@Nilgiri

At first place, it's the problem of management & investment.

Wafer Fabrication Facility at the SemiConductor Laboratory, Chandigarh

Besides that, ever heard of NAVIKA?

We have been producing chips without fabs, just not mass producing for civil use, even besides that we've very good design houses outsourcing plenty to foreign firms.

Chinese members seem to obsessed with manufacturing for trolling Indians (

not to forget that China license produces British Company ARM's chips itself

), designing houses too matter a lot.

India has many nice design houses who not only served ISRO & DRDO but foreign firms too.

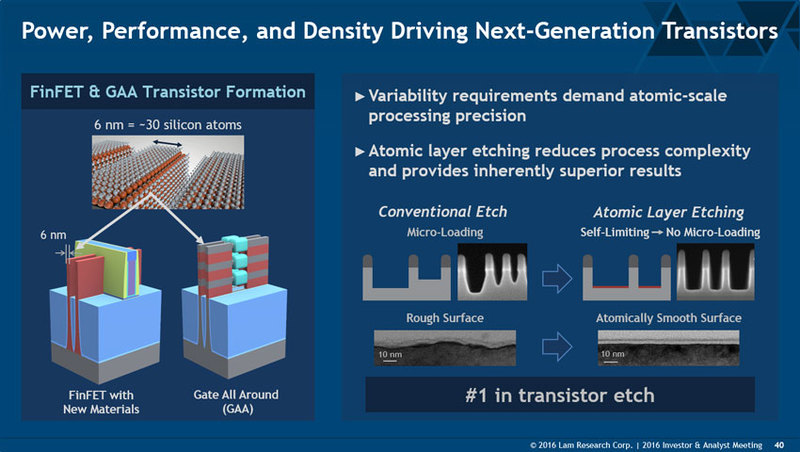

How about having atomic sized semiconductors? Transistors with just 30 silicon atoms?

Pic above: Atomic scale structure of FinFETs and the etching

India is designing chips <7nm and you are taking entire credit away from India because India will need to invest around $100 billions to build manufacturing capability of modern phone chips which it can't afford right now?

Is that fair honestly tell me.

Anyway, OT:

Challenges:

- The initial investment is high, Indian firms won't invest such a big amount without a guarantee for profit.

- The skilled labour issue.

How get over?

- Let the government do entire initial funding! http://m.economictimes.com/industry...al-semiconductor-hub/articleshow/57261190.cms

- As skilled labourers' number has to be increased gradually, you have another solution to make technology parks to concentrate firms (like we did for Software & IT industry, this time for hardware). And simply, it won't make sense if you are making chips in Prantij, screens & cameras in Noida or printed circuits somewhere in Bangalore before you assemble them in New Delhi. Taiwan was successful because Fab & other tech units are side by side.

For all sorts of Noob here, I think I have been tracking the semiconductor issue closer than you since last 5-6 years and may be slightly knowing more than you.

Though, I know that putting link of other forums is violation of rules, I'm still doing it.

http:// defence forumindia. com/forum/threads/indian-electronics-and-semiconductor-manufacturing-industry.77940/page-2

[Remove the spaces and use the link, I hope all of concerns raised by bussard ramjet must have been clarified here].

In the similar way by which SinoSoldier injects common sense to Chinese? Isn't that?

This site is littered with false flaggers, specially Pakistanis pretending to be anyone else.

abcxyz, Bharat Muslim, faithfulguy, Bussard Ramjet, Indian Patriot, endyashainin and a lot more.

I trolled some of em in Hindi/Urdu and got the responses, enough.

If you are still willing to hide faces behind em, go.

I left this site because of them and came back just for semiconductor thread.