jamahir

ELITE MEMBER

- Joined

- Jul 9, 2014

- Messages

- 28,132

- Reaction score

- 1

- Country

- Location

‘Gone too far’: Meet the Dutch chips giant that Silicon Valley loves and Biden fears

Christiaan Hetzner

Tue, October 19, 2021, 7:22 PM

ASML may be the most important tech company you’ve never heard of, yet it has the U.S. government running scared for over a year now.

By the start of 2019, the Dutch tech firm pioneered a revolutionary method to manufacture chips known as EUV. Ever since, it's had a complete monopoly on the very machines needed to make the world's most sophisticated microprocessors like the M1 used in Apple's MacBook Pro laptops and iPad Pro tablets.

Only with the aid of the company's groundbreaking EUV photolithography can Intel, Samsung, and Taiwan Semiconductor Manufacturing Company etch the world's smallest transistors, so-called 5 nanometer nodes, onto silicon wafers.

That makes ASML’s machines not just a hit with investors but a strategic necessity for the world's industrial superpowers.

China, for example, desperately wants to buy the semiconductor manufacturing equipment to reduce its dependence on imported chipsets and narrow the technological arms race. Yet Washington continues to pressure the Dutch government to prevent ASML selling to China, precisely at a time when microelectronics are in short supply. The U.S. argues the technology must not be allowed to end up in Beijing's hands because the Chinese could then use the machines to build "dual use" circuitry to gain a military advantage as well as civilian purposes.

It's creating big divisions within Europe and beyond. ASML feels like it's caught in a tug-of-war between Washington and Beijing. Brussels, too, is jumping into the fray.

“Already in 2019, the United States blocked exports of the machines to China, fearing that the Chinese would copy the technology,” Michiel Hoogeveen told Fortune. The conservative Dutch member of the European Parliament, where he sits on the influential trade committee, raised his concerns during a meeting right before key EU summit talks with the U.S. government.

“Gone too far”

The Dutch politician is on board with the Biden Administration—up to a point.

It appears as if ASML has a virtual monopoly on the technology until 2025, when presumably rivals will catch up. For that reason, Hoogeveen favors targeted restrictions on the sale of EUV tech in the name of national security: “These technologies are geopolitical assets we shouldn’t simply hand over to anyone just to make a quick buck.”

Yet Hoogeveen worries President President Joe Biden won't stop there. The administration may seek to expand export controls beyond state-of-the-art lithography machines that harness the properties of extreme ultraviolet (EUV) radiation to include older equipment as well.

The Dutch MEP specifically opposes U.S. efforts to block the sale of argon fluoride (ArF) immersion technology, which uses liquid solutions as a lens to focus electromagnetic light from the deep UV spectrum. Not only are these machines not listed among dual-use goods subject to controls under the international Wassenaar Arrangement, Beijing can already purchase them from Nikon of Japan, ASML’s closest competitor.

“His administration is increasing pressure on ASML to also ban the export of these DUV immersion machines to China,” he explained. “I believe the current administration has gone too far.”

Two-generation advantage

In its final report in March, the National Security Council on Artificial Intelligence chaired by ex-Google CEO Eric Schmidt indeed advised the U.S. government to do just what the Dutch politicians feared. The national security advisers are preaching the U.S. needs to keep China a good two chip generations behind.

Arguing that a multilateral trade body like Wassenaar was too slow to react, and its decisions nonbinding, the NSCAI recommended working with the Dutch and Japanese directly to deny export licenses of both EUV and ArF immersion equipment to Beijing.

"This would slow China’s efforts to domestically produce 7nm or 5nm chips at scale and constrain China’s semiconductor production capability of chips at any node at or below 16nm—which the Commission assesses to be most useful for advanced AI applications—by limiting the capability of Chinese firms to repair or replace existing equipment,“ according to the report.

Asked by Fortune to comment if the U.S. would restrict more semiconductor manufacturing equipment (SME) exports to the PRC, the Department of Commerce and the Office of the U.S. Trade Representative did not respond.

The implications advanced chips pose to national security have only grown following the economic damage wrought by this year’s acute global shortage.

ASML’s chief executive told investors last month countries were waking up to the reality that society cannot function without these complex processors. “They are now finding out that semiconductors are as important, even more important, than oil,” Peter Wennink said.

Originally short for Advanced Semiconductor Materials Lithography, ASML has quietly risen to become the euro area’s second most valuable company by market cap after French luxury giant LVMH, thanks to its monopoly on EUV. The company, which publishes its third-quarter results on Wednesday, reckons its EUV dominance will last a good four more years at least.

Nevertheless, Wennink argues his company needs the business from companies like Shanghai-based Semiconductor Manufacturing International Corporation (SMIC). Even without EUV machines, China is one of his three most voracious consumers, after Taiwan and South Korea.

“If we look at who is investing right now—and it is deep UV immersion, not the leading edge—it’s the Chinese,” he said, citing the need for chips in civilian applications like intelligent driver assistance systems. “As an equipment industry, we need to be shipping to those customers that are actively building fabs.”

Laser precision

Chip lithography follows a simple concept. To create a single transistor, a complex pattern of light is exposed to an area of a photosensitive wafer. This process is repeated until the entire slice of silicon is covered. After which numerous chemicals are applied to remove light resistant areas, creating miniature three dimensional forms—in essence, transistors—only visible with an electron microscope. The shorter the wavelength of the light source, the greater the image resolution and the finer the circuitry elements it can etch.

To manufacture today’s state-of-the-art 5nm-size transistors, the Dutch manufacturer had to develop an even more concentrated light source not naturally occurring on earth. Exciting tin atoms by applying a pulse laser results in electrically charged gas called ionized plasma that emits a wavelength of radiation not even a tenth the size of deep UV light. A series of special mirrors catch, bundle, and focus these photons directly at the silicon wafer to create the 5nm nodes.

Initially ASML had hoped to deliver the first machines to Intel in 2005. The immense complexity meant development was instead mired in a decade of development hell before it succeeded commercializing the technology—a period ASML calls the “Dark Ages of EUV.”

“ASML stepped into that aggressively; others didn’t,” Intel CEO Pat Gelsinger told Fortune. "They’ve earned a tremendous position in the industry as a result, and they really have a unique position now in the supply chain and doing extraordinarily well.”

Asked if he saw the need to build up a strategic competitor in the area of EUV, Gelsinger said he wasn’t concerned about the industry’s dependence on ASML. Nonetheless, he visited the company three times in his first six months on the job and is now prepared to shell out significantly more than €300 million ($350 million) to purchase ASML’s next engineering marvel, due in 2025: a "High NA" machine for its European megafab.

The upcoming EXE:5200 requires precision mirrors one meter in diameter, ground and polished to the point they can position images on the surface of a silicon wafer within 20 picometer. That's a margin of error less than the width of a single helium atom, the smallest element on the periodic table. It could take the Chinese a generation to develop anything similar, the thinking in tech circles goes.

Asked when and if ASML would receive the license to sell its current EUV technology to Beijing, Wennink told investors the issue was entirely out of his hands.

“It’s with the Dutch government, so I’m not going to preempt any decision they will take,” the CEO said. “We’ll have to wait.”

This story was originally featured on Fortune.com

---

Jamahir's comment : The article is good in general but these reducing-transistor-nanometer wars ( to 5nm and less ) are pointless if the end miniaturized product - this 5nm processor - cannot go faster at transistor-level beyond ten gigahertz or so and cannot be able to be used in radiation-filled space and on other worlds. But both these things have been the topic of study and prototyping by NASA which as of 2014 developed a transistor that can run at 460 GHz and be able to tolerate radiation inherently. NASA brought back the idea of the old vacuum tube computer. I quote this article :

@fitpOsitive @ps3linux @Hamartia Antidote @Bilal9 @Naofumi @White and Green with M/S

@ssethii, your expert comment ?

Christiaan Hetzner

Tue, October 19, 2021, 7:22 PM

ASML may be the most important tech company you’ve never heard of, yet it has the U.S. government running scared for over a year now.

By the start of 2019, the Dutch tech firm pioneered a revolutionary method to manufacture chips known as EUV. Ever since, it's had a complete monopoly on the very machines needed to make the world's most sophisticated microprocessors like the M1 used in Apple's MacBook Pro laptops and iPad Pro tablets.

Only with the aid of the company's groundbreaking EUV photolithography can Intel, Samsung, and Taiwan Semiconductor Manufacturing Company etch the world's smallest transistors, so-called 5 nanometer nodes, onto silicon wafers.

That makes ASML’s machines not just a hit with investors but a strategic necessity for the world's industrial superpowers.

China, for example, desperately wants to buy the semiconductor manufacturing equipment to reduce its dependence on imported chipsets and narrow the technological arms race. Yet Washington continues to pressure the Dutch government to prevent ASML selling to China, precisely at a time when microelectronics are in short supply. The U.S. argues the technology must not be allowed to end up in Beijing's hands because the Chinese could then use the machines to build "dual use" circuitry to gain a military advantage as well as civilian purposes.

It's creating big divisions within Europe and beyond. ASML feels like it's caught in a tug-of-war between Washington and Beijing. Brussels, too, is jumping into the fray.

“Already in 2019, the United States blocked exports of the machines to China, fearing that the Chinese would copy the technology,” Michiel Hoogeveen told Fortune. The conservative Dutch member of the European Parliament, where he sits on the influential trade committee, raised his concerns during a meeting right before key EU summit talks with the U.S. government.

“Gone too far”

The Dutch politician is on board with the Biden Administration—up to a point.

It appears as if ASML has a virtual monopoly on the technology until 2025, when presumably rivals will catch up. For that reason, Hoogeveen favors targeted restrictions on the sale of EUV tech in the name of national security: “These technologies are geopolitical assets we shouldn’t simply hand over to anyone just to make a quick buck.”

Yet Hoogeveen worries President President Joe Biden won't stop there. The administration may seek to expand export controls beyond state-of-the-art lithography machines that harness the properties of extreme ultraviolet (EUV) radiation to include older equipment as well.

The Dutch MEP specifically opposes U.S. efforts to block the sale of argon fluoride (ArF) immersion technology, which uses liquid solutions as a lens to focus electromagnetic light from the deep UV spectrum. Not only are these machines not listed among dual-use goods subject to controls under the international Wassenaar Arrangement, Beijing can already purchase them from Nikon of Japan, ASML’s closest competitor.

“His administration is increasing pressure on ASML to also ban the export of these DUV immersion machines to China,” he explained. “I believe the current administration has gone too far.”

Two-generation advantage

In its final report in March, the National Security Council on Artificial Intelligence chaired by ex-Google CEO Eric Schmidt indeed advised the U.S. government to do just what the Dutch politicians feared. The national security advisers are preaching the U.S. needs to keep China a good two chip generations behind.

Arguing that a multilateral trade body like Wassenaar was too slow to react, and its decisions nonbinding, the NSCAI recommended working with the Dutch and Japanese directly to deny export licenses of both EUV and ArF immersion equipment to Beijing.

"This would slow China’s efforts to domestically produce 7nm or 5nm chips at scale and constrain China’s semiconductor production capability of chips at any node at or below 16nm—which the Commission assesses to be most useful for advanced AI applications—by limiting the capability of Chinese firms to repair or replace existing equipment,“ according to the report.

Asked by Fortune to comment if the U.S. would restrict more semiconductor manufacturing equipment (SME) exports to the PRC, the Department of Commerce and the Office of the U.S. Trade Representative did not respond.

The implications advanced chips pose to national security have only grown following the economic damage wrought by this year’s acute global shortage.

ASML’s chief executive told investors last month countries were waking up to the reality that society cannot function without these complex processors. “They are now finding out that semiconductors are as important, even more important, than oil,” Peter Wennink said.

Originally short for Advanced Semiconductor Materials Lithography, ASML has quietly risen to become the euro area’s second most valuable company by market cap after French luxury giant LVMH, thanks to its monopoly on EUV. The company, which publishes its third-quarter results on Wednesday, reckons its EUV dominance will last a good four more years at least.

Nevertheless, Wennink argues his company needs the business from companies like Shanghai-based Semiconductor Manufacturing International Corporation (SMIC). Even without EUV machines, China is one of his three most voracious consumers, after Taiwan and South Korea.

“If we look at who is investing right now—and it is deep UV immersion, not the leading edge—it’s the Chinese,” he said, citing the need for chips in civilian applications like intelligent driver assistance systems. “As an equipment industry, we need to be shipping to those customers that are actively building fabs.”

Laser precision

Chip lithography follows a simple concept. To create a single transistor, a complex pattern of light is exposed to an area of a photosensitive wafer. This process is repeated until the entire slice of silicon is covered. After which numerous chemicals are applied to remove light resistant areas, creating miniature three dimensional forms—in essence, transistors—only visible with an electron microscope. The shorter the wavelength of the light source, the greater the image resolution and the finer the circuitry elements it can etch.

To manufacture today’s state-of-the-art 5nm-size transistors, the Dutch manufacturer had to develop an even more concentrated light source not naturally occurring on earth. Exciting tin atoms by applying a pulse laser results in electrically charged gas called ionized plasma that emits a wavelength of radiation not even a tenth the size of deep UV light. A series of special mirrors catch, bundle, and focus these photons directly at the silicon wafer to create the 5nm nodes.

Initially ASML had hoped to deliver the first machines to Intel in 2005. The immense complexity meant development was instead mired in a decade of development hell before it succeeded commercializing the technology—a period ASML calls the “Dark Ages of EUV.”

“ASML stepped into that aggressively; others didn’t,” Intel CEO Pat Gelsinger told Fortune. "They’ve earned a tremendous position in the industry as a result, and they really have a unique position now in the supply chain and doing extraordinarily well.”

Asked if he saw the need to build up a strategic competitor in the area of EUV, Gelsinger said he wasn’t concerned about the industry’s dependence on ASML. Nonetheless, he visited the company three times in his first six months on the job and is now prepared to shell out significantly more than €300 million ($350 million) to purchase ASML’s next engineering marvel, due in 2025: a "High NA" machine for its European megafab.

The upcoming EXE:5200 requires precision mirrors one meter in diameter, ground and polished to the point they can position images on the surface of a silicon wafer within 20 picometer. That's a margin of error less than the width of a single helium atom, the smallest element on the periodic table. It could take the Chinese a generation to develop anything similar, the thinking in tech circles goes.

Asked when and if ASML would receive the license to sell its current EUV technology to Beijing, Wennink told investors the issue was entirely out of his hands.

“It’s with the Dutch government, so I’m not going to preempt any decision they will take,” the CEO said. “We’ll have to wait.”

This story was originally featured on Fortune.com

---

Jamahir's comment : The article is good in general but these reducing-transistor-nanometer wars ( to 5nm and less ) are pointless if the end miniaturized product - this 5nm processor - cannot go faster at transistor-level beyond ten gigahertz or so and cannot be able to be used in radiation-filled space and on other worlds. But both these things have been the topic of study and prototyping by NASA which as of 2014 developed a transistor that can run at 460 GHz and be able to tolerate radiation inherently. NASA brought back the idea of the old vacuum tube computer. I quote this article :

So the field is open for ASML or any other ambitious company in the world to adopt NASA's research and produce lithography machines that produce processors that are yes small at 5nm or less but can operate at hundreds of gigahertz and are inherently radiation-tolerant.Way back in the salad days of digital computing (the 1940s and ’50s), computers were made of vacuum tubes — big, hot, clunky devices that, when you got right down to it, were essentially glorified light bulbs. This is why early computers like the ENIAC weighed more than 27 tons and consumed more power than a small town. Later, obviously, vacuum tubes would be replaced by probably the greatest invention of all time — the solid-state transistor — which would allow for the creation of smaller, faster, cheaper, and more reliable computers. Fast forward to 2014, though, and the humble CMOS field-effect transistor (FET) is starting to show its age. We’ve pretty much hit the limit on shrinking silicon transistors any further, and they can’t operate at speeds much faster than a few gigahertz. Which is why NASA’s Ames Research Center is going back to the future with its new vacuum transistor — a nanometer-scale vacuum tube that, in early testing, has reached speeds of up to 460GHz.

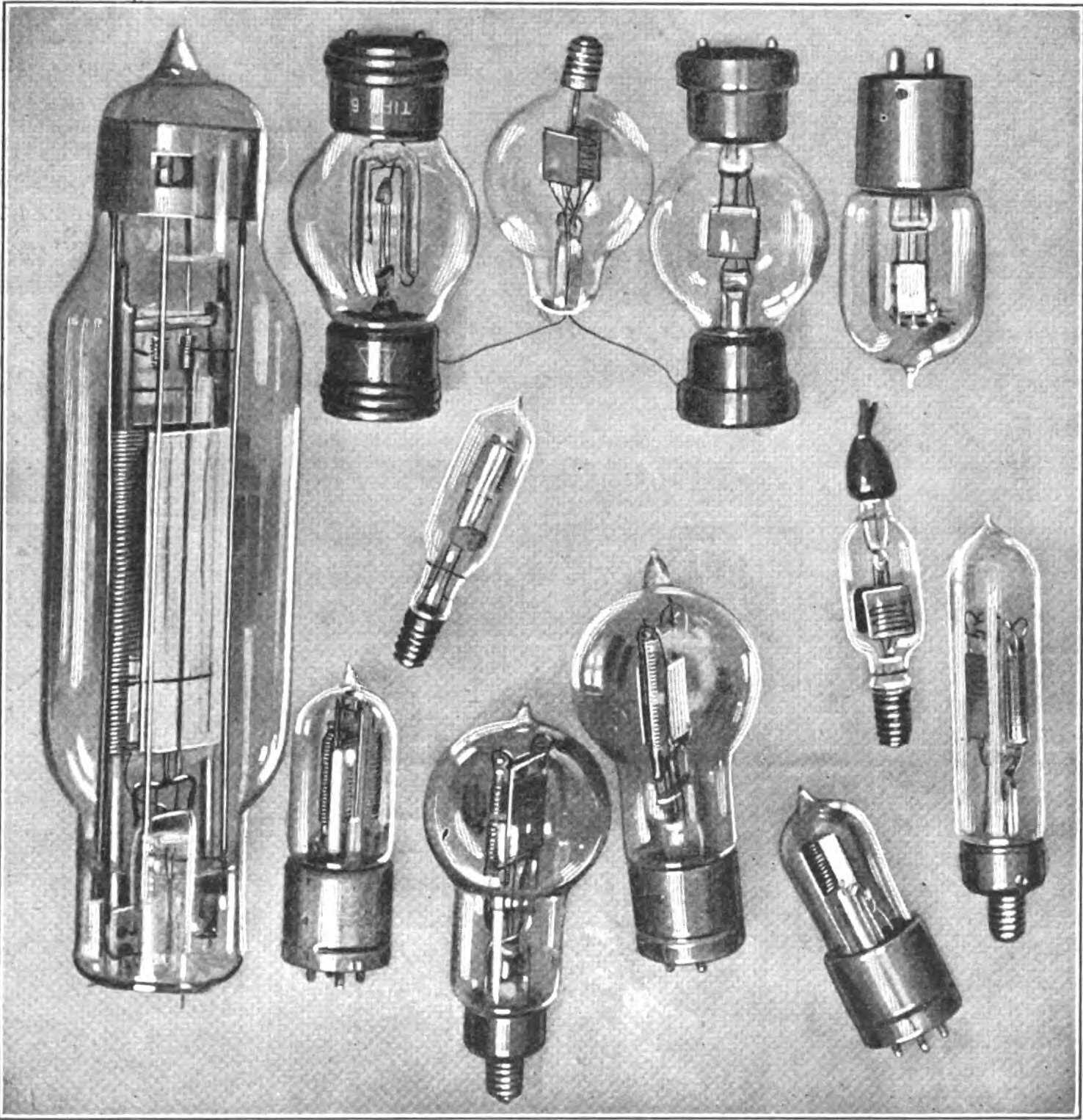

The original vacuum tube triode, the main building block of early computers, consists of three separate elements inside a glass bulb. You have a cathode in the middle, which emits electrons; a grid around the cathode; and an anode around the outside. When a voltage is applied to the grid, electrons flow freely across the vacuum from the cathode to the anode. It is functionally identical to how a modern-day solid-state transistor works (a gate that controls the flow of electricity from source to drain). The main problem, though, was that the cathode had to be heated up by a filament so that it would emit electrons — and where there’s heat, there’s a lot of power consumption and a lot wear and tear. As you may know, it wasn’t unusual for old tube-based computers to break down every few hours whenever a tube burnt out.

So, anyway, the high running costs and frustrations of operating a tube-based computer were eventually assuaged by the discovery of processes that allowed for the cheap and plentiful production of integrated circuits with solid-state MOSFETs. And, in the last 40 years or so, we haven’t looked back. Until now.

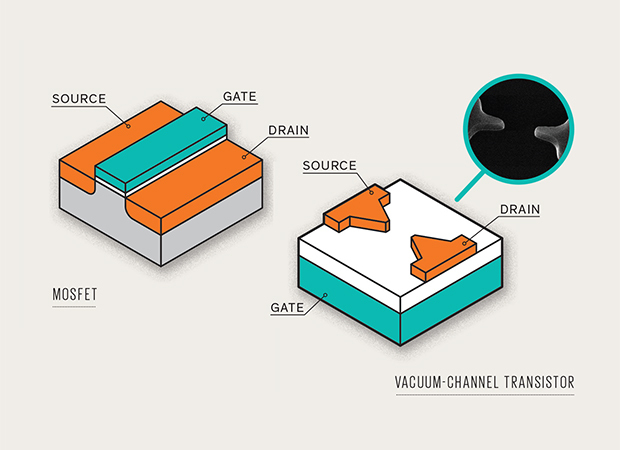

Standard MOSFET vs. vacuum-channel transistor [Image credit: IEEE Spectrum]

NASA’s Ames Research Center has been working on-and-off for many years on the vacuum-channel transistor, which is essentially a vacuum tube that can be fabricated using conventional CMOS techniques. Instead of a gate sitting between the source and drain, there is… nothing. A vacuum. By a method known as field emission, electrons are drawn across the vacuum from the source to the drain when a current is applied to the gate (see diagram). By using field emission rather than the thermionic (hot) electron emission, these vacuum-channel transistors don’t require a heat source. Importantly, they also don’t require a vacuum — instead they use helium (it’s sparse enough that the electrons have almost no chance of bumping into helium atoms while they traverse the few-nanometer gap between source and drain). The electrons also traverse the air gap a lot faster than if they had to pass through the gate electrode.

A collection of early triode vacuum tubes (Click to zoom in)

All in all, these vacuum-channel transistors, crazy as they sound, are surprisingly feasible. They can be fabricated using existing processes. The helium packaging is tougher, but the NASA researchers think that the techniques used to package current microelectromechanical sensors (gyroscopes, accelerometers) should be suitable for their unorthodox transistors as well. In early testing, a vacuum-channel transistor was able to operate at 460GHz — on the order of 10 times faster than a conventional, silicon-based FET (and comparable to the speeds that a graphene transistor might operate at). There’s no word on whether these vacuum-channel transistors will allow for the creation of small, modern audio amplifiers that sound like original tube amps — but maybe!

Moving forward, NASA is faced with the usual stumbling block that all new bleeding-edge technologies face: It’s built a single vacuum-channel transistor in the lab, and now it’s time to try and build large number of them on a single chip. The NASA researchers sound fairly positive about their chances — but really, until they actually get down to it, who knows what issues they might run into? In any case, add vacuum-channel transistors to the rather awesome (and rapidly growing) list of potential methods of pushing past the theoretical limits of silicon.

@fitpOsitive @ps3linux @Hamartia Antidote @Bilal9 @Naofumi @White and Green with M/S

@ssethii, your expert comment ?

Last edited: