Directorate completed production of the POYRAZ Ammunition Resupply Vehicle prototype in 2011 and the vehicle was displayed during the IDEF ‘11 Fair. Following the extensive test campaign acceptance of the prototype vehicle was completed and the serial production phase, covering 70 vehicles commenced in 2013. The 9.5m long, 3.76m height and 47 ton POYRAZ Ammunition Resupply Vehicle is operated by three crew and powered by a V-12 type 750hp AVDS-1790 diesel engine coupled with an Allison CD-850 automatic transmission. This power pack was obtained from M48A5T1 MBTs that were phased-out of Turkish Land Forces service.

KORKUT SPAAG and FNSS ACV-30

The KORKUT Self Propelled Anti-Aircraft Gun (SPAAG) System project covers the procurement of 42 Weapon System Vehicles (SSA, will replace existing aged M-42A1/A2 Duster Walker systems) and 14 Command and Control Vehicles (KKA) all based on the FNSS ACV-30 Armored Combat Vehicle (ACV) chassis. On June 25, 2011, Aselsan the Main Contractor of the KORKUT SPAAG System Program, awarded a Tracked Carrier Vehicle Development Contract to FNSS for the design, development and production of one Command and Control Vehicle chassis and two Weapon System Vehicle chassis prototypes to be based on the ACV-30 within two years.

After an extensive mobility and firing test campaign that was launched in 2015 and which was carried out with the participation of the SSB and Turkish Land Forces (TLF) representatives, acceptance of these vehicles was carried out on August 24, 2016 and the KORKUT SPAAG prototypes (2x Weapon System Vehicles and 1 Command & Control Vehicle) entered into the service of the TLF. The systems made a strong impression during the ‘Fire at Will 2017’ Operation on October 20, 2017 by achieving direct hits to targeted drones.

Following the successful completion of the prototype development and qualification phase, the KORKUT SPAAG Serial Production Phase, covering the production and delivery of 40 SSAs (Weapon Systems Vehicles) and 13 KKAs (Command and Control Vehicles) was launched with a contract valued at Euro 467,767 Million signed between the SSB and Aselsan in May 2016. Aselsan then signed a contract with FNSS to procure a total of 53 ACV-30 tracked vehicles. In accordance with the contract schedule, FNSS completed delivery of the first batch of ACV-30 chassis during the first half of 2018 to Aselsan, who then converted them into KKA and SSA configurations. Meanwhile MKEK, responsible for 35mm GDF-003 twin guns, completed the manufacture of the first batch of 6 guns to be installed on 3 KORKUT SSAs and carried out acceptance tests at the test range on April 26, 2018.

Delivery and acceptance of the first batch of 1 KORKUT KKA and 3 SSAs that were manufactured under the KORKUT SPAAG Serial Production Phase for the Turkish Land Forces Air Defence School and Training Center Command took place in March 2019. As part of the acceptance test, live firing was performed against a high-speed targeted drone flying at a speed of 200m/s. The second batch is scheduled to be delivered in September 2019. Serial Production and the delivery of 40 KORKUT SSAs and 13 KORKUT KKAs to the TLF will be completed by 2022. Each KORKUT SPAAG Team will consist of 1 KKA and 3 SSAs so that with 42 SSAs and 14 KKAs the Turkish Army will be able to establish 14 KORKUT SPAAG Teams.

The KORKUT SSA vehicle is equipped with an unmanned turret, which is armed with two 35mm Oerlikon GDF-003 automatic cannons produced in Turkey by MKEK. The vehicle has the capacity of carrying 400 35mm ammunitions in total, 200 of them (100 for each barrel) within a remotely operated unmanned turret, equipped with automatic ammunition loading system, and 200 of them within the chassis. The system is also equipped with the capability of firing 35mm ATOM air burst ammunition, similar to AHEAD, which is designed and developed by Aselsan in cooperation with TUBITAK-SAGE and produced by MKEK.

The crew includes a gunner, commander and driver who are seated in the chassis of the vehicle. The 35mm guns have a rate of fire of 1,100 rounds per minute. There is also a Ku-Band, 3D Fire Control Radar with a 30km instrumented range and is mounted on the rear top of the turret along with a thermal imager and a day TV camera on the right side. The KKA uses the same chassis, ACV-30, but is equipped with a turret including X-Band, 3D Mobile Search Radar (MAR), that provides fast and accurate detection and tracking of low altitude airborne targets up to a maximum range of 70km.

The ACV-30 platform chassis is provided with a unique, space laminated armor system combining steel and aluminum technology for protection against the firing of small arms and mine blasts. Powered by a 600hp diesel engine, coupled with fully automatic transmission, the 7,07m long, 3,62m overall height and 3,9m wide ACV-30 can reach 65km/h on the road and can swim at 6km/h with 2 water jets. Having a combat weight of 29,5 tons the ACV-30 has a cruising range of 500km.

ZAHA Program

On March 7, 2017 the Armored Amphibious Assault Vehicle (ZAHA/AAAV), also named the Marine Assault Vehicle (MAV) Program contract was signed between the SSB and FNSS. Under the contract the ZAHA will be developed and produced by FNSS based on an indigenous development model. FNSS will deliver a total of 27 vehicles, including 23 in personnel carrier, 2 in command and control vehicle and 2 in recovery vehicle configuration. The technical characteristics of the ZAHAs were determined by taking into consideration the operational concept and mission requirements defined by the Turkish Naval Forces Command.

FNSS revealed the first complete prototype of its Marine Assault Vehicle (MAV) at the IDEF ‘19 Fair held in Istanbul. According to FNSS CEO and General manager Nail KURT, MAV has entered the Critical Design Phase and the entire project is scheduled to be complete by 2021. According to FNSS, the MAV is built from 5000 series military grade aluminum armor, which is alloyed with magnesium. Alloys in the 5000 series are resistant to corrosion and relatively easy to weld, making them well suited for the construction of amphibious vehicles. The aluminum is used to form the structure of the hull as well as provide elements of the vehicle’s blast protection. The bottom of the hull is reinforced with support, and the thickness has been adjusted to maximize stiffness and energy absorption.

The MAV/ZAHA will be able to carry 21 fully equipped infantries as well as 3 crews, they will have ballistic and mine protection at a certain level and will be able to move rapidly in water and on land. They will have the capabilities of firing at targets with their unmanned turret with 12.7mm Machine Gun (MG) and 40mm Automatic Grenade Launcher (AGL) and perform operations at various sea levels.

Powered by a diesel engine, coupled with fully automatic transmission, the 8,3m long and 3,3m wide the MAV/ZAHA can swim at 7km/h with 2 water jets. With a combat weight of 30 tons the ZAHA will have a 21 troops capacity in addition to a three-man crew (driver, commander and gunner). To be integrated with a remotely operated turret armed with a 12,7mm machine gun and a 40mm automatic grenade launcher, the MAV/ZAHA can operate at sea state 4 conditions. The MAV/ZAHA will be able to negotiate up to 40% side slopes and a 60% gradient and is capable of crossing natural or man-made obstacles up to 90cm high, and trenches 2m wide.

Modern Medium Weight Tank (MMWT) Program

The Indonesian Modern Medium Weight Tank (MMWT) Program stands out as it is the first Government-to-Government (G2G) cooperation project in the Turkish Land Platforms Sector.

The conceptual design of the KAPLAN MT Harimau (Tiger) MMWT was completed and was revealed during the Indo Defence 2016 Fair held in Jakarta, Indonesia in November 2016. The first prototype developed and manufactured by FNSS in Ankara, Turkey underwent qualification trials in Indonesia, which was unveiled at the IDEF ‘17 Exhibition in Istanbul and also participated in the Army Day Parade in Indonesia on October 5, 2017. PT PINDAD engineers, who have been trained in the engineer¬ing development and manufacture phases of the first prototype at FNSS, also completed the production of the second prototype in Indonesia with support from FNSS. The qualification of the two MMWT prototypes as well as firing trials and durability tests were completed in 2018. KAPLAN MT is the first medium weight tank to be certified by the Indonesian Army and qualified for serial production. Following the successful completion of live firing tests and mobility trials FNSS and PT PINDAD initiated negoti¬ations towards the serial production of KAPLAN MT MMWT platforms, which the Indonesian Government indicates a keen interest in. During IDEF ‘19, where FNSS displayed the KAPLAN MT MMTW equipped with Aselsan’s AKKOR PULAT APS against increasing ATGM threats to tanks in the battlefield, on April 30, 2019 a Long-Term Contract on the Serial Production of KAPLAN MT (Harimau/Tiger) MMTW was signed between FNSS Savunma Sistemleri A.Ş. and PT Pindad. The contract covers the procurement and delivery of 18 KAPLAN MT Harimau MMWTs to the Indonesian Land Forces within two years.

Based on the FNSS KAPLAN-30 chassis and dubbed the Harimau (Tiger) by Indonesia, MMWT design comprises advanced ballistic and mine protection with a broad range of firepower, from close support of infantry to anti-armor. The KAPLAN MT Harimau MMWT is fitted with CMI’s Cockerill 3105 (CT-CV 105HP) turret armed with a 105mm L-53 CV rifled gun and a coaxial 7,62mm machine gun and for ease of deployment in jungles/tropical forests and the soft grounds of Indonesia, the vehicle has a combat weight of 35 tons. Since the main gun uses an autoloader (with 12 rounds ready to fire) the KAPLAN MT Harimau MMWT has a three-man crew. The 7m long and 3.2m wide and 2.7m height KAPLAN MT Harimau MMWT has a top speed of 70km/h on roads and a cruising range of 450km, with on-board fuel. In order to have a minimum power to weight ratio of 20hp/tons, the KAPLAN MT Harimau MMWT is believed to be powered by a 700hp class power pack.

PARS-II/AV-8 Gempita ACV Program

Under the US$559 Million contract awarded in February 2011, in cooperation with DRB-HICoM DEFTECH of Malaysia FNSS will design, develop and produce a total of 257 armored personnel carriers to be based on PARS-II 8x8 in 12 different configurations including; the infantry fighting vehicle (IFV), armored fighting vehicle (AFV), the armored personnel carrier (APC), tank destroyer (AFV-ATGW), command vehicles (ACV), signals (AVS), reconnaissance vehicle as well as recovery vehicle. While the original PARS 8x8 was 24-25 ton vehicle, the AV-8 IFV-25 configuration weighs 28 tons and its equipment differs considerably from that of PARS. Deliveries will span over 7 years and are planned to be completed by 2020. Malaysia is said to be considering placing an order for the second and third batches of AV-8 vehicles. The second batch is expected to be on the agenda around 2021-2022.

On December 6, 2014 the Malaysian Army received delivery of the first 12 of 257 AV-8 Gempita Armored Combat Vehicles (ACVs). The then Malaysian Army Chief General Raja Mohamed Affandi Bin Raja Mohamed NOOR accepted the first batch of 12 vehicles, all of which are in the IFV-25 configuration. During a ceremony witnessed by the then Prime Minister Najib Tun RAZAK, formally named the vehicle ‘the Gempita’, which is a Malay term for ‘thunderous noise’. The IFV-25 configuration of the AV-8 ACV is fitted with a one-person FNSS Sharpshooter turret armed with a stabilized ATK Armament Systems M242 25 mm dual-feed gun and an FN MAG 58M 7,62 mm co-axial machine gun. 46 of the 257 AV-8 vehicles will be delivered in IFV-25 configuration. The weapons systems capabilities of the AV-8 Gempita includes; a 25mm gun, specially designed two-man turret with a 30mm gun, 12.7mm RCWS as well as an Anti-Tank Guided Weapon (ATGW).

RAO PARS-III 8x8/6x6 WAV Program

During the second half of 2015, FNSS received a contract valued at around US$ 500 Million from the Royal Army of Oman (RAO) and the Ministry of Defence of the Government of the Sultanate of Oman to design, develop, manufacture, qualify (both international and customer) and deliver a total of 172 PARS-III Wheeled Armored Vehicles (WAVs) in 13 configurations and the contract became effective on September 20, 2015. Under the contract FNSS will deliver 145 PARS-III 8x8 vehicles in 8 different configurations and 27 PARS-III 6x6 vehicles in 5 different configurations. Contract period will be finished in May 2020. This contract represents the second export order for the PARS WAV following Malaysia. RAO PARS-III 8x8WAVs feature some country specific modifications and upgrades and have slightly different appearance compared to PARS-II/AV-8 Gempita vehicles of the Malaysian Army. Contrary to PARS-II/AV-8 vehicles, the RAO PARS-III WAVs do not have swimming capability but in return they have better ballistic and mine/IED protection thanks to add-on armor modules. The official delivery of the first PARS-III WAV to the RAO took place on July 12, 2017 at the FNSS facilities located in Gölbaşı, Ankara/Turkey.

The PARS-III 8x8 is powered by a German Deutz turbocharged, water-cooled diesel engine, developing 550hp coupled to a fully automatic transmission with 7 forward and 1 reverse gear. Meanwhile, the power pack of the PARS III 6x6 consists of a water-cooled turbocharged diesel engine with an output power of 483hp and a fully automatic transmission with 7 forward and 1 reverse gears. The diesel power pack is mounted to the rear of the driver on the left side of the hull, between the first and second axles. The power pack architecture, which allows disassembly and reassembly in less than 60 minutes, allows the user to replace the engine in the field as an additional benefit.

RABDAN 8x8 AACV

In February 2017, during the IDEX 2017 Fair, Otokar signed a deal worth US$661 Million to build 400 ‘RABDAN’ 8x8 Amphibious Infantry Fighting Vehicles (IFVs, based on ARMA 8x8 and fitted with a Russian-made two-man turret armed with a 100 mm 2A70 gun, a 30 mm 2A72 coaxial cannon and a 7.62 mm PKT coaxial machine gun) for the United Arab Emirates (UAE) Land Forces. The ‘RABDAN’ 8x8 Amphibious IFVs will be manufactured both at Otokar facilities in Turkey and by Al-Jasoor, a Joint Venture company between Otokar LS and Heavy Vehicles Industries of Tawazun at the Tawazun Industrial Park manufacturing facilities in Abu Dhabi. According to the contract signed in February 2017, the production of the first 100 vehicles will be accomplished at Otokar’s facilities. To this end, Otokar started the delivery of the RABDAN IFVs to the UAE Land Forces in the last quarter of 2018 (October/November). In this context the first RABDAN armored vehicles out of production successfully completed acceptance tests at the Otokar plant in Sakarya as well as amphibious and firing tests in the Gulf, and the first batch was delivered to the UAE. Following the delivery of the first batch of RABDAN IFVs late last year, the vehicles were included in the inventory of the UAE Armed Forces. As of February 2019, a total of 30 vehicles were delivered, and this number is expected to reach 120 by the end of 2019. According to the contract, the first 100 vehicles would be built at the Otokar plant in Sakarya and the remaining vehicles will be built at the Tawazun Industrial Park facility in Abu Dhabi. In this context, Otokar started the mass production of RABDAN vehicles in 2017. Due to the urgent need of the UAE Land Forces, deliveries are being carried out 4-5 months ahead of the schedule specified in the contract. In this context, a workshop was established by Otokar/Al Jasoor in the UAE for the final assembly of vehicles. Otokar/Al Jasoor has also started training activities for the crew (driver, vehicle commander, gunner) and maintenance personnel of RABDAN IFVs in the UAE. In this context, delivery of the training support equipment was completed in early February. Otokar also is conducting negotiations with UAE for the second phase that covers the delivery of further 300 vehicles in various configurations. According to sources, the UAE Army also has a plan to order a further 500 RABDAN IFVs under the third phase of the project.

According to the first technical specifications released by the UAE Company Al Jasoor Heavy Vehicles Industries, the RABDAN has the capacity to carry a total 12 personnel including driver and commander. It has gross vehicle weight (GVW) from 28,000 kg to 30,000 kg. The RABDAN is powered with a Caterpillar 12,5 liter diesel engine developing 600hp coupled to an Allison 4500 automatic transmission with 6 forward and 1 reverse gear. The RABDAN has a top speed of 105km/h and a cruising range of 700km. The RABDAN offers ballistic protection up to STANAG Level 4 and mine protection up to STANAG Level 4a/b. The vehicle is fully amphibious and propelled in the water at a maximum speed of 10km/h thanks to two propellers mounted under the hull rear. The 8x8 vehicle is fitted with a two-man BMP-3 turret, which is armed with one 100mm 2A70 semi-automatic rifled gun/missile launcher as the main armament and one 30mm 2A72 coaxial cannon and one 7,62mm PKT coaxial machine gun as the second armament.

AKREP-IIe Electrical Armored Vehicle

Designed and developed by Otokar as an armored reconnaissance and weapons platform, the AKREP-IIe 4x4 New Generation Armored Vehicle Product Group is manufactured to fulfil the contemporary and future demands of armies with its low silhouette. In addition to its operational performance under all types of field conditions the vehicle has high maneuver capability and has an infrastructure that enables the utilization of alternative power packs such as electricity, diesel and hybrid. The power generation and transmission systems, sensors, computers, communication and targeting systems are integrated within a single system in the AKREP-IIe and the vehicle provides an infrastructure that will accelerate the transition to autonomous vehicles. Different configurations of the AKREP-IIe were designed, such as the Armored Reconnaissance Vehicle, Fire Support Vehicle (90mm gun), Light Weight Infantry Support Vehicle (25mm gun, the model displayed at the Fair) and Laser Gun Vehicle. Two NMC540 Serial new generation Li-Ion battery packs manufactured by Altınay Company were included in the Light -Weight Infantry Support Vehicle with a hybrid propulsion system were displayed at the Fair. The product AxleTech an independent suspension system is also present in the vehicle. The AKREP-II Fire Support Vehicle to be equipped with a 360hp power capacity diesel engine and CMI Cockerill CSE90LP 90mm automatic gun is expected to be revealed at the EuroSatory 2020 Fair.

The AKREP-IIe in surveillance and force recon/combat reconnaissance configuration has a crew of three; Driver, Gunner and Commander. However, all the main functions of this vehicle can be implemented by a crew of two. The Driver sits in the center of the vehicle upfront and has access to a modern, sports car like, re-programmable three large flat-panel multi-function displays. Commander (left) and Gunner (right) sits behind the Driver and can control sensors, radios and the 25mm gun the AKREP-IIe is carrying. Both Commander and Gunner have a large multi-function display and the Gunner can control the 25mm remotely operated gun via control stick with multi-function buttons. Vehicle is also fitted with a mast-mounted long-range day/night observation system with 360-degree surveillance capability.