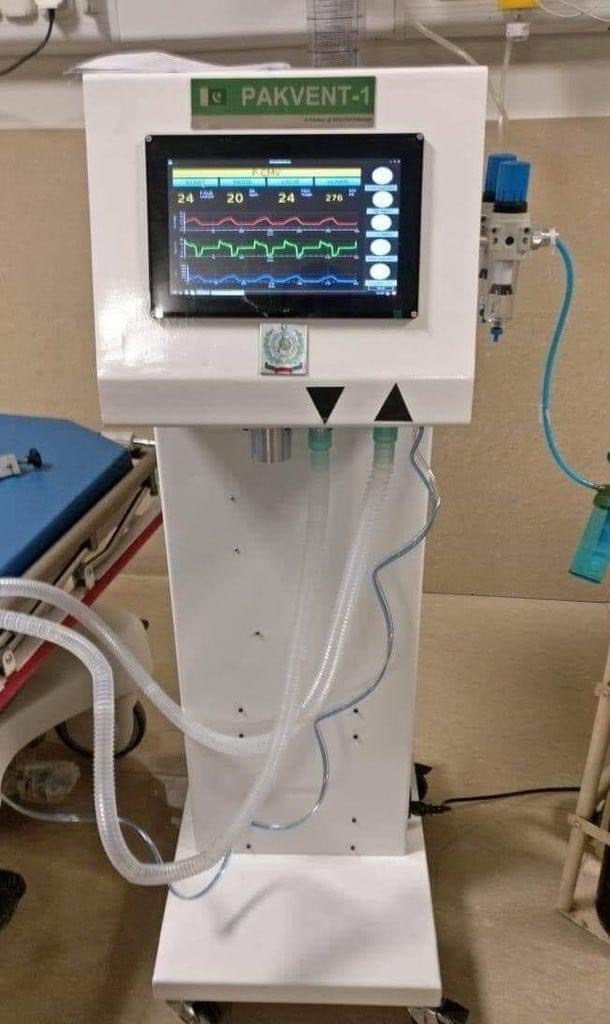

They were something like 50 ventilators designs submitted to Pakistan Engineering Council. 3 have been approved and are in clinical trials and Drug Regulatory Authority Pakistan's approval is awaited, pending the trial results.

The last step is commercial production and the ministry is getting the designers in touch with large industrial concerns. POF won't have a problem in this last step.

I hope the Army has learnt that reliance on foreigners for medical devices is as dangerous to the country as reliance on weapons. We need to make as much as possible locally. Create jobs, export opportunities in addition to not having to run to the four corners of the world trying to secure ventilators.