How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Made in India

- Thread starter SOHEIL

- Start date

gslv mk3

BANNED

- Joined

- Aug 4, 2012

- Messages

- 13,819

- Reaction score

- -18

- Country

- Location

Varroc, a global full system supplier of diverse automotive products headquartered in Aurangabad manufactures exterior lighting systems, body and chassis parts, engine valves, machined forgings, electrical & electronic systems for five automotive segments: 2-wheelers, 3-wheelers, 4-wheelers, commercial vehicles and off road vehicles.

Varroc operates from 35 manufacturing plants and 11 engineering centres spread across 10 countries.

Industry 4.0: IISc building India’s 1st smart factory in Bengaluru

BENGALURU: India's first smart factory — moving from automation to autonomy — where machines speak with each other, is being set up in Bengaluru.

A smart factory, armed with data exchange in manufacturing and the Internet of Things (IoT) is the future and experts are calling it revolution Industry 4.0. Reports peg the smart factory industry to touch $215 billion by by 2025 and there has been no major economy in the world that is not embracing it.

And, India's very own smart factory, the first one, is making progress at the Indian Institute of Science's (IISc) Centre for Product Design and Manufacturing (CPDM) with a seed funding from The Boeing Company.

CPDM Chairman Amaresh Chakrabarti, who spoke exclusively to TOI about the project, said: "Yes, it will actually be manufacturing things here. But it will be a scaled down version, we won't have the numbers of an actual factory." As for the funding, he said: "I can only say Boeing is giving us enough to implement the project. I cannot discuss details. But the project is revolutionary. Indian factories now have automation, we've made some progress there, but here, we are talking about a facility that is autonomous, thinking and working on its own."

Explaining that any factory have five main elements, machine and tools, people who use it, parts that get fabricated, and the environment in which all this happens, Chakrabarti said: "All these exist in our factory too, but they are all continuously collecting data, analysing it and using it attain the most optimal result."

Data is being collected through a variety of sensors. From the posture of the man welding, or cutting, to the kind of energy the welding machine is using and what damages it is bearing and when it needs to be replaced, there is data on everything. The factory is self aware. "It knows, when the man needs rest, it knows when a machine needs to be replaced or repaired, it knows the humidity, temperature, everything. This data that is collected goes through pre-analysis (meaning to convert it to a language that can be processed for analysis) and then the analysis happens and course correction is initiated whereever required," Chakrabarti said.

He added that the network-enabled framework employed for manufacturing here gives a huge scope for autonomy. "It is internet of things (IoT) that has enabled this. We have also made some headway in natural language processing, another big leap," he said.

Dr Rishi Bhatnagar, Chairman, of the Institution of Engineering and Technology (IET) India IoT Panel said: "It is fantastic that this is happening. The smart factory concept in India has been a little slow, and that's because here we aren't doing this because there is labour shortage or expensive labour, like in the West. Here we will do it to keep the competitive edge and provide customer satisfaction."

Varroc operates from 35 manufacturing plants and 11 engineering centres spread across 10 countries.

Industry 4.0: IISc building India’s 1st smart factory in Bengaluru

BENGALURU: India's first smart factory — moving from automation to autonomy — where machines speak with each other, is being set up in Bengaluru.

A smart factory, armed with data exchange in manufacturing and the Internet of Things (IoT) is the future and experts are calling it revolution Industry 4.0. Reports peg the smart factory industry to touch $215 billion by by 2025 and there has been no major economy in the world that is not embracing it.

And, India's very own smart factory, the first one, is making progress at the Indian Institute of Science's (IISc) Centre for Product Design and Manufacturing (CPDM) with a seed funding from The Boeing Company.

CPDM Chairman Amaresh Chakrabarti, who spoke exclusively to TOI about the project, said: "Yes, it will actually be manufacturing things here. But it will be a scaled down version, we won't have the numbers of an actual factory." As for the funding, he said: "I can only say Boeing is giving us enough to implement the project. I cannot discuss details. But the project is revolutionary. Indian factories now have automation, we've made some progress there, but here, we are talking about a facility that is autonomous, thinking and working on its own."

Explaining that any factory have five main elements, machine and tools, people who use it, parts that get fabricated, and the environment in which all this happens, Chakrabarti said: "All these exist in our factory too, but they are all continuously collecting data, analysing it and using it attain the most optimal result."

Data is being collected through a variety of sensors. From the posture of the man welding, or cutting, to the kind of energy the welding machine is using and what damages it is bearing and when it needs to be replaced, there is data on everything. The factory is self aware. "It knows, when the man needs rest, it knows when a machine needs to be replaced or repaired, it knows the humidity, temperature, everything. This data that is collected goes through pre-analysis (meaning to convert it to a language that can be processed for analysis) and then the analysis happens and course correction is initiated whereever required," Chakrabarti said.

He added that the network-enabled framework employed for manufacturing here gives a huge scope for autonomy. "It is internet of things (IoT) that has enabled this. We have also made some headway in natural language processing, another big leap," he said.

Dr Rishi Bhatnagar, Chairman, of the Institution of Engineering and Technology (IET) India IoT Panel said: "It is fantastic that this is happening. The smart factory concept in India has been a little slow, and that's because here we aren't doing this because there is labour shortage or expensive labour, like in the West. Here we will do it to keep the competitive edge and provide customer satisfaction."

gslv mk3

BANNED

- Joined

- Aug 4, 2012

- Messages

- 13,819

- Reaction score

- -18

- Country

- Location

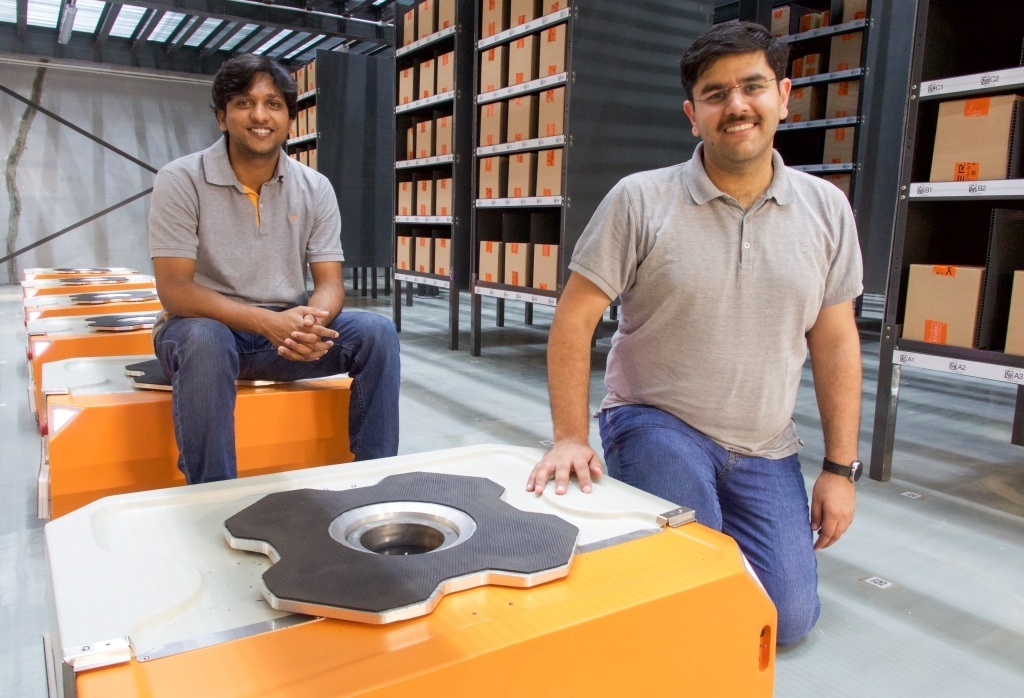

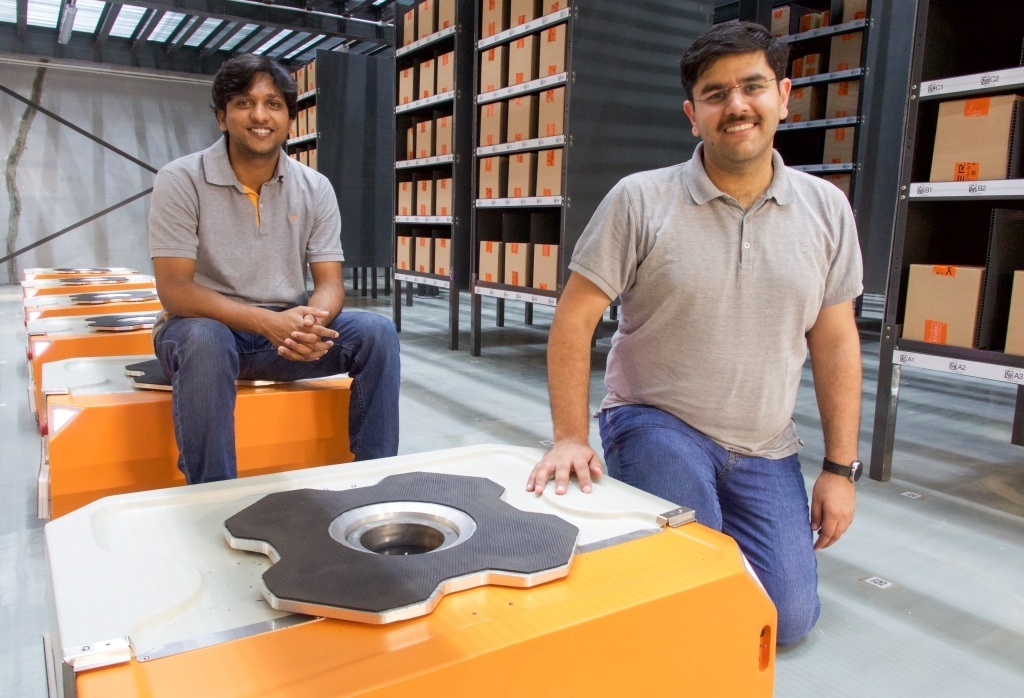

GreyOrange’s robots have taken over the shop floor

The five-year-old company commands a near monopoly 90% share of India’s warehouse automation market

GreyOrange’s chief executive Samay Kohli and chief technology officer Akash Gupta.

If you bought products online in India, chances are that your order has been picked up and sorted by a robot manufactured by GreyOrange.

Flipkart, Myntra, DTDC, GoJavas and Jabong are among the e-commerce and logistics firms that use these robots to automate distribution at their large warehouses across India. The start-up, which commands a near monopoly 90% market share of India’s warehouse automation market, is all of five years old.

In the complex world of e-commerce, these robots help companies and humans overcome operational challenges such as increasing costs, high order volumes, manpower issues, and short order-processing windows in addition to reducing errors.

GreyOrange, luckily, has been in the right place at the right time to take advantage of the e-commerce boom in India. Its offices across Mumbai, Bengaluru, Hyderabad and Chennai are testimony to its spectacular success in India.

Since being founded in 2011 by Samay Kohli and Akash Gupta, GreyOrange has grown to more than 550 employees today with over 33% of them working at its research and development (R&D) centre in Gurgaon. The robotics company is also present in Singapore, Hong Kong, the United Arab Emirates, Germany and Japan.

GreyOrange designs, manufactures and deploys advanced robotics systems for automation at warehouses, distribution and fulfilment centres and has an installed sortation capacity of around 12 million packets a day.

The company has three product lines: the butler system, the cross-belt sortation and the linear sortation system. Photos: Pradeep Gaur/Mint

The company is growing at about 300% year-on-year and while a major chunk of its revenue is still generated from India, GreyOrange aims to generate 70% of its sales from markets outside the country.

Both Kohli and Gupta are the quintessential boys next door, hailing from middle-class families. Gupta is from Kanpur having studied at Puranchandra Vidyaniketan while Kohli did his schooling at St Columba’s school in Delhi.

The two of them met as engineering students at BITS Pilani where a common love for robotics bound them.

As part of the humanoid programme at the Centre for Robotics and Intelligent Systems at BITS, they developed the AcYut in 2007, one of the first indigenously created humanoid robots in India. The duo also represented India in humanoid robotics competitions across 13 countries, winning the gold medal at the RoboGames (formerly ROBOlympics) in San Francisco in 2009.

While Gupta worked on several projects such as the design and implementation of an active underwater sonar stabilization system at the University of Louisiana to increase operating hours of the system under rough coastal weather conditions, Kohli was involved in organizing robotics workshops at more than 25 educational institutions globally—including Stanford University, Louisiana University, Massachusetts Institute of Technology and Indian Institutes of Technology. The duo also worked on a parallel project to create a technology-enabled haunted house, similar to a park in Disneyland that is completely automated, while they were doing their internship with C&C Technologies Inc. (now part of Oceaneering International Inc.) in the US. One thing led to another and from robotic competitions and workshops, the duo started doing product development for firms.

But it was only a chance meeting with German electronics engineer and entrepreneur Wolfgang Hoeltgen that the idea of GreyOrange took shape. Hoeltgen, 69, became the third co-founder of the company. The difference in both age and nationality is glaringly obvious but so far the trio has worked well. Hoeltgen had earlier worked at IBM Germany and the US in research, manufacturing, engineering and software development. In 1997, he started his own IT firm and conducted international projects in SAP consulting, guided mergers and acquisitions and founded the German-Indian Business Center at Hannover. Since the last four years, he has been involved with GreyOrange as co-founder, investor and mentor.

“As co-organizer of the world’s biggest science and technology show for young people I invited the AcYut team from BITS Pilani to Hannover to demonstrate their project in 2009. Somehow Akash and Samay selected me as their mentor that time and contacted me occasionally sharing their ideas,” says Hoeltgen. “I told them they would be wasting their talents, until they presented the idea of warehouse automation, which was exactly in-line with what I believed to be a perfect match of their capabilities and real worldwide demand. We met in India, put together a business plan, I liquidated my life insurance, one month later we rented office space, bought a CNC (computer numeric control) machine and hired the first engineers.”

And the rest as they say is history.

What began as a start-up with a team of seven on the ground floor of Kohli’s home, is now spread across 250,000 square feet of prime real estate in Gurgaon. Situated on National Highway 8, the Delhi-Gurgaon expressway, the GreyOrange office is in Orient Bestech Business Tower and occupies two-and-a-half floors. Not surprisingly, the office space is designed like a sprawling warehouse. It has long corridors with meeting rooms and open workspaces on either side where the team sits, brainstorms, crunches data and complex code. The culture is one of freedom, collaboration and openness. When the employees need a break, they have several options. They can either head to the cafeteria or the gym, play Xbox in the gaming arena, listen to some music in the music room, get pampered at the in-house beauty parlour or even take a nap in the sleeping room.

Says Naveen Boppana, lead engineer (mechanical): “GreyOrange’s culture is very different from the other companies I worked at in the past. I find that GreyOrange consciously maps your work against the impact that it creates. Therefore, there is always a high sense of accomplishment while working for GreyOrange. Needless to say, our cool new office is an added incentive to be a part of GreyOrange. Working in a vibrant and creative environment adds to your productivity. Facilities like a gym, cafeteria, gaming zone, etc. go a long way in establishing a work-life balance.”

GreyOrange employees are mostly engineers since robotics requires multidisciplinary skills such as electronics, electrical, mechanics, software, and firmware. It is, therefore, important that different engineering specializations coexist to create disruptive products and solutions.

Kohli adds: “We have often seen that many companies hire senior executives and leaders from the Silicon Valley and other global geographies for business roles. However, as GreyOrange is a hardcore hardware and R&D company, we focus on the experienced engineers out there. For example, we are getting on board a 62-year-old highly experienced Erlang expert, a global design senior expat from Hong Kong, and a mechanical design architect from Germany, which is the hub for world-class mechanical engineers.”

No wonder the company has acquired a cosmopolitan character that places a high emphasis on innovation and cutting-edge technology. “The fact that 33% of our workforce is dedicated to R&D is a testimony to our emphasis on innovation,” says Kohli. “We believe that it is very important to maintain a healthy workplace culture to ensure mutual learning and growth. Extensive training sessions help our employees to stay abreast with the latest skill requirements in the market and enhance their effectiveness.”

The company also gives employees the option to design and equip their workspace. A budget of Rs1 lakh is earmarked for this and employees can choose from a catalogue that includes chairs, workstations, upgraded laptops, high-capacity storage, laptop accessories, additional screens, even plants and decorative items for their workstations. It has been found that the engineers prefer latest desktops while the sales managers go for Macs. Another interesting activity the company does is what it calls the “GreyOrange Marathon”. Just like an athlete who runs 42km to complete the marathon, employees go through a period of 42 days where they take up targets/tasks that are above and beyond their core jobs.

“GreyOrange provides the opportunity to work with some of the smartest engineers. The focus is on solving the problems effectively and efficiently. Townhalls, biannual events like the GreyOrange Marathon, team activities, and excursions are the fun part of our culture. All this adds to the excitement of working at GreyOrange,” adds Paul John, a technical architect.

Gupta and Kohli’s zeal, passion for technology and energy belie their age—while Gupta turns 27 in a couple of months, Kohli is 30. Beyond their passion for robotics, they spend time learning about technology disruptions across the world.

Also read | A good product engine can disrupt any industry: GreyOrange’s Akash Gupta

As co-founders, the duo work in close collaboration. Gupta is the chief technology officer and his key focus is to drive the R&D engine for the company while as CEO, Kohli focuses on strategic planning for business growth across geographies and industries. “Since our products are a very important part of our business, Akash and I work very closely on the areas intersecting technology and business,” says Kohli.

GreyOrange has also worked to build a repertoire of international clients.

Among his its Indian clients, Abhishek Chakraborty, executive director of DTDC Express Ltd, is a happy customer. The firm has been using GreyOrange’s sortation system since early 2014 at four facilities in Hyderabad, Delhi, Bengaluru and Kolkata, and Chakraborty says because of the automated sortation system, DTDC has been able to handle 20-25% more volume per day in one hub—both in terms of count and tonnage, so there has been an improvement in throughput without adding any extra space. Automation has made the whole process smoother. The speed at which the company is able to process the shipment has seen a dramatic improvement. Chakraborty says a 6-7-hour turnaround of shipment now takes only 1-2 hours. Additionally, the machine helps the company accurately capture the volumetric weight, which is a key cost component, to help price each packet correctly. Workplace productivity has increased by 10-15% even though the volume has gone up, since the same manpower is engaged in more qualitative tasks.

Gupta and Kohli are responsive, innovative and collaborate to create great solutions, says Chakraborty. “DTDC found the right solution at the right price. You can find better technology but at a disproportionately higher cost and that is a discouragement,” he adds.

From the installation of the first machine to the fourth, there has been a marked improvement in scale and quality, adds Chakraborty.

Funding

Gurgaon-based GreyOrange has gone through two rounds of funding, a seed round where it raised $500,000 from Hoeltgen, angel investors and venture capital firm Blume Ventures. In the next round, it raised funds from investors including US-based Tiger Global Management, one of the world’s largest hedge funds and an active venture capital fund in India, having invested in companies like Flipkart. Gupta did not specify the exact break-up of the funding, except saying that the total amount raised so far was $35 million. The funds are primarily pumped in R&D, scaling up operations and international expansion. The company has two state-of-the art customer experience zones in Gurgaon and Singapore that simulates the environment in a warehouse, to provide first-hand experience of its solutions.

GreyOrange has three product lines: the butler system, the cross-belt sortation and the linear sortation systems across 50 installations.

Kohli is tight-lipped about how much the butler and the sorter cost, saying that costs vary from client to client, depending on the solution:

“Our products are designed to solve problems very specific to each business,” says Kohli. “For example, a business may want to reduce the rate of returns of their orders, whereas another business would want systems that help them reduce the time taken to process orders. We would be providing very different solutions to both these business problems after taking into consideration all the factors affecting the operations. Solutions will vary from business to business, industry to industry and geography to geography. Our costs are dependent on the solutions we offer, since solutions vary drastically, so do the costs associated with them.”

Expansion

Buoyed by the success in the domestic market, Gupta and Kohli are now expanding overseas. In Hong Kong and Singapore the company has a 14-member team. Gupta also mentions that GreyOrange invested in a firm in Japan that will help it instal the butler system in that region and it is now planning to set up an office in the Middle East. The company will cater to the fast-growing retail, consumer and packaged goods and e-commerce sectors with its state-of-the-art warehouse automation solutions for inventory management, order profiling and sorting. According to Kohli, GreyOrange’s entry into the Middle East will be a milestone in its overseas journey that began last year with the company entering Hong Kong, followed by Japan earlier this year and, most recently, China.

According to global e-commerce reports, the Middle Eastern market is seeing a rapid emergence of e-commerce, retail and consumer goods brands from all over the world. However, this immense growth opportunity comes with several operational challenges such as increasing complexity, scale and cost of supply-chain logistics, growing customer expectations, and emergence of newer business models, all leading to the need for data-driven processes. The Middle East also faces a major manpower challenge in terms of availability of the right skills, as well as the growing costs of manpower. GreyOrange’s robotic automation solutions, says Kohli, will address these challenges by helping organizations seamlessly transform and optimize their supply chains to minimize operational inefficiencies, reduce order fulfilment cycles and operational errors, optimize real estate, and help companies improve the overall experience for their end customers.

“The Middle East is an important market and has enormous potential for us particularly due to the emerging e-commerce sector,” says Kohli. “The industry is set to grow at a staggering 300% CAGR (compound annual growth rate) over the next five years. With the tremendous success GreyOrange has already seen in e-commerce in Asia and India, we are confident that we will be able to replicate it here and play a crucial role in helping the e-commerce firms across the market grow.”

The five-year-old company commands a near monopoly 90% share of India’s warehouse automation market

GreyOrange’s chief executive Samay Kohli and chief technology officer Akash Gupta.

If you bought products online in India, chances are that your order has been picked up and sorted by a robot manufactured by GreyOrange.

Flipkart, Myntra, DTDC, GoJavas and Jabong are among the e-commerce and logistics firms that use these robots to automate distribution at their large warehouses across India. The start-up, which commands a near monopoly 90% market share of India’s warehouse automation market, is all of five years old.

In the complex world of e-commerce, these robots help companies and humans overcome operational challenges such as increasing costs, high order volumes, manpower issues, and short order-processing windows in addition to reducing errors.

GreyOrange, luckily, has been in the right place at the right time to take advantage of the e-commerce boom in India. Its offices across Mumbai, Bengaluru, Hyderabad and Chennai are testimony to its spectacular success in India.

Since being founded in 2011 by Samay Kohli and Akash Gupta, GreyOrange has grown to more than 550 employees today with over 33% of them working at its research and development (R&D) centre in Gurgaon. The robotics company is also present in Singapore, Hong Kong, the United Arab Emirates, Germany and Japan.

GreyOrange designs, manufactures and deploys advanced robotics systems for automation at warehouses, distribution and fulfilment centres and has an installed sortation capacity of around 12 million packets a day.

The company has three product lines: the butler system, the cross-belt sortation and the linear sortation system. Photos: Pradeep Gaur/Mint

The company is growing at about 300% year-on-year and while a major chunk of its revenue is still generated from India, GreyOrange aims to generate 70% of its sales from markets outside the country.

Both Kohli and Gupta are the quintessential boys next door, hailing from middle-class families. Gupta is from Kanpur having studied at Puranchandra Vidyaniketan while Kohli did his schooling at St Columba’s school in Delhi.

The two of them met as engineering students at BITS Pilani where a common love for robotics bound them.

As part of the humanoid programme at the Centre for Robotics and Intelligent Systems at BITS, they developed the AcYut in 2007, one of the first indigenously created humanoid robots in India. The duo also represented India in humanoid robotics competitions across 13 countries, winning the gold medal at the RoboGames (formerly ROBOlympics) in San Francisco in 2009.

While Gupta worked on several projects such as the design and implementation of an active underwater sonar stabilization system at the University of Louisiana to increase operating hours of the system under rough coastal weather conditions, Kohli was involved in organizing robotics workshops at more than 25 educational institutions globally—including Stanford University, Louisiana University, Massachusetts Institute of Technology and Indian Institutes of Technology. The duo also worked on a parallel project to create a technology-enabled haunted house, similar to a park in Disneyland that is completely automated, while they were doing their internship with C&C Technologies Inc. (now part of Oceaneering International Inc.) in the US. One thing led to another and from robotic competitions and workshops, the duo started doing product development for firms.

But it was only a chance meeting with German electronics engineer and entrepreneur Wolfgang Hoeltgen that the idea of GreyOrange took shape. Hoeltgen, 69, became the third co-founder of the company. The difference in both age and nationality is glaringly obvious but so far the trio has worked well. Hoeltgen had earlier worked at IBM Germany and the US in research, manufacturing, engineering and software development. In 1997, he started his own IT firm and conducted international projects in SAP consulting, guided mergers and acquisitions and founded the German-Indian Business Center at Hannover. Since the last four years, he has been involved with GreyOrange as co-founder, investor and mentor.

“As co-organizer of the world’s biggest science and technology show for young people I invited the AcYut team from BITS Pilani to Hannover to demonstrate their project in 2009. Somehow Akash and Samay selected me as their mentor that time and contacted me occasionally sharing their ideas,” says Hoeltgen. “I told them they would be wasting their talents, until they presented the idea of warehouse automation, which was exactly in-line with what I believed to be a perfect match of their capabilities and real worldwide demand. We met in India, put together a business plan, I liquidated my life insurance, one month later we rented office space, bought a CNC (computer numeric control) machine and hired the first engineers.”

And the rest as they say is history.

What began as a start-up with a team of seven on the ground floor of Kohli’s home, is now spread across 250,000 square feet of prime real estate in Gurgaon. Situated on National Highway 8, the Delhi-Gurgaon expressway, the GreyOrange office is in Orient Bestech Business Tower and occupies two-and-a-half floors. Not surprisingly, the office space is designed like a sprawling warehouse. It has long corridors with meeting rooms and open workspaces on either side where the team sits, brainstorms, crunches data and complex code. The culture is one of freedom, collaboration and openness. When the employees need a break, they have several options. They can either head to the cafeteria or the gym, play Xbox in the gaming arena, listen to some music in the music room, get pampered at the in-house beauty parlour or even take a nap in the sleeping room.

Says Naveen Boppana, lead engineer (mechanical): “GreyOrange’s culture is very different from the other companies I worked at in the past. I find that GreyOrange consciously maps your work against the impact that it creates. Therefore, there is always a high sense of accomplishment while working for GreyOrange. Needless to say, our cool new office is an added incentive to be a part of GreyOrange. Working in a vibrant and creative environment adds to your productivity. Facilities like a gym, cafeteria, gaming zone, etc. go a long way in establishing a work-life balance.”

GreyOrange employees are mostly engineers since robotics requires multidisciplinary skills such as electronics, electrical, mechanics, software, and firmware. It is, therefore, important that different engineering specializations coexist to create disruptive products and solutions.

Kohli adds: “We have often seen that many companies hire senior executives and leaders from the Silicon Valley and other global geographies for business roles. However, as GreyOrange is a hardcore hardware and R&D company, we focus on the experienced engineers out there. For example, we are getting on board a 62-year-old highly experienced Erlang expert, a global design senior expat from Hong Kong, and a mechanical design architect from Germany, which is the hub for world-class mechanical engineers.”

No wonder the company has acquired a cosmopolitan character that places a high emphasis on innovation and cutting-edge technology. “The fact that 33% of our workforce is dedicated to R&D is a testimony to our emphasis on innovation,” says Kohli. “We believe that it is very important to maintain a healthy workplace culture to ensure mutual learning and growth. Extensive training sessions help our employees to stay abreast with the latest skill requirements in the market and enhance their effectiveness.”

The company also gives employees the option to design and equip their workspace. A budget of Rs1 lakh is earmarked for this and employees can choose from a catalogue that includes chairs, workstations, upgraded laptops, high-capacity storage, laptop accessories, additional screens, even plants and decorative items for their workstations. It has been found that the engineers prefer latest desktops while the sales managers go for Macs. Another interesting activity the company does is what it calls the “GreyOrange Marathon”. Just like an athlete who runs 42km to complete the marathon, employees go through a period of 42 days where they take up targets/tasks that are above and beyond their core jobs.

“GreyOrange provides the opportunity to work with some of the smartest engineers. The focus is on solving the problems effectively and efficiently. Townhalls, biannual events like the GreyOrange Marathon, team activities, and excursions are the fun part of our culture. All this adds to the excitement of working at GreyOrange,” adds Paul John, a technical architect.

Gupta and Kohli’s zeal, passion for technology and energy belie their age—while Gupta turns 27 in a couple of months, Kohli is 30. Beyond their passion for robotics, they spend time learning about technology disruptions across the world.

Also read | A good product engine can disrupt any industry: GreyOrange’s Akash Gupta

As co-founders, the duo work in close collaboration. Gupta is the chief technology officer and his key focus is to drive the R&D engine for the company while as CEO, Kohli focuses on strategic planning for business growth across geographies and industries. “Since our products are a very important part of our business, Akash and I work very closely on the areas intersecting technology and business,” says Kohli.

GreyOrange has also worked to build a repertoire of international clients.

Among his its Indian clients, Abhishek Chakraborty, executive director of DTDC Express Ltd, is a happy customer. The firm has been using GreyOrange’s sortation system since early 2014 at four facilities in Hyderabad, Delhi, Bengaluru and Kolkata, and Chakraborty says because of the automated sortation system, DTDC has been able to handle 20-25% more volume per day in one hub—both in terms of count and tonnage, so there has been an improvement in throughput without adding any extra space. Automation has made the whole process smoother. The speed at which the company is able to process the shipment has seen a dramatic improvement. Chakraborty says a 6-7-hour turnaround of shipment now takes only 1-2 hours. Additionally, the machine helps the company accurately capture the volumetric weight, which is a key cost component, to help price each packet correctly. Workplace productivity has increased by 10-15% even though the volume has gone up, since the same manpower is engaged in more qualitative tasks.

Gupta and Kohli are responsive, innovative and collaborate to create great solutions, says Chakraborty. “DTDC found the right solution at the right price. You can find better technology but at a disproportionately higher cost and that is a discouragement,” he adds.

From the installation of the first machine to the fourth, there has been a marked improvement in scale and quality, adds Chakraborty.

Funding

Gurgaon-based GreyOrange has gone through two rounds of funding, a seed round where it raised $500,000 from Hoeltgen, angel investors and venture capital firm Blume Ventures. In the next round, it raised funds from investors including US-based Tiger Global Management, one of the world’s largest hedge funds and an active venture capital fund in India, having invested in companies like Flipkart. Gupta did not specify the exact break-up of the funding, except saying that the total amount raised so far was $35 million. The funds are primarily pumped in R&D, scaling up operations and international expansion. The company has two state-of-the art customer experience zones in Gurgaon and Singapore that simulates the environment in a warehouse, to provide first-hand experience of its solutions.

GreyOrange has three product lines: the butler system, the cross-belt sortation and the linear sortation systems across 50 installations.

Kohli is tight-lipped about how much the butler and the sorter cost, saying that costs vary from client to client, depending on the solution:

“Our products are designed to solve problems very specific to each business,” says Kohli. “For example, a business may want to reduce the rate of returns of their orders, whereas another business would want systems that help them reduce the time taken to process orders. We would be providing very different solutions to both these business problems after taking into consideration all the factors affecting the operations. Solutions will vary from business to business, industry to industry and geography to geography. Our costs are dependent on the solutions we offer, since solutions vary drastically, so do the costs associated with them.”

Expansion

Buoyed by the success in the domestic market, Gupta and Kohli are now expanding overseas. In Hong Kong and Singapore the company has a 14-member team. Gupta also mentions that GreyOrange invested in a firm in Japan that will help it instal the butler system in that region and it is now planning to set up an office in the Middle East. The company will cater to the fast-growing retail, consumer and packaged goods and e-commerce sectors with its state-of-the-art warehouse automation solutions for inventory management, order profiling and sorting. According to Kohli, GreyOrange’s entry into the Middle East will be a milestone in its overseas journey that began last year with the company entering Hong Kong, followed by Japan earlier this year and, most recently, China.

According to global e-commerce reports, the Middle Eastern market is seeing a rapid emergence of e-commerce, retail and consumer goods brands from all over the world. However, this immense growth opportunity comes with several operational challenges such as increasing complexity, scale and cost of supply-chain logistics, growing customer expectations, and emergence of newer business models, all leading to the need for data-driven processes. The Middle East also faces a major manpower challenge in terms of availability of the right skills, as well as the growing costs of manpower. GreyOrange’s robotic automation solutions, says Kohli, will address these challenges by helping organizations seamlessly transform and optimize their supply chains to minimize operational inefficiencies, reduce order fulfilment cycles and operational errors, optimize real estate, and help companies improve the overall experience for their end customers.

“The Middle East is an important market and has enormous potential for us particularly due to the emerging e-commerce sector,” says Kohli. “The industry is set to grow at a staggering 300% CAGR (compound annual growth rate) over the next five years. With the tremendous success GreyOrange has already seen in e-commerce in Asia and India, we are confident that we will be able to replicate it here and play a crucial role in helping the e-commerce firms across the market grow.”

gslv mk3

BANNED

- Joined

- Aug 4, 2012

- Messages

- 13,819

- Reaction score

- -18

- Country

- Location

ISRO outsources medium size satellite manufacturing to Alpha Design Tecnologies led consortium

Bengaluru: Furthering the Make India push being given in aerospace and defence sector by the government, Bengaluru-based Alpha Design Technologies Private Design Technologies Private Ltd (ADTL) along with its consortium teams have inked a pact with Dr M Annadurai, Director, ISRO Satellite Centre (ISAC) on Saturday.

As per the contract, Alpha Design Tech will now undertake assembly, integration and testing (AIT) of IRNSS-1H satellites.

These are backup for present IRNSS series satellites & may feature indigenous atomic clocks.

Bengaluru: Furthering the Make India push being given in aerospace and defence sector by the government, Bengaluru-based Alpha Design Technologies Private Design Technologies Private Ltd (ADTL) along with its consortium teams have inked a pact with Dr M Annadurai, Director, ISRO Satellite Centre (ISAC) on Saturday.

As per the contract, Alpha Design Tech will now undertake assembly, integration and testing (AIT) of IRNSS-1H satellites.

These are backup for present IRNSS series satellites & may feature indigenous atomic clocks.

gslv mk3

BANNED

- Joined

- Aug 4, 2012

- Messages

- 13,819

- Reaction score

- -18

- Country

- Location

Cochin Shipyard Limited (CSL) is the largest ship building and maintenance facility in India. The yard has facilities to build vessels up to 1.1 Million tons and repair vessels up to 1.25 Million tons, the largest such facilities in India. CSL is also building the Indian Navy's first indigenous Vikrant class aircraft carrier.

The Cochin Shipyard Ltd.’s (CSL) bid to build a larger dry dock on its campus at Thevara, which will enable it to construct mammoth vessels such as LNG carrying vessels and bigger aircraft carriers, has got a fillip with the Union Ministry of Environment, Forest and Climate Change granting environment and CRZ clearance for the project.

The proposed dry dock, which will be 310-metre long and 75-metre wide, is estimated to cost Rs. 1,700 crore and the yard has set the ball rolling for issue of IPO to fund the construction. The PSU shipyard, where the country’s first indigenous aircraft carrier INS Vikrant is being built and the newly-acquired aircraft carrier INS Vikramaditya underwent its first refit, has two dry docks, with lengths of 270 metre and 255 metre, at the moment. The construction of the new dock will be carried out over an area of 15 acres on the CSL campus, which spreads over 170 acres.

The new drydock, it is learnt, will have a draft of 13 metre with a two-metre freeboard (which corresponds to the dry dock’s depth to the loading dock minus the dry dock’s draft). The yard has made it clear that the new dock will enhance its capacity to build 300-metre long LNG carriers, aircraft carriers of similar length and big oil and gas rigs.

patentneer

FULL MEMBER

- Joined

- May 15, 2010

- Messages

- 1,920

- Reaction score

- 0

But ironically have 480 hp truck engine in its arsenal

Only thing we currently lacks in propulsion is working Jet & Gas Turbine engine (prototype already available)

^^^

Lots of Gas Turbine engines are made regularly by BHEL.

Military and defence grade jet engines are also made in India, including the latest GTRE's Kaveri series.

Your comment is however, limited to top-notch, front-line single engine LCA Tejas type jet engine which is also under development, albeit late. Meanwhile GE 404/414 type engines are the mated to the Tejas.

Point to note is that the GE engines are the top-of-the-top of elite, A grade fighter jet engine. These engines are national projects and evolve contiguously. India's own Kaveri engine is in that league, and almost there; and when in full production mode, will also be supported by an array of researchers and developers (R&D) on a contiguous basis no doubt. Minor tweaks, for eg. today one of the biggest challenges with this engine type is Nitrogen Oxide (NOX) emissions problem !

gslv mk3

BANNED

- Joined

- Aug 4, 2012

- Messages

- 13,819

- Reaction score

- -18

- Country

- Location

Tata Motors-ISRO's Starbus fuel cell bus showcased in India

Tata Motors today showcased the country’s first fuel cell bus in Pune. Based on the model unveiled at the 2012 Auto Expo, the fuel cell-powered Starbus will be a zero-emission mode of public transport for intra-city commutes.

The company states that the battery-powered electric vehicles have their own limitations such as plug-in charging. In fuel cell-powered vehicles, hydrogen stored in a compressed form is made to combine with oxygen from air to generate electricity. This system only emits water vapour as the final byproduct. The company claims that the lack of external charging combined with the longer driving range makes fuel cells the best alternate to conventional electrics. In addition, the Starbus fuel cell bus comes equipped with idle-off system that shuts down the fuel cell once the motor is sensed to be idling.

Tata Motors has signed a MoU with ISRO in 2006 for providing technology in producing, storing and handling gaseous and liquid hydrogen. The ISRO team capitalised their years of cryogenic expertise to use liquid hydrogen to power engines. The Tata Motors and ISRO engineering team designed and developed the Fuel Cell Power System (FCPS) for the bus starting from 20KW to 120KW. The Starbus fuel cell bus was first unveiled at the Liquid Propulsion Systems Centre at the ISRO facility in Mahendragiri, Tamil Nadu, in 2013.

The other offerings that were showcased today include the Starbus electric, Starbus hybrid and Starbus LNG. The Starbus hybrid comes with new-generation Lithium-ion phosphate batteries (Prismatic Cell) that are charged by the BS-IV compliant diesel motor. Tata Motors claims that the series hybrid technology offers lowest cost of ownership and considerably lower emissions compared to conventional buses. Furthermore, the hybrid bus can run on pure electric mode, for around 30-35 per cent of the total travel distance. The Starbus LNG’s aim is to provide lower carbon emissions and better fuel economy with lower operating costs. The LNG buses will have a claimed range of more than 700km in one tankful.

Tata Motors today showcased the country’s first fuel cell bus in Pune. Based on the model unveiled at the 2012 Auto Expo, the fuel cell-powered Starbus will be a zero-emission mode of public transport for intra-city commutes.

The company states that the battery-powered electric vehicles have their own limitations such as plug-in charging. In fuel cell-powered vehicles, hydrogen stored in a compressed form is made to combine with oxygen from air to generate electricity. This system only emits water vapour as the final byproduct. The company claims that the lack of external charging combined with the longer driving range makes fuel cells the best alternate to conventional electrics. In addition, the Starbus fuel cell bus comes equipped with idle-off system that shuts down the fuel cell once the motor is sensed to be idling.

Tata Motors has signed a MoU with ISRO in 2006 for providing technology in producing, storing and handling gaseous and liquid hydrogen. The ISRO team capitalised their years of cryogenic expertise to use liquid hydrogen to power engines. The Tata Motors and ISRO engineering team designed and developed the Fuel Cell Power System (FCPS) for the bus starting from 20KW to 120KW. The Starbus fuel cell bus was first unveiled at the Liquid Propulsion Systems Centre at the ISRO facility in Mahendragiri, Tamil Nadu, in 2013.

The other offerings that were showcased today include the Starbus electric, Starbus hybrid and Starbus LNG. The Starbus hybrid comes with new-generation Lithium-ion phosphate batteries (Prismatic Cell) that are charged by the BS-IV compliant diesel motor. Tata Motors claims that the series hybrid technology offers lowest cost of ownership and considerably lower emissions compared to conventional buses. Furthermore, the hybrid bus can run on pure electric mode, for around 30-35 per cent of the total travel distance. The Starbus LNG’s aim is to provide lower carbon emissions and better fuel economy with lower operating costs. The LNG buses will have a claimed range of more than 700km in one tankful.

Last edited:

MULUBJA

BANNED

- Joined

- Aug 5, 2013

- Messages

- 2,584

- Reaction score

- -10

- Country

- Location

Alstom Bharat Forge facility at Sanand in Gujarat

Alstom Bharat Forge facility at Sanand in Gujarat commences production - YouTube

I can assure you that they will have a great experiance in Gujarat. People can hardly imagine the friendly atmosphere exist here between boss and staff and people around the factory. It is just like familiy.

Ship Building Capacity of Major Indian Shipyards By Types & Size as on 2014

View attachment 280074

@Nilgiri

In our small dock, we manufacture tug nd upto 4000 ton ships with ease like child's play.

MULUBJA

BANNED

- Joined

- Aug 5, 2013

- Messages

- 2,584

- Reaction score

- -10

- Country

- Location

Where do you work, bro ?

Did you read my reply?

gslv mk3

BANNED

- Joined

- Aug 4, 2012

- Messages

- 13,819

- Reaction score

- -18

- Country

- Location

Made In India Engines

Kirloskar DV Series Engines (400 to 1210 HP)

for Industrial & Marine application

gslv mk3

BANNED

- Joined

- Aug 4, 2012

- Messages

- 13,819

- Reaction score

- -18

- Country

- Location

Nilgiri

BANNED

- Joined

- Aug 4, 2015

- Messages

- 24,797

- Reaction score

- 81

- Country

- Location

This thread is absolutely amazing!

Great updates @gslv mk3

Do you know of any updates/videos for this:

https://qz.com/302016/heres-a-look-inside-ges-brand-new-manufacturing-facility-in-pune/

Great updates @gslv mk3

Do you know of any updates/videos for this:

https://qz.com/302016/heres-a-look-inside-ges-brand-new-manufacturing-facility-in-pune/

gslv mk3

BANNED

- Joined

- Aug 4, 2012

- Messages

- 13,819

- Reaction score

- -18

- Country

- Location

This thread is absolutely amazing!

Thank you sir.

Didn't hear anything about their manufacturing facility recently.

Last edited:

MULUBJA

BANNED

- Joined

- Aug 5, 2013

- Messages

- 2,584

- Reaction score

- -10

- Country

- Location

Kirloskar DV Series Engines (400 to 1210 HP)

View attachment 377837

View attachment 377838

for Industrial & Marine application

Can these be used in Tanks?

gslv mk3

BANNED

- Joined

- Aug 4, 2012

- Messages

- 13,819

- Reaction score

- -18

- Country

- Location

Can these be used in Tanks?

DRDO is already developing Bharat Power Pack (1500 HP) with industry participation. I'm sure that Kirloskar will be a industry partner in that.

Similar threads

- Replies

- 0

- Views

- 220

- Replies

- 0

- Views

- 192

- Replies

- 0

- Views

- 150

- Replies

- 0

- Views

- 143