Turkish Industry Takes Off in Support of F-35

Istanbul, Turkey // May 08, 2013

Murad Bayar, Turkish Undersecretary for Defense Industries, and Steve O’Bryan, Lockheed Martin F-35 VP, Program Integration, stand together after an Industry Participation ceremony at IDEF 2013 in Istanbul, Turkey, May 8. Undersecretary Bayar expressed his support for the F-35 program and the Turkish Industry which could realize more than $12 billion of business over the life of the program.

Ten Turkish companies participated in the Lockheed Martin F-35 Industry Recognition Event during the IDEF tradeshow today. Turkish companies are major contributors to the current international production of the F-35 Lightning II and the advanced Turkish SOM weapon in development to be used on the F-35 and have resulted in approximately 1,000 jobs for Turkish industry. Murad Bayar, Undersecretary for Defense Industries (SSM), was recognized for the role SSM provides in the form of leadership, vision, and the commitment of Turkish industry as a best value contributor on the F-35 Program.

“Lockheed Martin values the partnership we have established with the Turkish government, military and industry during the past quarter century with the F-16 and the C-130,” said Steve O’Bryan, vice president, F-35 Program Integration and Business Development, Lockheed Martin Aeronautics. “That relationship continues to flourish as every F-35 delivered has Turkish components.”

The 10 Turkish companies supporting the development production of F-35 include:

-

Alp Aviation has been supporting the program since 2004 and currently manufactures F-35 production airframe structure and assemblies, production landing gear components and production F135 engine titanium integrated blade rotors for the engine.

-

Aselsan is developing manufacturing approaches for advanced optical components, which are part of the F-35 Electro Optical Targeting System. They are also working with Northrop Grumman on the F-35 CNI Avionic Interface Controller and will initiate full scale production activities in the near term.

-

Ayesas currently is the sole source supplier for two major F-35 components – missile remote interface unit and the panoramic cockpit display.

-

Fokker Elmo manufactures 40 percent of the F-35 Electrical Wiring & Interconnection System (EWIS) and will also deliver and support TAI with all center section wiring systems. Fokker Elmo will also develop the EWIS for the engine, for which a major share is produced in Fokker Elmo Turkey in Izmir.

-

Havelsan has been supporting the F-35 training systems since 2005. Additionally, Havelsan has been instrumental as the Turkish lead for developing the construct of the future Turkish F-35 Integrated Pilot and Maintenance Training Center (ITC) and associated training systems in Turkey.

-

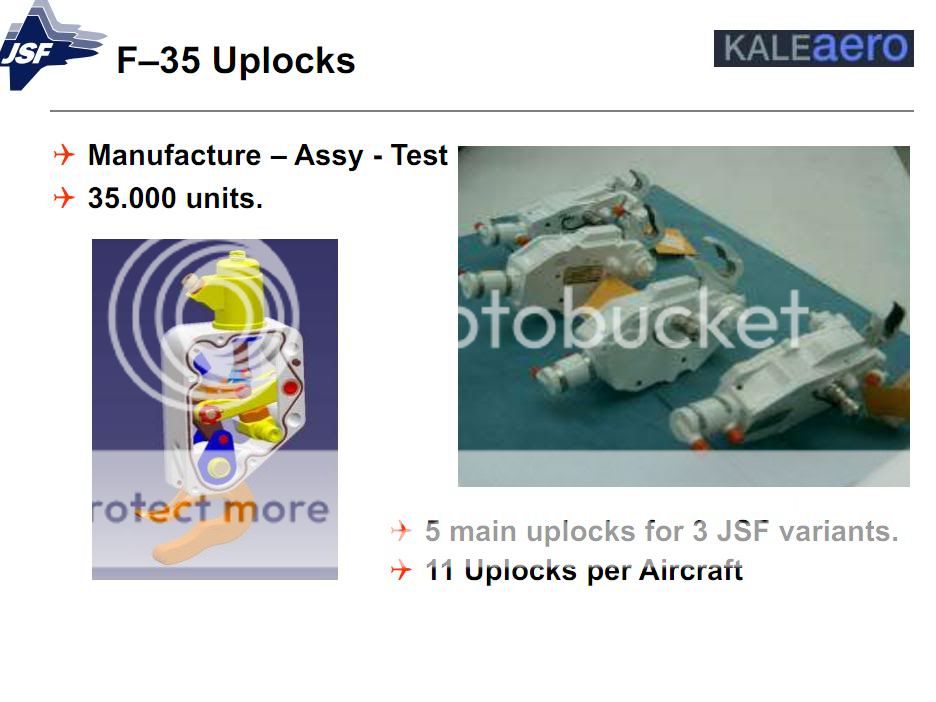

Kale Aerospace has been supporting the F-35 since 2005. In conjunction with Turkish Aerospace Industries, they manufacture and produce F-35 airframe structures and assemblies. Kale Aero also supports Heroux Devtek as the sole source supplier for all three variants landing gear lock assemblies. Additionally, Kale Aerospace has also established a joint venture in Izmir with Pratt & Whitney to manufacture production hardware for the engine.

-

MiKES has been supporting the F-35 Program since 2004 and MiKES has delivered F-35 aircraft components and assemblies for British Aerospace Engineering (BAE) and Northrop Grumman.

-

ROKETSAN and Tubitak-SAGE are the Turkish joint leadership team who strategically manage the development, integration, and production of the advanced precision-guided Stand-off Missle (SOM) which will be carried internally on the 5th Generation F-35 aircraft.

-

Turkish Aerospace Industries (TAI) has been strategically supporting the F-35 Program since 2008. Currently supplying production hardware that goes into every F-35 production aircraft. In conjuction of Northrup Grumman, TAI manufactures and assembles the center fuselages, produces composite skins and weapon bay doors, and manufactures fiber placement composite air inlet ducts. Additionally, TAI is strategically manufacturing almost 50 percent of F-35’ Alternate Mission Equipment (AME) including Air-to-Ground Pylons and adapters. In 2011, TAI and Pratt & Whitney signed a strategic agreement to pursue options for future F135 FACO and MRO capabilities for Turkey. TAI who has also been assigned to represent the organic depots of the Turkish Armed Forces within the Autonomic Logistic Global Sustainment (ALGS) system.

The F-35 Lightning II is a 5th generation fighter, combining advanced stealth with fighter speed and agility, fully fused sensor information, network-enabled operations and advanced sustainment. Three distinct variants of the F-35 will replace the A-10 and F-16 for the U.S. Air Force, the F/A-18 for the U.S. Navy, the F/A-18 and AV-B Harrier for the U.S. Marine Corps, and a variety of fighters for at least ten other countries.

Headquartered in Bethesda, Md., Lockheed Martin is a global security and aerospace company that employs about 118,000 people worldwide and is principally engaged in the research, design, development, manufacture, integration, and sustainment of advanced technology systems, products, and services. The Corporation’s net sales for 2012 were $47.2 billion.

Lockheed Martin