A Triumph for Indian innovation : The 1200 kV UHVAC power system

IEEMA while clearly enthused by the huge august gathering stated that the initiation of 1200 kV AC technology was the tipping point in the

Indian Transmission Technology. IEEMA, whose 25 members formed the bulk total 35 participants actively involved in the project. According to IEEMA "more such research and development initiatives are required in the country, this initiative also offers a huge opportunity to the domestic manufacturers to upgrade to 1200kV level and opens up the huge global markets for such exports".

India's power system is poised for accelerated growth. Peak demand in India is expected to increase to more than 500,000 MW by 2027 for which installed generation capacity of about 700,000MW is required. Obviously, electricity generated needs to be evacuated, transmitted & distributed efficiently. Development of large transmission network for transfer of bulk power over long distances poses various challenges including environmental & technical, particularly in a country like India where additional challenges like Right-of-Way (ROW), Environmental aspects etc.too are thrown up. RoW today is a critical constraint, given the reluctance of the landowners to part with their land. Further, majority of the power is generated in the north eastern region of India while the demand centers are primarily located in the more industrialized western, southern and central regions, this situation is however changing slowly with the planning & implementation of Ultra Mega power projects (UMPP) across the country and near to coastal areas.

All these challenges with manifold increase of

power transfer requirement necessitate quantum jump in transmission voltage level. The existing 400kV line can transfer about 600MW power whereas 800kV line has loading capacity of 1200MW-2400MW. The transmission capacity of 1200kV is between 6000 MW to 8000 MW and hence a much needed solution for meeting above challenges. To meet the long-term power transfer requirement, a large transmission network is being planned in India interconnecting all the pocketed generating resources.

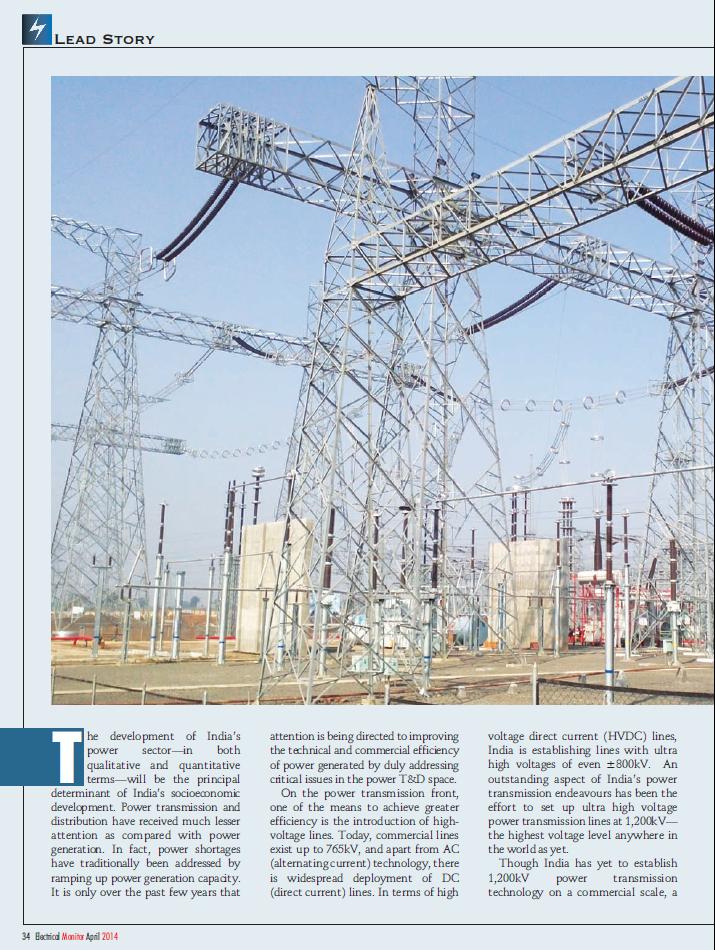

Taking into consideration the increased power transfer requirement to meet the above challenges, an alternative 1200 kV AC transmission system between various regions is also being explored. In a first such initiative in the country, 35 manufacturers have joined hands with Powergrid to establish a 1200kV UHV AC Test Station at Bina, Madhya Pradesh, to initiate development of 1200kV transmission equipment indigenously.

The test line is being constructed with two 1200kV test bays in which the leading manufacturers are providing main equipments such as transformers, surge arresters, circuit breakers, instrument transformers and transmission line hardware and accessories. These test bays and test line shall be used for various field tests/ trials so that the results and feedback can be used for developing field proven equipment as well as to gain initial operational experience. Powergrid is likely to construct 1200 kV Transmission Lines between Wardha and Aurangabad to usher in 1200 kV era in the country.

The test bays and the test line shall be used by the manufacturers and Powergrid for various field tests so that the results and feedback can be used for developing the proven equipment of 1200kV system in India as well as gain initial operational experience. The test station is likely to be commissioned in early 2011. This endeavor shall benefit the Indian Power sector and manufacturers as availability of 1200kV class equipment within the country will enable optimization of transmission cost and also help during the operation and maintenance phase.

India is starved for electricity despite the

Indian power system's present installed capacity of about 162,000 MW. Demand for electricity is growing at an accelerated pace. Peak demand is expected to increase to more than 500,000 MW by 2027 for which installed capacity of about 700,000MW is required. To meet the growing demand, the government is actively working on increasing generation capacity and encouraging new investments in the sector especially through private participation through Single window clearances for UMPPs - faster land acquisition & environmental clearances etc, zero customs duty for project imports. This is one part of the story.

The other part of the story is that electricity generated also needs to be efficiently transferred over large distances and with minimum losses.. India being a large country the distances involved are quite long, particularly when the bulk of the power is generated by the pocketed generating resources in Eastern, North-eastern Regions and consumed in the with bulk load centers in the other regions. To interconnect these effectively and meet the long-term power transfer requirement, a large transmission network is being planned in India. However it is faced with many challenges like increased transmission losses, large short circuit requirements, Right-of-Way(RoW) and resultant environmental issues. Hence urgent solutions are needed to overcome these challenges.

After conducting extensive studies and in the given circumstances the Indian transmission utility, Powergrid felt that a1200kV transmission line would be the most apt for transfer of bulk power efficiently. The electricity transmission capacity of 1200kV system is between 6000 MW to 8000 MW - which is about twice as that of the 765kV system and is about 6 times that of the currently widely used 400kV system.

To elaborate further, the existing 400kV lines on an average can transfer about 600MW power whereas 800kV lines have loading capacity of 1200MW-2400MW. However, As already mentioned higher Transmission voltage, has its own problems like requirement of wider transmission corridors (Right-of-Way or ROW), bigger & higher towers, resulting environmental impact due to larger use of space etc Increase in short circuit level, reduction of losses etc.

We can get an idea about the Voltage vis-à-vis Right-of-Way requirements from the table 1.1 below You will note that higher transmission voltages increase the space required for creating a transmission corridor by almost 100% thereby increasing costs incurred in acquiring land (if it is first available) & the resultant environmental impact but at the same time it also enables bulk power transfer. 1200kV UHVAC system could the panacea for our power transfer issues. So what are the other countries doing? Let's checkout the scenario in ultra high voltage bulk transfer systems elsewhere;

- The First 1200 kV system was field tested & commissioned in USSR in 1985 after 12 years of research, however it was unfortunately discontinued after disintegration of USSR.

- Japan started developmental work of 1000 kV UHV system in 1978. Japan has also developed 1100kV test station which is in service since 1993. Developmental tests are still continuing.

- As usual China a late starter is catching up very fast. China started their 1100 kV UHV system developmental work very recently i.e. in 2005. In January 2009, 1100kV transmission project was constructed in China. Three (03) Numbers 1100kV Transmission Stations have been constructed and are in operation almost for a year. Further additional 1100kV Transmission project are under planning and design stage in China for bulk transfer of power.

- Other countries like USA and Brazil are also considering development of UHV AC transmission system in their network.

Powergrid embarked on a historical journey and decided to set up a 1200kV National Test Station at Bina in Madhya Pradesh. Powergrid although boldly opting for a 1200 kV UHVAC system faced a major challenge - Lack of proven 1200kV technology, since even globally there is very little experience on successful use of 1200kV technology. The solution was to develop the technology indigenously which will also be advantageous to the nation in the long term.

Powergrid decided to capitalize on the manufacturing and technology skills of the mature Indian electrical equipment manufacturers and decided to develop the required equipment with indigenous technology in collaboration with CEA, CPRI, IEEMA and other equipment manufacturers.(The Indian electrical industry over the last 6 decades has evolved into a mature industry and acquired the necessary skills & technology to sustain itself in the long term). In fact today we can proudly say that 95% of all the equipment in India is of Indian make.

An initial corpus of Rs 100 crores was set aside to start the Test Station initiative in 2007 with a final cost of about Rs 800 crores.

Establishment of 1200kV UHVAC Test Station at Bina (WR) - entails;

- Construction of 2 nos. 1200kV Bays and 2 nos. 400kV bays along with 2 nos. 1200/400/33kV 333MVA Transformers.

- Construction of two nos. 1200kV Test Lines of one km length (one single circuit and one double circuit)

- Setting up of Test facilities

A Project Steering Committee under the leadership of Powergrid and comprising of representative from Central Electrical Authority, electrical equipment manufacturers, CPRI and IEEMA in 2007 was formed. Since then 13 formal interactions have taken place, 33 leading electrical equipment manufacturers have entered into MoU with Powergrid and have got actively involved in this pioneering R & D project. With indigenous R & D and innovations the manufacturers have succeeded in the design, development, testing etc of the main 1200kV equipment like Transformers, Surge Arresters, Circuit Breakers, Instrument Transformers, Transmission Line hardware and accessories etc.

Insulation Co-ordination was the biggest challenge for selection of technical parameters of various equipments like Surge Arrestors, Transformers, Circuit Breakers, and Instrument Transformers etc. The project is scheduled to be commissioned by end December 2010 and slated to create history.

Once commissioned, these test bays and test line shall be used for various field tests/ trials so that the results and feedback can be used for developing field proven equipment as well as to gain initial operational experience. POWERGRID is planning to construct the first 1200kV Transmission Lines between Wardha & Aurangabad (Line length 400 kM, Rs 800 Crores to usher in 1200kV era in the country.

More projects will follow based on the success of Test Station

In conclusion this Indigenous R & D effort in addition to providing help to develop an efficient bulk UHVAC power transfer system in India will also lead to;

- Indigenous availability of equipment & proven technology

- Optimization of cost

- Ease of service.

- Opportunity for Indian Manufacturers to become global leaders in UHVAC technology.

1200kV transmission system initiative will help in the large scale efficient evacuation of power in the 11th and 12th Plan period. The 1200kV system is a step towards overcoming the challenges in the sector such as Right of Way, environmental considerations, optimization of cost, faster project implementation, co-ordinated development of transmission corridor together with other infrastructure, transmission capacity enhancement through upgrading, reduction of losses and integration of emerging technologies. All in all a Win Win situation for all involved in the project.

1200 kV Transformer developed ingeniously by Crompton & Greaves

World’s Highest Voltage Class Transformer, 1200 kV, 333 MVA Single Phase Auto transformer developed successfully by Vijai Electricals Ltd. Hyderabad with Indigenous Technology.

http://www.spml.co.in/mediaroom/2014/Electrical-Monitor-April-2014.pdf

http://www.spml.co.in/mediaroom/2014/Electrical-Monitor-April-2014.pdf

.

.