How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Modified Stealth Helicopter in OBL raid

- Thread starter Manticore

- Start date

Manticore

RETIRED MOD

- Joined

- Jan 18, 2009

- Messages

- 10,115

- Reaction score

- 114

- Country

- Location

nightcrawler

FULL MEMBER

- Joined

- Sep 10, 2008

- Messages

- 1,400

- Reaction score

- 0

I think it would be more likely that the US probably hacked the Pakistani air defence system through a back door they put in themselves and used that the same way the Israelis used a French backdoor to the Syrian air defence network a few years back.

Rather than take out the system they simply turned radar antenna away from the flight path at the right time to let the aircraft in and out without being seen.

Makes rather more sense to me.

Rather than take out the system they simply turned radar antenna away from the flight path at the right time to let the aircraft in and out without being seen.

Makes rather more sense to me.

Manticore

RETIRED MOD

- Joined

- Jan 18, 2009

- Messages

- 10,115

- Reaction score

- 114

- Country

- Location

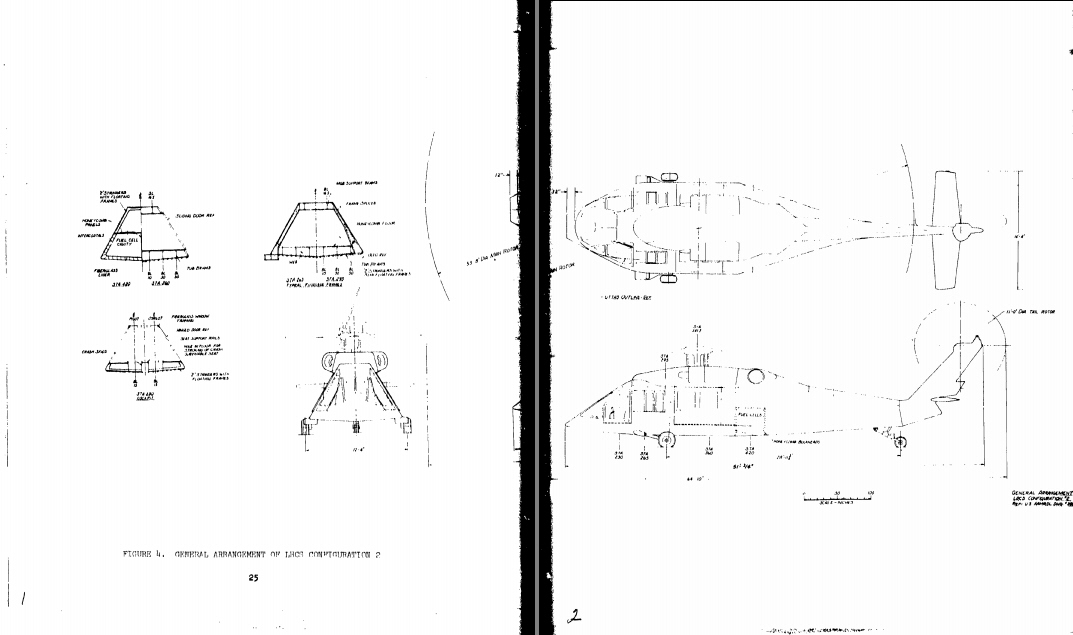

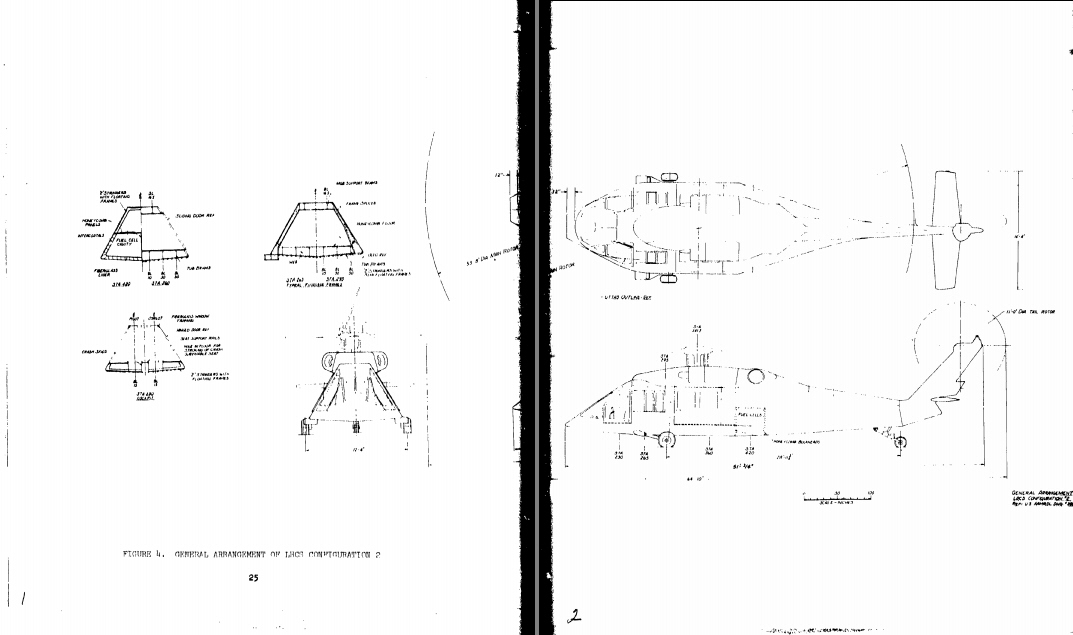

config2

3

1

Stealth Black Hawk updated rendering: 1978 document suggests a different shape for the modified UH-60 « David Cenciotti's weblog

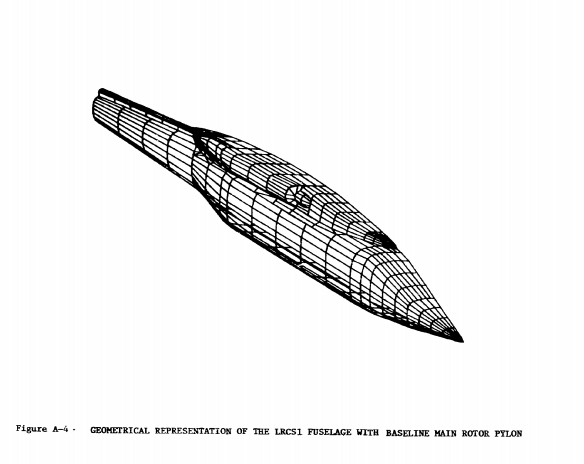

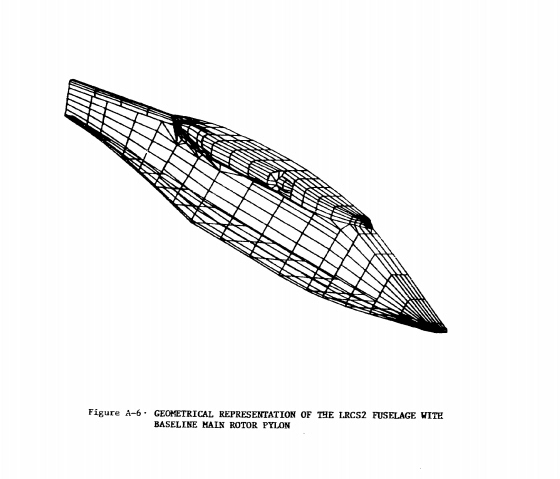

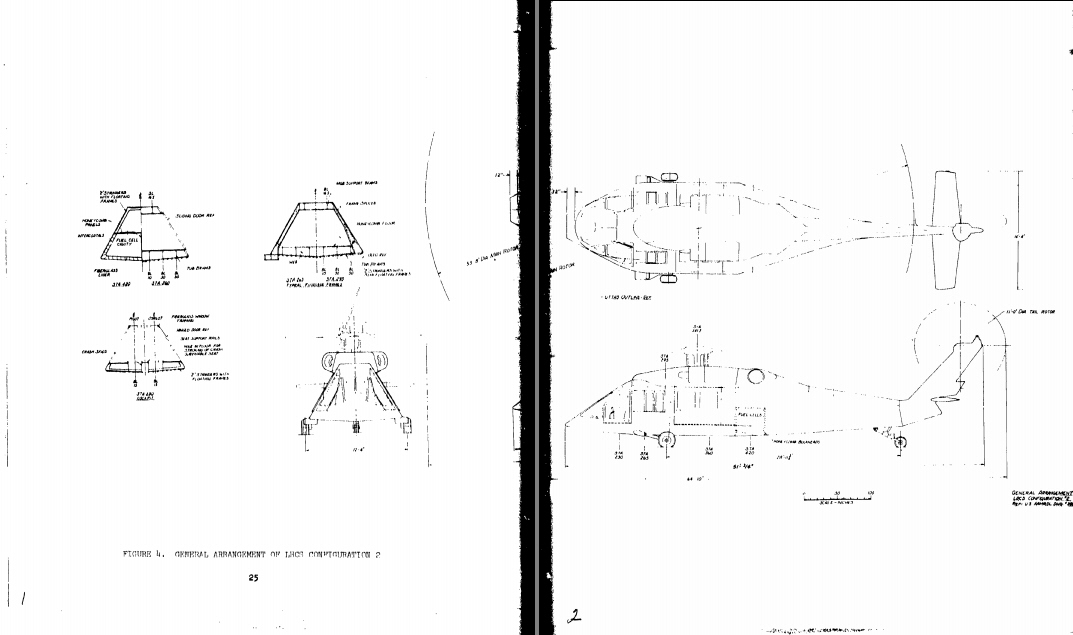

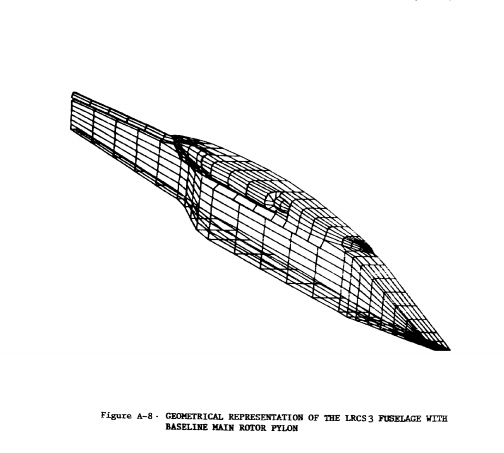

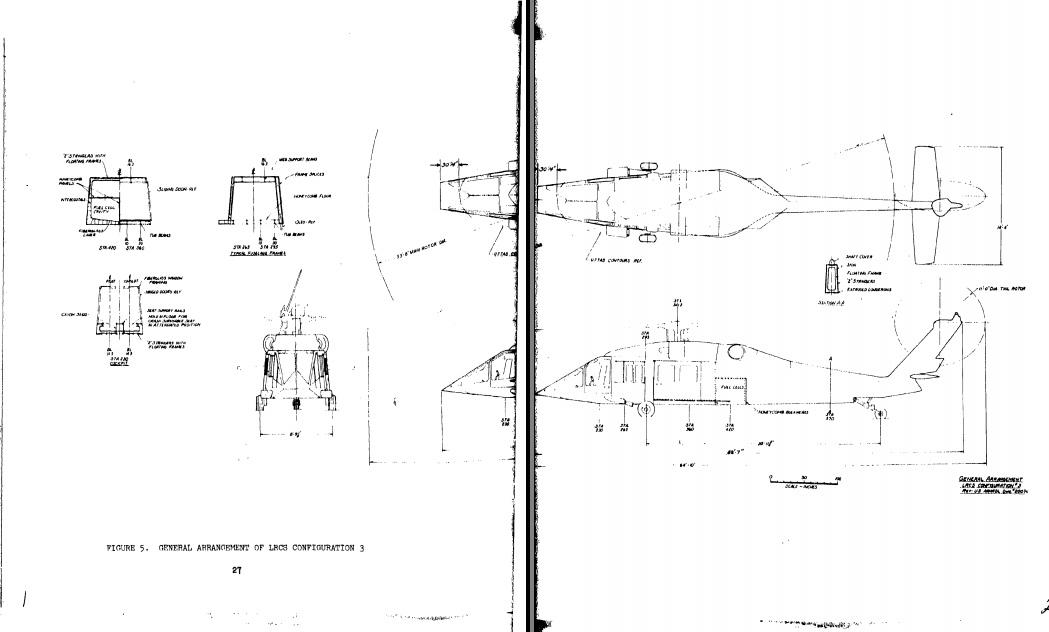

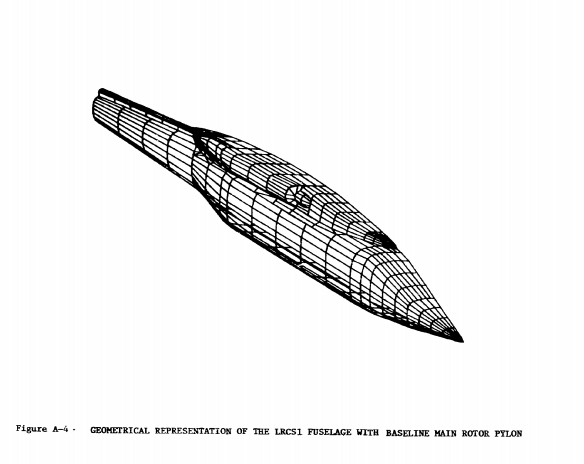

Three fuselage configurations for low radar cross sections were developed by the Applied Technology Laboratory. [...] The main rotor pylon fairings and tail surfaces aft of a tail fold hinge for each configuration were the same as those for the baseline UH60A. In the initial portion of this study, the weight and costs (percent of total) were developed for sections of the baseline UH60A fuselage. [...] Structural concepts were developed which could be applied to each configuration using conventional materials. An assessment of safety, fail-safety, and maintainability for each configuration was performed. The change in structural weight and the percentage change in cost for each configuration using the concepts developed were compared to those of the baseline. One concept was selected and applied to the three configurations.

Having selected the structural concept with the lowest weight change and percentage cost change for the three fuselage configurations, the effect on weight and costs using advanced materials was developed and applied to the three configurations. To evaluate the impact of the results of the fuselage study, design attributes of six helicopters were developed using a Helicopter Design Model (HDM) computer program.

Three low radar cross section fuselage configurations for this study were developed by the Applied Technology Laboratory. The first configuration slightly modified the nose section from the baseline configuration; the second configuration changed the fuselage shape along the lines of a truncated triangular prism; the third extended canted flat side shaping throughout the fuselage. The tail surfaces and main rotor pylon fairing were the same as those of the baseline UH60A.

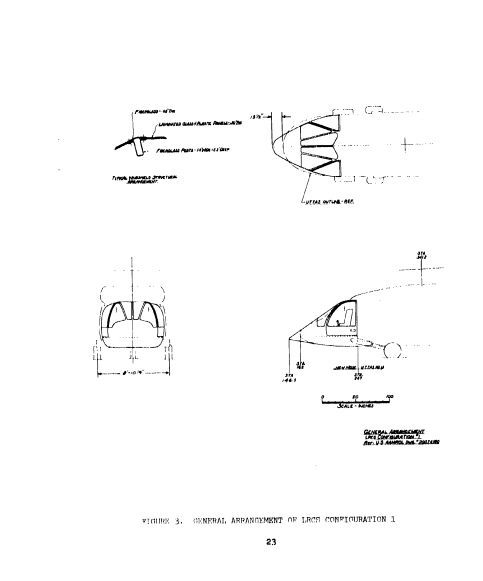

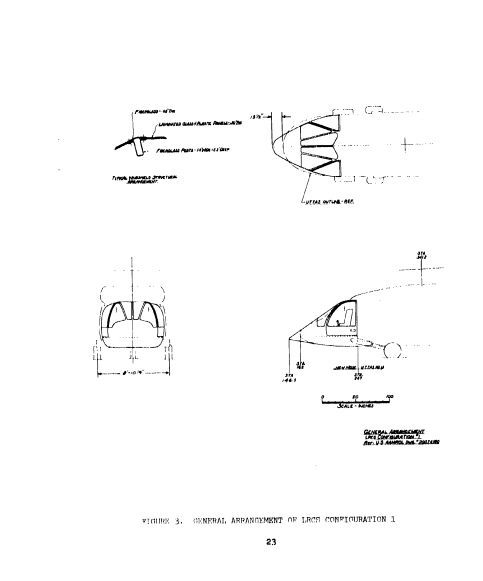

CONFIGURATION 1

This configuration alters the baseline fuselage forward of the mid-cabin section (the cockpit). Although this configuration is different from the baseline, the internal structure must be compatible with the forward cabin to avoid a heavy joining structure. The overall length is slightly increased due to this configuration.

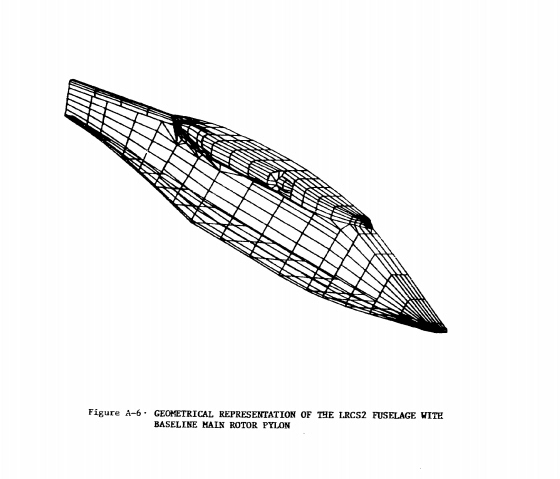

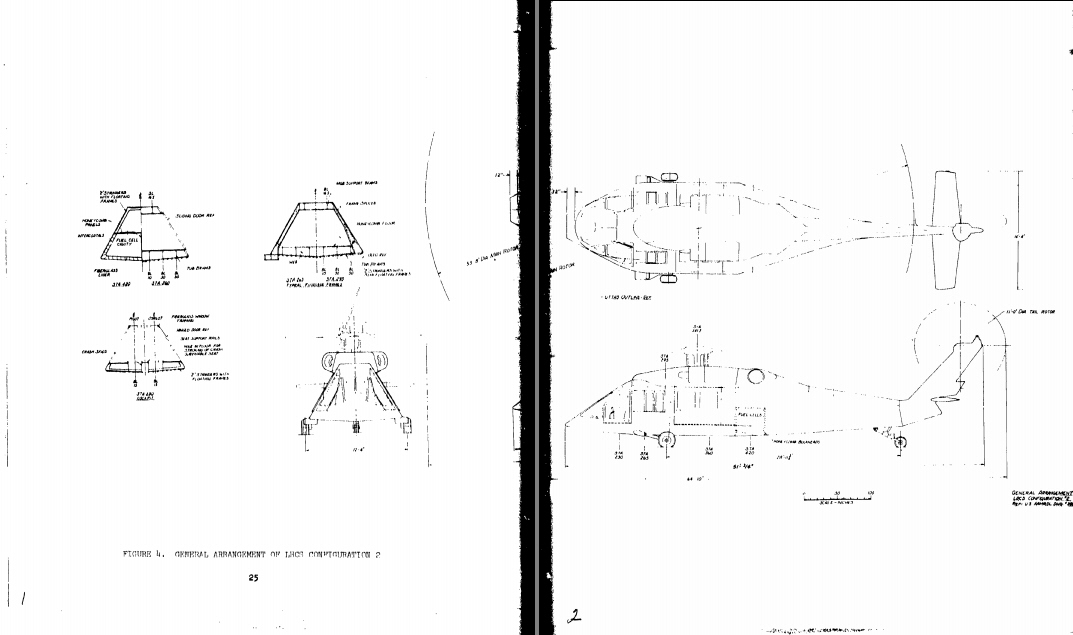

CONFIGURATION 2

This configuration is basically a trapezoidal cross section airframe having sides canted inward 30° and made up of flat exterior structural panels. This configuration is wider at the bottom of the fuselage and narrower at the top of the fuselage than the baseline. This configuration is slightly longer than the baseline UH60A, and its overall height is slightly larger than the baseline. The increased length, width, and height of Configuration 2 does not allow an aircraft of this size to meet the air transportability requirements of the baseline. The narrow upper fuselage causes the pilot and copilot seats to be spaced closer to each other, and shoulder room in the main cabin is decreased. The main cabin floor is approximately 6 inches higher than the baseline from the ground. The increased floor-to-ground height causes difficulties for combat troops to enter or leave the aircraft quickly. Minor modifications of the mold lines for the transition and tail-cone sections were made to properly house the tail rotor shaft of the baseline UH60A.

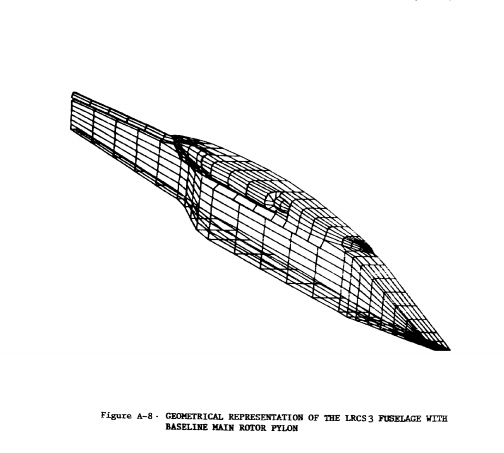

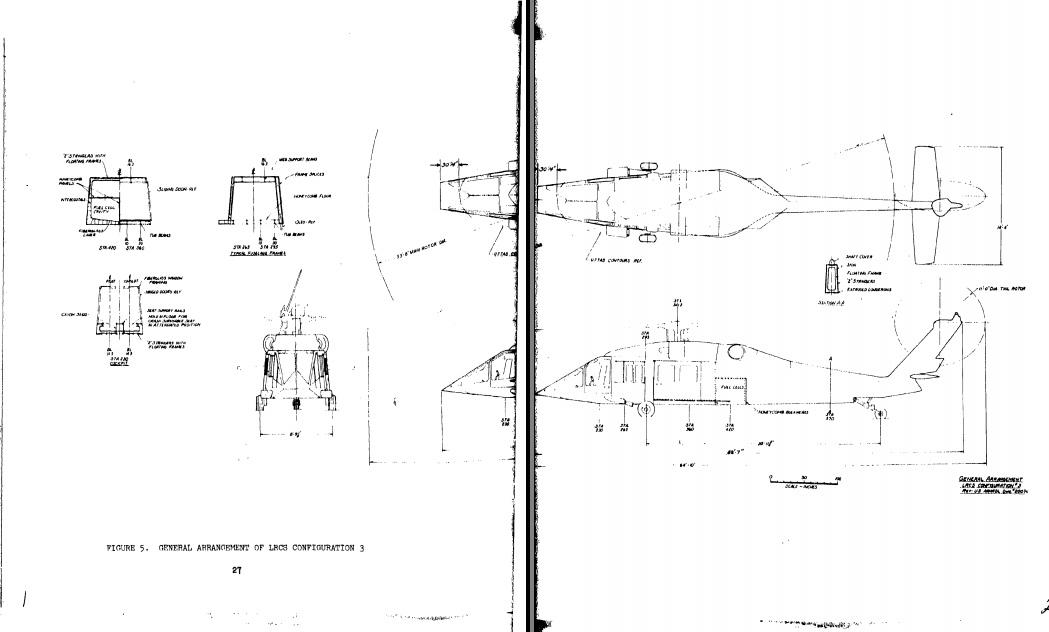

CONFIGURATION 3

This configuration is basically a flat side cross section airframe having sides canted inward 50 and is tapered in width from a narrow cockpit section to a transition section as wide as the baseline UH60A. The tail-cone is a rectangular section which is narrower than the baseline. The narrow cockpit causes the pilot and copilot seats to be spaced closer to each other; space for four-across seating in the main cabin is decreased. The cockpit and main cabin floors are at the same height from the ground as the baseline. The slope of the windshields may cause problems of visibility for the flight crew. Minor modifications of the mold lines for the transition and tail-cone sections were made to properly house the tail rotor shaft of the baseline UH60A.

ADVANCED MATERIAL APPLICATION

Advanced composite materials can be used in the construction of the three fuselage shapes considered in this study. Studies, have shown that the use of composite materials can reduce both fuselage weight and cost. The fuselages of this study are relatively lightly loaded compared to fixed-wing aircraft. To efficiently use advanced materials in the fuselages, very light composite skins are used in the post-buckled stress state. [...]

CONCLUSIONS

Structural concepts developed for the three LECS configurations showed that extensive reshaping, as exemplified by Configuration 2, would increase fuselage weight from that of the baseline UH-60A fuselage by 223 pounds and cost by 3.65 percent. When advanced materials were used Configuration 2 decreased

from the baseline fuselage weight and cost by 116 pounds and 3.98 percent respectivdly. Total aircraft performance capability was degraded primarily by drag effects. The aerodynamic analysis indicated that Configuration 2 would have a vertic climb rate at 15 percent of the baseline. Weight, cost, and performance penalties were less in Configurations 3 and 1 respectively.

Based on the results of this study, the following conclusions are made:

1. The use of advanced materials can result in both weight and cost savings over the baseline fuselage, even with the most severe change in LRCS configurations presented.

2. Without the use of advanced materials, the LRCS Configurations 2 and 3 significantly increase both weight and cost of the total aircraft compared to the baseline UH60A.

3. Minor changes to the nose section of Configuration 1 result in negligible fuselage difference to the weight and cost of the fuselage.

4. Consideration of the total aircraft attributes show that vertical drag penalties appear to be of greater magnitude than the structural weight changes involved with the fuselages of Configurations 2 and 3.

Even with the use of advanced materials, the vertical drag penalty exceeds any weight savings.

The sketch was revised to take the document into consideration (without forgetting it was issued at the end of the 70s). Even the main rotor was redesigned to make its head slightly larger (with a noise reduction cover sheltering the motion-control technology used to input low-frequency variations of rotor blade pitch-angle, as tested by NASA) .

One last thing worth a mention.

In the aftermath of the crash landing, on May 5, Jon Nowinski, an investigative reporter and founder of the Smoking Gun Research Agency (Welcome to the SGRA...) sent me an email to let me know that:

[... ] over the last few days there has been an increased number of late-night helicopter flights to the Sikorsky plant. While that doesnt entirely stand out as odd, it is interesting to note that normally these flights are related to testing aircraft, as well as consistant with what happens when a Sikorsky helo goes down in military action. After an accident like that, military investigators and officials frequently come out to the Sikorsky plan for a debriefing during which they review the operation

3

1

Stealth Black Hawk updated rendering: 1978 document suggests a different shape for the modified UH-60 « David Cenciotti's weblog

Three fuselage configurations for low radar cross sections were developed by the Applied Technology Laboratory. [...] The main rotor pylon fairings and tail surfaces aft of a tail fold hinge for each configuration were the same as those for the baseline UH60A. In the initial portion of this study, the weight and costs (percent of total) were developed for sections of the baseline UH60A fuselage. [...] Structural concepts were developed which could be applied to each configuration using conventional materials. An assessment of safety, fail-safety, and maintainability for each configuration was performed. The change in structural weight and the percentage change in cost for each configuration using the concepts developed were compared to those of the baseline. One concept was selected and applied to the three configurations.

Having selected the structural concept with the lowest weight change and percentage cost change for the three fuselage configurations, the effect on weight and costs using advanced materials was developed and applied to the three configurations. To evaluate the impact of the results of the fuselage study, design attributes of six helicopters were developed using a Helicopter Design Model (HDM) computer program.

Three low radar cross section fuselage configurations for this study were developed by the Applied Technology Laboratory. The first configuration slightly modified the nose section from the baseline configuration; the second configuration changed the fuselage shape along the lines of a truncated triangular prism; the third extended canted flat side shaping throughout the fuselage. The tail surfaces and main rotor pylon fairing were the same as those of the baseline UH60A.

CONFIGURATION 1

This configuration alters the baseline fuselage forward of the mid-cabin section (the cockpit). Although this configuration is different from the baseline, the internal structure must be compatible with the forward cabin to avoid a heavy joining structure. The overall length is slightly increased due to this configuration.

CONFIGURATION 2

This configuration is basically a trapezoidal cross section airframe having sides canted inward 30° and made up of flat exterior structural panels. This configuration is wider at the bottom of the fuselage and narrower at the top of the fuselage than the baseline. This configuration is slightly longer than the baseline UH60A, and its overall height is slightly larger than the baseline. The increased length, width, and height of Configuration 2 does not allow an aircraft of this size to meet the air transportability requirements of the baseline. The narrow upper fuselage causes the pilot and copilot seats to be spaced closer to each other, and shoulder room in the main cabin is decreased. The main cabin floor is approximately 6 inches higher than the baseline from the ground. The increased floor-to-ground height causes difficulties for combat troops to enter or leave the aircraft quickly. Minor modifications of the mold lines for the transition and tail-cone sections were made to properly house the tail rotor shaft of the baseline UH60A.

CONFIGURATION 3

This configuration is basically a flat side cross section airframe having sides canted inward 50 and is tapered in width from a narrow cockpit section to a transition section as wide as the baseline UH60A. The tail-cone is a rectangular section which is narrower than the baseline. The narrow cockpit causes the pilot and copilot seats to be spaced closer to each other; space for four-across seating in the main cabin is decreased. The cockpit and main cabin floors are at the same height from the ground as the baseline. The slope of the windshields may cause problems of visibility for the flight crew. Minor modifications of the mold lines for the transition and tail-cone sections were made to properly house the tail rotor shaft of the baseline UH60A.

ADVANCED MATERIAL APPLICATION

Advanced composite materials can be used in the construction of the three fuselage shapes considered in this study. Studies, have shown that the use of composite materials can reduce both fuselage weight and cost. The fuselages of this study are relatively lightly loaded compared to fixed-wing aircraft. To efficiently use advanced materials in the fuselages, very light composite skins are used in the post-buckled stress state. [...]

CONCLUSIONS

Structural concepts developed for the three LECS configurations showed that extensive reshaping, as exemplified by Configuration 2, would increase fuselage weight from that of the baseline UH-60A fuselage by 223 pounds and cost by 3.65 percent. When advanced materials were used Configuration 2 decreased

from the baseline fuselage weight and cost by 116 pounds and 3.98 percent respectivdly. Total aircraft performance capability was degraded primarily by drag effects. The aerodynamic analysis indicated that Configuration 2 would have a vertic climb rate at 15 percent of the baseline. Weight, cost, and performance penalties were less in Configurations 3 and 1 respectively.

Based on the results of this study, the following conclusions are made:

1. The use of advanced materials can result in both weight and cost savings over the baseline fuselage, even with the most severe change in LRCS configurations presented.

2. Without the use of advanced materials, the LRCS Configurations 2 and 3 significantly increase both weight and cost of the total aircraft compared to the baseline UH60A.

3. Minor changes to the nose section of Configuration 1 result in negligible fuselage difference to the weight and cost of the fuselage.

4. Consideration of the total aircraft attributes show that vertical drag penalties appear to be of greater magnitude than the structural weight changes involved with the fuselages of Configurations 2 and 3.

Even with the use of advanced materials, the vertical drag penalty exceeds any weight savings.

The sketch was revised to take the document into consideration (without forgetting it was issued at the end of the 70s). Even the main rotor was redesigned to make its head slightly larger (with a noise reduction cover sheltering the motion-control technology used to input low-frequency variations of rotor blade pitch-angle, as tested by NASA) .

One last thing worth a mention.

In the aftermath of the crash landing, on May 5, Jon Nowinski, an investigative reporter and founder of the Smoking Gun Research Agency (Welcome to the SGRA...) sent me an email to let me know that:

[... ] over the last few days there has been an increased number of late-night helicopter flights to the Sikorsky plant. While that doesnt entirely stand out as odd, it is interesting to note that normally these flights are related to testing aircraft, as well as consistant with what happens when a Sikorsky helo goes down in military action. After an accident like that, military investigators and officials frequently come out to the Sikorsky plan for a debriefing during which they review the operation

Hi, the entire Pakistan leadership and Pakistan Armed Forces high command are a bunch of hijras. You give them a few dollars and they will line up to...

/*************************************/

Pakistan returns U.S. helicopter from bin Laden raid - Yahoo! News

Pakistan returns U.S. helicopter from bin Laden raid

Stewart Phil Stewart 6 mins ago

WASHINGTON (Reuters) Pakistan has returned to the United States wreckage of a U.S. helicopter destroyed during the raid that killed Osama bin Laden, a Pentagon official told Reuters on Tuesday, but the gesture was expected to do little to improve strained ties.

The U.S. Navy SEAL team that stormed bin Laden's compound in Abbottabad, Pakistan, on May 2 blew up the chopper after it was damaged during a hard landing. They wanted keep sensitive U.S. technology out of enemy hands.

But bits of the helicopter, including the tail section, remained behind and the United States demanded that Pakistan return them to U.S. custody.

"It (the wreckage) was returned over the weekend and is now back in the United States," Pentagon spokesman Colonel Dave Lapan said.

The raid that killed bin Laden badly damaged U.S.-Pakistan relations, and nagging questions remain in Washington about how bin Laden managed to go unnoticed for years in the garrison town of Abbottabad, only 30 miles from Pakistan's capital, Islamabad. Some U.S. officials speculate he must have had support.

In turn, Pakistan has branded the raid a violation of its sovereignty, since Islamabad was not informed about the U.S. operation until it was over. Pakistan's parliament has threatened to cut supply lines to U.S. forces in Afghanistan if there are more military incursions.

Senator John Kerry, on a trip to Islamabad on May 16, described a Pakistani pledge to return the chopper's wreckage as one step needed to rebuild trust between the two countries which was badly damaged by the raid.

TOO LITTLE, TOO LATE?

But Bruce Riedel, a former CIA official who has advised President Barack Obama on policy in Pakistan and Afghanistan, said returning the helicopter fell far short of what it would take to mend frayed ties.

"It's too little, too late to change the downward spiral in U.S.-Pakistani relations," Riedel said.

Even before bin Laden's death, bilateral ties had reached a low point over Pakistan's arrest of a CIA contractor and mounting U.S. drone strikes in Pakistan's western regions.

The government of President Asif Ali Zardari, along with Pakistan's even more powerful military leaders, has denied any prior knowledge of bin Laden's whereabouts.

But some U.S. lawmakers are calling for a radical shift in U.S. policy on Pakistan as officials brace themselves for possible revelations about Pakistani complicity in data seized from bin Laden's compound.

On Tuesday, U.S. Defense Secretary Robert Gates acknowledged the "trust deficit" between the two countries. But he also said Pakistan was too important to walk away from.

"Pakistan is very important, not just because of Afghanistan but because of its nuclear weapons and because of the importance of stability in the subcontinent," Gates told an audience at the American Enterprise Institute, a Washington think-tank.

"So we need to keep working at this."

(Additional reporting by Missy Ryan and David Alexander; Editing by Bill Trott)

/*************************************/

Pakistan returns U.S. helicopter from bin Laden raid - Yahoo! News

Pakistan returns U.S. helicopter from bin Laden raid

Stewart Phil Stewart 6 mins ago

WASHINGTON (Reuters) Pakistan has returned to the United States wreckage of a U.S. helicopter destroyed during the raid that killed Osama bin Laden, a Pentagon official told Reuters on Tuesday, but the gesture was expected to do little to improve strained ties.

The U.S. Navy SEAL team that stormed bin Laden's compound in Abbottabad, Pakistan, on May 2 blew up the chopper after it was damaged during a hard landing. They wanted keep sensitive U.S. technology out of enemy hands.

But bits of the helicopter, including the tail section, remained behind and the United States demanded that Pakistan return them to U.S. custody.

"It (the wreckage) was returned over the weekend and is now back in the United States," Pentagon spokesman Colonel Dave Lapan said.

The raid that killed bin Laden badly damaged U.S.-Pakistan relations, and nagging questions remain in Washington about how bin Laden managed to go unnoticed for years in the garrison town of Abbottabad, only 30 miles from Pakistan's capital, Islamabad. Some U.S. officials speculate he must have had support.

In turn, Pakistan has branded the raid a violation of its sovereignty, since Islamabad was not informed about the U.S. operation until it was over. Pakistan's parliament has threatened to cut supply lines to U.S. forces in Afghanistan if there are more military incursions.

Senator John Kerry, on a trip to Islamabad on May 16, described a Pakistani pledge to return the chopper's wreckage as one step needed to rebuild trust between the two countries which was badly damaged by the raid.

TOO LITTLE, TOO LATE?

But Bruce Riedel, a former CIA official who has advised President Barack Obama on policy in Pakistan and Afghanistan, said returning the helicopter fell far short of what it would take to mend frayed ties.

"It's too little, too late to change the downward spiral in U.S.-Pakistani relations," Riedel said.

Even before bin Laden's death, bilateral ties had reached a low point over Pakistan's arrest of a CIA contractor and mounting U.S. drone strikes in Pakistan's western regions.

The government of President Asif Ali Zardari, along with Pakistan's even more powerful military leaders, has denied any prior knowledge of bin Laden's whereabouts.

But some U.S. lawmakers are calling for a radical shift in U.S. policy on Pakistan as officials brace themselves for possible revelations about Pakistani complicity in data seized from bin Laden's compound.

On Tuesday, U.S. Defense Secretary Robert Gates acknowledged the "trust deficit" between the two countries. But he also said Pakistan was too important to walk away from.

"Pakistan is very important, not just because of Afghanistan but because of its nuclear weapons and because of the importance of stability in the subcontinent," Gates told an audience at the American Enterprise Institute, a Washington think-tank.

"So we need to keep working at this."

(Additional reporting by Missy Ryan and David Alexander; Editing by Bill Trott)

khurasaan1

FULL MEMBER

- Joined

- Jun 25, 2010

- Messages

- 1,773

- Reaction score

- 0

Just watchout for the Punishment from Allah SBWT on us....very soon....

Areesh

ELITE MEMBER

- Joined

- Mar 30, 2010

- Messages

- 45,128

- Reaction score

- 3

- Country

- Location

Hi, the entire Pakistan leadership and Pakistan Armed Forces high command are a bunch of hijras. You give them a few dollars and they will line up to...

Well so mane incidents of disgrace have happen in past few weeks I don't have a facepalm picture left to post here. Great work Pakistani establishment. We have started to realize why mir jafar's shouldn't be given important posts.

Manticore

RETIRED MOD

- Joined

- Jan 18, 2009

- Messages

- 10,115

- Reaction score

- 114

- Country

- Location

WTF they made a model kit of it

Similar threads

- Replies

- 1

- Views

- 2K

- Replies

- 1

- Views

- 1K

- Replies

- 23

- Views

- 5K

- Replies

- 12

- Views

- 1K