3D printing reshapes manufacturing

Updated: 2013-02-18 08:02

By Wang Ying in Shanghai ( China Daily)

Tulip table lamps, made by Materialise NV, a Belgium-based company focusing on 3D printing services, on show in Shanghai. A report on the development of 3D printing is expected to receive the central government's green light and funding support, a move that will encourage more small and medium-sized companies to enter the promising industry. Provided to China Daily

New technology may herald a third industrial revolution, say supporters

In Jackie Chan's latest movie CZ12, also known as Chinese Zodiac, there is an eye-catching scene in which the actor uses specially made gloves to scan a bronze animal head that once crowned the famed fountain clock of the imperial retreat Yuanmingyuan Park (the Old Summer Palace). The action star then recreates the bronze head using a printing machine that operates three-dimensionally.

Although the scenario is fictional, three-dimensioned printing technology now exists and will be widely applied in many industries soon.

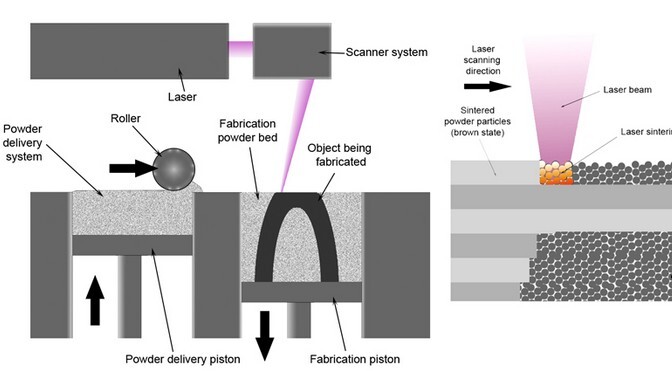

With modern technology, it is possible to print anything drawn on paper as three-dimensional objects. Researchers and scientists call it "additive manufacturing" but it is better known as 3D printing.

In mid-October last year, the Chinese Academy of Engineering launched research into the prospects for additive manufacturing. Many industrial experts participating in the survey will complete their first drafts in March. Final versions are expected to be submitted to the State Council by June, some involved in the survey told China Daily.

It is expected the report will receive the government's green light and funding support, which will encourage more small and medium-sized companies to enter this promising industry.

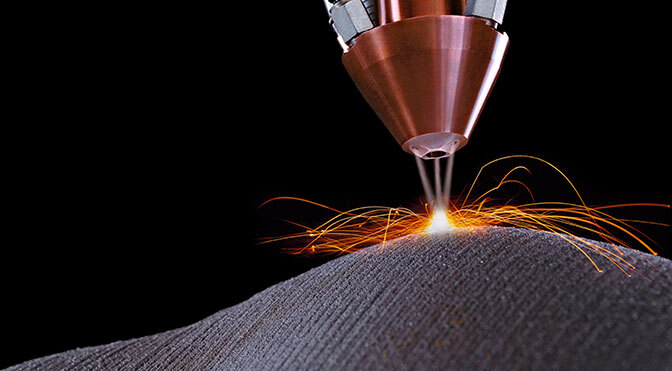

The early development of 3D printing can be traced back to the 1980s and its inventor, Chuck Hull, the US co-founder, executive vice-president and chief technology officer of 3D Systems. A few years later Chinese experts started to explore this area. Unlike traditional manufacturing based on the removal of material by cutting and drilling, 3D printing creates objects by adding layers from materials such as wax, metal and polyurethane according to virtual blueprints from computer-aided designs.

Experts are divided on the technology's future, with some asserting 3D printing will lead to a third industrial revolution.

"3D printing technology will profoundly change the traditional design and manufacturing models. So long as you have a draft, we can print anything you want according to it," said Shi Yusheng, a professor at Huazhong University of Science and Technology.

"In 1999, we printed the shell for a computer mouse using polystyrene. That was a really exciting moment," said Shi.

According to Wim Michiels, executive vice-president at Materialise NV, a Belgium-based company focusing on 3D printing services, over the past few years an increasing number of materials have been tested and put into use in 3D printing.

"This will mean a third industrial revolution, since localized production can be carried out on demand according to the requests of the customer. The customer will be less dependent on low-cost countries setting up production lines. We particularly see a lot of potential in the medical field, where customization is something that is opening doors for patients, doctors and researchers," Michiels said

However, Lin Feng, deputy director of the mechanical and engineering department at Tsinghua University, regards the new technology more as a supplement to traditional manufacturing.

"In cases in which only a couple of pieces are needed for a finished product, the advent of 3D printing will be highly efficient and economical compared with traditional manufacturing, which requires making the mold first and then starting mass production several months later. With 3D technology, the same product can be produced immediately," said Lin.

"It may be more appropriate to call it renovation rather than revolution," said Lu Bingheng, head of the mechanical and engineering department at Xi'an Jiaotong University.

Modern manufacturing features mass production and standardization but it has faced an increasing challenge to satisfy more individual requirements from clients since the start of the 21st century. Therefore, demand for tailor-made products makes 3D printing possible, said Lu.

"Three years ago, we spent about 1 million yuan ($160,000) in developing two models to make the outer shell of a car within three months. Similar development using traditional methods requires more than one year and will cost tens of millions of yuan from making the initial model to manufacturing in bulk," said Lu.

However, Lu also noted such production cannot completely replace traditional manufacturing, especially for products that need to be made in large amounts and feature a high degree of similarity.

In the eyes of Wim Michiels, executive vice-president at Materialise NV, 3D printing is better for the environment in that there is no need to set up a full production line, which can involve a lengthy amount of time, high costs and the possible failure of the first sample due to imperfect accuracy.

"3D printing is faster and you can bring your products to the market ahead of your rivals. In addition, you have no limitations in design with this technology," Michiels said.

Although theoretically 3D printing technology can print anything from a house to a car, it needs time to test the products before they can become practical in daily life, said Lin of Tsinghua University.

"After more than a decade's research into 3D printing, people are gradually beginning to accept this new manufacturing concept. Of the two main opposing opinions, one has doubts about the production technology while the other has excessively high expectations," said Lu of Xi'an Jiaotong University.

He added that both opinions are biased. "3D printing technology is consistently improving. It just needs more research and development to make it possible to print objects using various materials. It is also worth noting there is no technology that can do absolutely anything," Lu said.

Many Chinese enterprises are keeping a close eye on the market potential for 3D printing and have started to develop their own printers. Beijing Tiertime Technology Co is one such example. The company has so far sold several thousand sets to the United States, but only several hundreds in the Chinese market.

"Our company has nearly 20 years of history. Our products for home use are priced at 9,999 yuan, while those for industrial applications are sold at 100,000 to 300,000 yuan a set," said Lin Yuting, an employee with Tiertime's marketing department.

Tiertime's Lin said most of their orders come from overseas markets including Europe and the US.

Admitting there is a gap in the application of 3D printing between China and abroad, Shi of Huazhong University of Science and Technology said the technology is widely used in product development in overseas markets including aerospace, medical treatment, innovation and education. Shi added there was little progress in such applications in China.

In terms of applications, the US accounts for 40 percent of the global market while China has less than 6 percent, said Xi'an Jiaotong University's Lu.

Experts say it has a lot to do with the lack of innovative design in China. "Most of the mass-produced products in China do not have a copyright so manufacturers just copy the models and make more of them," said Lu.

Lu said many manufacturing enterprises are plagued by overcapacity. One solution is to put more focus on developing innovative products.

"We see a growing trend in China toward additive manufacturing where, initially, applications in the medical field will benefit and be used. Furthermore, an increasing number of industrial research and development centers are moving to China. They will also start to make use of 3D printing," said Kim Francois, managing director of Materialise China.

Francois said she saw an unlimited amount of possibilities in the Chinese market but it will take some time until they will be fully developed and integrated into society (something that is still ongoing in the US and Europe).

Additive manufacturing turned out products valued at $1.7 billion in 2011. The industry is growing at an annual rate of up to 30 percent. It is estimated the industry will be valued at $6 billion by 2020, with China accounting for between 15 percent and 20 percent of it by then.

"This size of industry cannot be called large but, if more enterprises from various industries embrace 3D printing, there will be huge capacity to work on it," said Lu.

Lin from Tsinghua University said his team is working on developing 3D cell structure printing at the moment.

"The characteristics of a cell have a lot to do with its shape. If we can imitate the cell and tissue activity in the human body, we can research how human beings work and even the processes of diseases. We can then use these research results to select medicines and even to study cancerous cells, a major cause of serious disease in human beings," said Lin.

Lu, from Xi'an Jiaotong University, has a more ideal outlook regarding the future of 3D printing.

He and his team are currently trying to bring down the cost of 3D printers. He said within one year they will be able to lower the price by several thousand yuan.

"By doing this it will become possible for such facilities to be used by middle schools and even domestically. Cultivating creative and innovative thought among the young will mean a lot for the nation's future," Lu said.