How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

APCs,Anti tank tracked & wheeled systems

- Thread starter Manticore

- Start date

Hakan

RETIRED INTL MOD

- Joined

- Feb 9, 2014

- Messages

- 6,274

- Reaction score

- 39

- Country

- Location

Penguin

ELITE MEMBER

- Joined

- Jan 11, 2009

- Messages

- 13,047

- Reaction score

- 56

Like the longbarreled Vena, but also ...

The 120mm AMS

http://defense-update.com/products/a/amsII.htm

http://defense-update.com/products/a/amsII.htm

AMS 120-mm Self-Propelled Mortar System | Military-Today.com

And its Swedish twin barreled cousin AMOS-AMV mortar vehicle

First AMOS vehicles for FDF roll out

The 120mm AMS

AMS 120-mm Self-Propelled Mortar System | Military-Today.com

And its Swedish twin barreled cousin AMOS-AMV mortar vehicle

First AMOS vehicles for FDF roll out

Last edited:

Indus Falcon

SENIOR MEMBER

- Joined

- Mar 4, 2011

- Messages

- 6,910

- Reaction score

- 107

- Country

- Location

GD Unveils Upgraded Piranha

Jun. 18, 2014 - 10:16AM |

By ANDREW CHUTER

The Piranha 3+ unveiled at Eurosatory is heavier, carries more payload and has improved levels of protection. General Dynamics European Land Systems

PARIS— General Dynamics European Land Systems’ (GDELS) latest upgrade of the Piranha 3 armored personnel carrier is market ready and being bid to a number of potential customers, according to a leading company executive.

Briefing reporters at the Eurosatory exhibition Tuesday, Dolf Greuter, the vice president for engineering and technology at GDELS, outlined some of the technical details that make up the new Piranha 3+ given its public debut this week.

Aside from being slightly bigger than the standard Piranha 3, the new machine offers bigger payload, a modular protection system and enhanced power pack, driveline and suspension systems, Greuter said.

The details include a 3-ton increase in gross vehicle weight to 25 tons, and a payload increase of nearly 2 tons to 11 tons. Further growth up to 27 tons is possible.

The vehicle is also available with either hydro-pneumatic or conventional suspension.

Greuter said the vehicle has levels of protection against mines and improvised explosive devices similar to that provided by the much heavier Piranha 5 vehicle.

Upgrades to existing Piranha 3 fleets are available.

Aside from the Piranha 3 improvements, GDELS used Eurosatory to show a number of other recent product innovations.

These included a diesel engine-powered quad bike along with a quad bike bridge and a 4.5-ton air transportable tactical vehicle capable of speeds of 170 kilometers per hour on roads or 90 kilometers per hour off road.

GD Unveils Upgraded Piranha | Defense News | defensenews.com

Jun. 18, 2014 - 10:16AM |

By ANDREW CHUTER

The Piranha 3+ unveiled at Eurosatory is heavier, carries more payload and has improved levels of protection. General Dynamics European Land Systems

PARIS— General Dynamics European Land Systems’ (GDELS) latest upgrade of the Piranha 3 armored personnel carrier is market ready and being bid to a number of potential customers, according to a leading company executive.

Briefing reporters at the Eurosatory exhibition Tuesday, Dolf Greuter, the vice president for engineering and technology at GDELS, outlined some of the technical details that make up the new Piranha 3+ given its public debut this week.

Aside from being slightly bigger than the standard Piranha 3, the new machine offers bigger payload, a modular protection system and enhanced power pack, driveline and suspension systems, Greuter said.

The details include a 3-ton increase in gross vehicle weight to 25 tons, and a payload increase of nearly 2 tons to 11 tons. Further growth up to 27 tons is possible.

The vehicle is also available with either hydro-pneumatic or conventional suspension.

Greuter said the vehicle has levels of protection against mines and improvised explosive devices similar to that provided by the much heavier Piranha 5 vehicle.

Upgrades to existing Piranha 3 fleets are available.

Aside from the Piranha 3 improvements, GDELS used Eurosatory to show a number of other recent product innovations.

These included a diesel engine-powered quad bike along with a quad bike bridge and a 4.5-ton air transportable tactical vehicle capable of speeds of 170 kilometers per hour on roads or 90 kilometers per hour off road.

GD Unveils Upgraded Piranha | Defense News | defensenews.com

Indus Falcon

SENIOR MEMBER

- Joined

- Mar 4, 2011

- Messages

- 6,910

- Reaction score

- 107

- Country

- Location

BadgerIFV manufacturing to start within 24 months

Written by defenceWeb, Thursday, 19 June 2014

Serial production of the Badger infantry fighting vehicle (IFV) for the South African Army will start within the coming 24 months, with the first fully-completed local Badger to roll off production facilities in Lyttelton in late 2016, according to Denel.

The South African National Defence Force (SANDF) and state arms contracting company Armscor placed an order for 238 of the vehicles in November 2013, to be delivered over a ten year period.

At the moment the vehicle is undergoing operational testing and evaluation at various testing grounds in the Northern Cape such as Armscor’s Alkantpan facility and the SA Army’s combat training centre at Lohatla. The SA Army – as the end-user – and Armscor are involved with the process every step of the way to ensure the final design meets their requirements, Denel said.

“The evaluation of the prototype vehicles is in process and we have received very positive feedback from the joint teams responsible for the testing,” said Stephan Burger, the CEO of Denel Land Systems (DLS).

Burger said the locally-designed and produced Badger is the culmination of decades of research, testing and development that produced a mature vehicle which will provide South African soldiers with unrivalled firepower and mobility and maximum armoured protection.

The vehicle’s platform is based on a design from Finnish company Patria, which was modified by DLS to meet local user requirements including landmine protection, manoeuvrability and firepower.

A South African team will soon spend a few months in Finland to participate in the manufacturing of the initial 16 vehicles after which the entire production process will be migrated to South Africa. During this second stage 70% of the vehicle will be produced in South Africa using local skills, manufacturing capacity, defence technology and subcontractors, Denel said.

Burger said the contract will create and retain at least 2 000 jobs in the downstream South African defence industry among local subcontractors as well as 200 direct jobs at Denel Land Systems. These jobs cover a wide spectrum from graduate engineers, system designers and artisans to skilled and semi-skilled workers.

“The programme makes a decisive contribution to meet the country industrial objectives with regards to skills development, advanced manufacturing and job creation,” he said.

The Programme Manager, Avishkar Govender, said the modular infantry system has been developed by Denel Land System in five variants, namely Command, Section, Mortar, Missile and Fire Support derivatives. The common turret structure, fitted with different weapon modules as well as a common platform, with variant specific fits will simplify the logistic support and reduce the cost of through-life support.

The Badger variants are equipped with various weapon systems. The main weapon system, used on the Section and Fire Support Variants, is the 30 mm externally-driven cam-operated cannon. This was developed by DLS, along with the 30 mm ammunition produced by Denel’s PMP division.

For the Mortar Variant, a 60 mm breech-loading long-range mortar was developed by DLS, along with 60 mm long-range NATO ammunition while the Ingwe anti-tank missile system, developed by Denel Dynamics, is used on the Missile Variant.

Burger said the Badger confirms Denel’s position as South Africa’s premier producer of world-class defence products and systems and a strategic partner of the SANDF.

The Badger project has already resulted in Malaysia ordering R3.5 billion worth of turrets and weapons from Denel, developed for the Badger.

The cost of the Badger programme amounts to R15.4 billion, up from the original estimate of R8 billion, according to Defence and Military Veterans Minister Nosiviwe Mapisa-Nqakula.

The order for the 238 vehicles was trimmed down from 264 due to funding constraints. “The total requirement of 264 vehicles as per the SA Army requirements was acknowledged, but because of available funds for the project, approval for 238 vehicles was granted to remain within the allocated funds,” the Minister said in February.

Military analyst Helmoed Heitman told Business Day the cost increase could be due to inflation as the original project was mooted some five years ago. The current contract also included spares, an item not in the original estimate.

The full fleet of Badgers will replace the Army’s ageing Ratels when deliveries conclude. Last year Denel said the first Badger would roll of its production facilities in October 15 but this timetable has slipped.

Badger IFV manufacturing to start within 24 months | defenceWeb

Written by defenceWeb, Thursday, 19 June 2014

Serial production of the Badger infantry fighting vehicle (IFV) for the South African Army will start within the coming 24 months, with the first fully-completed local Badger to roll off production facilities in Lyttelton in late 2016, according to Denel.

The South African National Defence Force (SANDF) and state arms contracting company Armscor placed an order for 238 of the vehicles in November 2013, to be delivered over a ten year period.

At the moment the vehicle is undergoing operational testing and evaluation at various testing grounds in the Northern Cape such as Armscor’s Alkantpan facility and the SA Army’s combat training centre at Lohatla. The SA Army – as the end-user – and Armscor are involved with the process every step of the way to ensure the final design meets their requirements, Denel said.

“The evaluation of the prototype vehicles is in process and we have received very positive feedback from the joint teams responsible for the testing,” said Stephan Burger, the CEO of Denel Land Systems (DLS).

Burger said the locally-designed and produced Badger is the culmination of decades of research, testing and development that produced a mature vehicle which will provide South African soldiers with unrivalled firepower and mobility and maximum armoured protection.

The vehicle’s platform is based on a design from Finnish company Patria, which was modified by DLS to meet local user requirements including landmine protection, manoeuvrability and firepower.

A South African team will soon spend a few months in Finland to participate in the manufacturing of the initial 16 vehicles after which the entire production process will be migrated to South Africa. During this second stage 70% of the vehicle will be produced in South Africa using local skills, manufacturing capacity, defence technology and subcontractors, Denel said.

Burger said the contract will create and retain at least 2 000 jobs in the downstream South African defence industry among local subcontractors as well as 200 direct jobs at Denel Land Systems. These jobs cover a wide spectrum from graduate engineers, system designers and artisans to skilled and semi-skilled workers.

“The programme makes a decisive contribution to meet the country industrial objectives with regards to skills development, advanced manufacturing and job creation,” he said.

The Programme Manager, Avishkar Govender, said the modular infantry system has been developed by Denel Land System in five variants, namely Command, Section, Mortar, Missile and Fire Support derivatives. The common turret structure, fitted with different weapon modules as well as a common platform, with variant specific fits will simplify the logistic support and reduce the cost of through-life support.

The Badger variants are equipped with various weapon systems. The main weapon system, used on the Section and Fire Support Variants, is the 30 mm externally-driven cam-operated cannon. This was developed by DLS, along with the 30 mm ammunition produced by Denel’s PMP division.

For the Mortar Variant, a 60 mm breech-loading long-range mortar was developed by DLS, along with 60 mm long-range NATO ammunition while the Ingwe anti-tank missile system, developed by Denel Dynamics, is used on the Missile Variant.

Burger said the Badger confirms Denel’s position as South Africa’s premier producer of world-class defence products and systems and a strategic partner of the SANDF.

The Badger project has already resulted in Malaysia ordering R3.5 billion worth of turrets and weapons from Denel, developed for the Badger.

The cost of the Badger programme amounts to R15.4 billion, up from the original estimate of R8 billion, according to Defence and Military Veterans Minister Nosiviwe Mapisa-Nqakula.

The order for the 238 vehicles was trimmed down from 264 due to funding constraints. “The total requirement of 264 vehicles as per the SA Army requirements was acknowledged, but because of available funds for the project, approval for 238 vehicles was granted to remain within the allocated funds,” the Minister said in February.

Military analyst Helmoed Heitman told Business Day the cost increase could be due to inflation as the original project was mooted some five years ago. The current contract also included spares, an item not in the original estimate.

The full fleet of Badgers will replace the Army’s ageing Ratels when deliveries conclude. Last year Denel said the first Badger would roll of its production facilities in October 15 but this timetable has slipped.

Badger IFV manufacturing to start within 24 months | defenceWeb

Indus Falcon

SENIOR MEMBER

- Joined

- Mar 4, 2011

- Messages

- 6,910

- Reaction score

- 107

- Country

- Location

BAE, Goriziane Strike Deal on Support of Italian Bv206 Vehicles

Jun. 19, 2014

By ANDREW CHUTER

Under an agreement with BAE Systems, the Goriziane Group will be the only authorized partner to support the Italian fleet of Bv206 vehicles. (BAE Systems)

PARIS— BAE Systems and the Goriziane Group have firmed up a memorandum of agreement to jointly provide support and services for Italian military users of the Bv206 and Bv206S all-terrain vehicles.

The agreement makes Goriziane the sole partner authorized to conduct support and services on the Italian fleet, BAE officials said at the Eurosatory show here Thursday.

The Truppe Alpini have been users of the Bv206 for years and deployed with the protected 206S version during the Italian mission in Afghanistan. Some 300 of the Swedish-built vehicles are in military service in Italy.

The two companies have previously collaborated in providing service, support and overhaul for the Italian fleet of BAE AAV7 amphibious vehicles.

Goriziane was founded in 1945 as a family-run workshop for the overhaul of motor vehicles and work-yard machines and has built up a position as an established supplier to the Italian Ministry of Defense.

BAE, Goriziane Strike Deal on Support of Italian Bv206 Vehicles | Defense News | defensenews.com

Jun. 19, 2014

By ANDREW CHUTER

Under an agreement with BAE Systems, the Goriziane Group will be the only authorized partner to support the Italian fleet of Bv206 vehicles. (BAE Systems)

PARIS— BAE Systems and the Goriziane Group have firmed up a memorandum of agreement to jointly provide support and services for Italian military users of the Bv206 and Bv206S all-terrain vehicles.

The agreement makes Goriziane the sole partner authorized to conduct support and services on the Italian fleet, BAE officials said at the Eurosatory show here Thursday.

The Truppe Alpini have been users of the Bv206 for years and deployed with the protected 206S version during the Italian mission in Afghanistan. Some 300 of the Swedish-built vehicles are in military service in Italy.

The two companies have previously collaborated in providing service, support and overhaul for the Italian fleet of BAE AAV7 amphibious vehicles.

Goriziane was founded in 1945 as a family-run workshop for the overhaul of motor vehicles and work-yard machines and has built up a position as an established supplier to the Italian Ministry of Defense.

BAE, Goriziane Strike Deal on Support of Italian Bv206 Vehicles | Defense News | defensenews.com

Indus Falcon

SENIOR MEMBER

- Joined

- Mar 4, 2011

- Messages

- 6,910

- Reaction score

- 107

- Country

- Location

Driverless Technology Begins To Mature

Jun. 19, 2014

By ANDREW CHUTER

Oshkosh has demonstrated an autonomous vehicle system to steer an M-ATV vehicle. (William Kapinski/Oshkosh)

PARIS— Oshkosh has given the first live, trade show demonstration of its TerraMax autonomous vehicle system, using it to steer an M-ATV vehicle and a mine roller round the demonstration area at Eurosatory.

After 10 years of development, teamed with the US Marines and Army, the system will be offered as a way to reduce personnel in dangerous convoys, and officials said they hoped it would be deployed within three to five years.

The US vehicle builder was not alone in using the demonstration arena to show its progress toward a production standard driverless system.

Ruag of Switzerland, with a system installed in a General Dynamics European Land Systems Eagle protected mobility vehicle, also demonstrated its capabilities on the Eurosatory track .

Lockheed Martin didn’t have a vehicle on the test track but it briefed reporters on the increasingly complex testing it has been doing on its autonomous mobility applique system (AMAS) program for the US Marines and Army.

The system is primarily being developed to allow fully autonomous convoys to operate even in complex urban areas.

Driverless vehicles are not new. The Israelis already employ the technology on vehicles and for others Afghanistan has been a proving ground for remote systems.

Example: The British Army used a remotely controlled Land Rover rapidly developed by local company MIRA to undertake route clearance duties to combat roadside bombs.

The technology remains in its infancy but progress is propelling it toward production in the next few years.

The Oshkosh system has already autonomously driven a vehicle 100 miles, passing a series of waypoints during a Defense Advanced Research Projects Agency Challenge in the US.

The system could be used in concert with manned vehicles for convoys, route clearance and missions to defeat improvised explosive devices, said John Urias, president of Oshkosh Defense.

The system uses radar, lidar, video and GPS mapping, although Oshkosh claims the system can pilot a vehicle for 18 miles without GPS, relying on inertial measurement unit technology.

Designed to pilot vehicles at a convoy speed of 35 miles per hour, the system is designed to stop the vehicle if it sees something it does not understand, at which point a remote operator can intervene. A driver can also enter the vehicle and take over the controls if required.

A spokeswoman said the system has proved easy to master. “Six Marines trained for three days, after which each one was comfortable operating three vehicles at the same time,” said Jennifer Christiansen.

The system’s autonomy gave it an advantage over remote controlled vehicles, Christiansen said.

“They are dramatically different technologies,” she said. “Autonomy brings force multiplication into the equation.”

Ruag, meanwhile, has taken a halfway house approach to autonomy compared with its US rival, and reckons what it calls “supervised autonomy” is about as far as it can currently push the technology boundaries.

“We are not there yet with full autonomy,” Vero business development manager Ferdinand Zoller said during a briefing with reporters at the show Wednesday.

But driverless systems have their Achilles’ heel. Experts say the systems could be vulnerable to asymmetric attack.

An opponent with a $5 can of spray paint or a roll of aluminum baking foil could mask sensors or even steal them, said one industry executive.

Ruag has fitted a vertical take-off UAV built by Estonian company Eli to the roof of the vehicle that can be remotely launched to give the driver additional cues and a limited reconnaissance capability.

“While a driver can’t see round the corner with the vehicle’s cameras, he can see everything from above,” Zoller said.

The executive said Ruag had looked at using Sky Sapience’s tethered hovering reconnaissance platform to provide the driver cues and other capabilities but had no intention to integrate the Israeli developed system at this time.

The Vero system being developed by Ruag is scheduled to get its production release in 2016, Zoller told reporters.

The system is fitted to the Eagle armored vehicle but could be fitted to any number of similar vehicles.

Zoller said the company is already testing alternative vehicle applications but declined to name them. An existing vehicle could be converted within two days, he said.

Used in conjunction with Ruag software, the cameras and sensors fitted as part of the Vero system would allow any vehicle equipped with the technology to learn a route to drive or, alternatively, the route can be programmed using an interface.

The vehicle will then drive the route at the request of its operator, constantly scanning the area for obstacles and threats and relaying that information back to a control station.

The vehicle also can be operated simply using remote control.

Ruag showed the adapted Eagle’s capability on the demonstration area with a driver installed in a control room at its Eurosatory stand over half a mile from the track.

Zoller said the Vero had been tested out to a distance of 1.6 kilometers between vehicle and control room antenna but the distance could be increased by adding a relay station.

Driverless Technology Begins To Mature | Defense News | defensenews.com

Jun. 19, 2014

By ANDREW CHUTER

Oshkosh has demonstrated an autonomous vehicle system to steer an M-ATV vehicle. (William Kapinski/Oshkosh)

PARIS— Oshkosh has given the first live, trade show demonstration of its TerraMax autonomous vehicle system, using it to steer an M-ATV vehicle and a mine roller round the demonstration area at Eurosatory.

After 10 years of development, teamed with the US Marines and Army, the system will be offered as a way to reduce personnel in dangerous convoys, and officials said they hoped it would be deployed within three to five years.

The US vehicle builder was not alone in using the demonstration arena to show its progress toward a production standard driverless system.

Ruag of Switzerland, with a system installed in a General Dynamics European Land Systems Eagle protected mobility vehicle, also demonstrated its capabilities on the Eurosatory track .

Lockheed Martin didn’t have a vehicle on the test track but it briefed reporters on the increasingly complex testing it has been doing on its autonomous mobility applique system (AMAS) program for the US Marines and Army.

The system is primarily being developed to allow fully autonomous convoys to operate even in complex urban areas.

Driverless vehicles are not new. The Israelis already employ the technology on vehicles and for others Afghanistan has been a proving ground for remote systems.

Example: The British Army used a remotely controlled Land Rover rapidly developed by local company MIRA to undertake route clearance duties to combat roadside bombs.

The technology remains in its infancy but progress is propelling it toward production in the next few years.

The Oshkosh system has already autonomously driven a vehicle 100 miles, passing a series of waypoints during a Defense Advanced Research Projects Agency Challenge in the US.

The system could be used in concert with manned vehicles for convoys, route clearance and missions to defeat improvised explosive devices, said John Urias, president of Oshkosh Defense.

The system uses radar, lidar, video and GPS mapping, although Oshkosh claims the system can pilot a vehicle for 18 miles without GPS, relying on inertial measurement unit technology.

Designed to pilot vehicles at a convoy speed of 35 miles per hour, the system is designed to stop the vehicle if it sees something it does not understand, at which point a remote operator can intervene. A driver can also enter the vehicle and take over the controls if required.

A spokeswoman said the system has proved easy to master. “Six Marines trained for three days, after which each one was comfortable operating three vehicles at the same time,” said Jennifer Christiansen.

The system’s autonomy gave it an advantage over remote controlled vehicles, Christiansen said.

“They are dramatically different technologies,” she said. “Autonomy brings force multiplication into the equation.”

Ruag, meanwhile, has taken a halfway house approach to autonomy compared with its US rival, and reckons what it calls “supervised autonomy” is about as far as it can currently push the technology boundaries.

“We are not there yet with full autonomy,” Vero business development manager Ferdinand Zoller said during a briefing with reporters at the show Wednesday.

But driverless systems have their Achilles’ heel. Experts say the systems could be vulnerable to asymmetric attack.

An opponent with a $5 can of spray paint or a roll of aluminum baking foil could mask sensors or even steal them, said one industry executive.

Ruag has fitted a vertical take-off UAV built by Estonian company Eli to the roof of the vehicle that can be remotely launched to give the driver additional cues and a limited reconnaissance capability.

“While a driver can’t see round the corner with the vehicle’s cameras, he can see everything from above,” Zoller said.

The executive said Ruag had looked at using Sky Sapience’s tethered hovering reconnaissance platform to provide the driver cues and other capabilities but had no intention to integrate the Israeli developed system at this time.

The Vero system being developed by Ruag is scheduled to get its production release in 2016, Zoller told reporters.

The system is fitted to the Eagle armored vehicle but could be fitted to any number of similar vehicles.

Zoller said the company is already testing alternative vehicle applications but declined to name them. An existing vehicle could be converted within two days, he said.

Used in conjunction with Ruag software, the cameras and sensors fitted as part of the Vero system would allow any vehicle equipped with the technology to learn a route to drive or, alternatively, the route can be programmed using an interface.

The vehicle will then drive the route at the request of its operator, constantly scanning the area for obstacles and threats and relaying that information back to a control station.

The vehicle also can be operated simply using remote control.

Ruag showed the adapted Eagle’s capability on the demonstration area with a driver installed in a control room at its Eurosatory stand over half a mile from the track.

Zoller said the Vero had been tested out to a distance of 1.6 kilometers between vehicle and control room antenna but the distance could be increased by adding a relay station.

Driverless Technology Begins To Mature | Defense News | defensenews.com

Indus Falcon

SENIOR MEMBER

- Joined

- Mar 4, 2011

- Messages

- 6,910

- Reaction score

- 107

- Country

- Location

French Scorpion Vehicle Deal Takes Shape

Jun. 21, 2014 By PIERRE TRAN

PARIS— French Army planners, procurement officials and a three-company group are working on terms and conditions of a draft contract aimed at launching a €5 billion (US $6.8 billion) Scorpion equipment modernization this year, the biggest European program for land weapons, a company executive and defense official said.

The Army and industry dearly hope the program will go ahead, as development and production of a troop carrier and a medium tank are seen as crucial for business and operational needs.

“It’s a holistic contract that covers all aspects from the cradle to the foxhole,” the executive said.

Nexter, Renault Trucks Defense (RTD) and Thales lead an all-French cooperative team selected by the Direction Générale de l’Armement (DGA) procurement office to bid exclusively for the véhicule blindé multirole (VBMR), a troop carrier, and engin blindé de reconnaissance et de combat (EBRC), a wheeled medium tank.

The industry team is in negotiations on the terms and conditions of the planned contract, covering the budget, timetable, specifications, production and logistical support, the executive said.

Some €2 billion out of the €5 billion Scorpion budget has been earmarked for 2,080 VBMRs, while the budget for the 248 EBRC tanks is closely held. A collective term — EBMR — covers the two vehicle programs, which are intended to have a high level of common equipment.

“The launch is a great opportunity for the French companies and their supply network of small and medium-sized enterprises to develop two new families of modern vehicles, the VBMR and EBRC, with their equipment,” Defense Minister Jean-Yves Le Drian said on June 16 at Eurosatory. The land systems and security trade show closed June 20.

The Scorpion program includes modernization of the Leclerc heavy tank and an information network for the battle group.

The corporate team submitted a first bid on the EBMR vehicles in February, which set a “rough order of magnitude,” the executive said.

That baseline allowed the talks to go ahead with the DGA and Army, as the three parties seek to agree on the vehicles, weapons, an onboard combat information system named système d’information et de combat Scorpion, and squeeze them all into a tight budget.

“The timetable is not clear but industry expects — fingers crossed — a contract signing this autumn,” the executive said.

James Tinsley, managing director at consultancy Avascent, said the terms and conditions would be related to numbers, funding and break points. If there were a cut in production or if there were changes to be made, funding would be restructured.

“That is a very critical discussion,” he said. “They need mechanisms to change terms for industry.”

A first delivery of the combat information system is due in 2016, and a first batch of 92 VBMRs will start rolling off the production line in 2018, a defense official said. The contract will include initial support, including debugging the first batch.

The first EBRC is due for delivery in 2020, with a total 248 units, the official said.

However, the DGA is unable to sign any orders as there is deep uncertainty while the Economy Ministry looks to slash spending, the official said.

Renault Trucks Defense, a Volvo unit, displayed at Eurosatory its BMX 01 demonstration vehicle for the VBMR. Nexter had built its BMX 02 vehicle. The DGA had commissioned the two companies to build the demonstrators for the armored personnel carrier. Under the cooperative agreement, Nexter will work on the hull, RTD the engine and driveline, and Thales will supply the electronics and network.

The Army is clear about the requirement.

“We know what we want; everything is specified,” said Army Col. Rémy Cadapeaud, Scorpion program officer.

The EBRC specification includes the architecture, six-wheel drive, level of protection, 7.62mm remote machine gun, 40mm cannon, missile moyenne portée (or medium-range missile), vehicle electronics and combat information system.

MBDA builds the anti-tank missile and CTA International, a joint venture between BAE Systems and Nexter, makes the 40mm gun. Two crew members will be in the turret and one in the hull.

The information system is “the brain of Scorpion,” a second officer said at Eurosatory.

The vehicles fitted with the combat information system, delivered on a single communications network, will connect “from the bottom to the top,” Cadapeaud said.

The priority is an information system for “soldiers facing the enemy, not the chiefs safe in their trucks, safe from the enemy,” he said. “We want the enemy to say, ‘these are strange soldiers, they have a new information system that gives them advantages, they know things we don’t, they can anticipate.’ ”

Lessons learned from the field have fed the requirement for an “augmented reality,” a capability that allows crews to track a friendly blue force equipped with GPS on the screen and avoid firing on them.

“That’s new for land forces. The Air Force and Army aviation have that capability,” Cadapeaud said.

An augmented reality is intended “to accelerate the decision-making, to understand, know everything, and know what you know is right, at the right time and right place. You want to play chess and see everything on the table. We want to know everything.”

The planners see vehicle electronics as essential, “keeping soldiers and chiefs in the loop, connecting system to system, sensors, other vehicles, and detection,” he said. “You plug in all your systems and subsystems with standard interfaces over 40 to 50 years, at a very low cost.”

The electronics onboard will also deliver a training simulation, so the service can train troops wherever a VBMR is to be found. The system can also be used to prepare for the mission.

The Army expects some 1,700 heavy and 300 light VBMR units, both four-wheeled and six-wheeled.

Planners asked for the engine to be set in the front of the vehicle and opened up the hull interior for the three crew and eight troops to be in the same open space. The design is modular, so the vehicle can by equipped for specific missions by plugging in kits.

There are three versions: troop carrier, 120mm mortar carrier with an open roof, and medical. That compares to the 34 for the véhicule avant blindé, the present troop carrier.

Both the EBRC and VBMR will have remote control weapons. The former will carry the MMP on the turret, while troops can stow the anti-tank weapon inside the VBMR.

The VBMR will be fitted for the Sagem Felin soldier’s gear, be air conditioned, and the medical version will have added air cooling.

Thales will deliver the electronics, integrate voice, video, electro-optronics, radar and data. The company won the contract for the Contact software defined radio in the last days of the previous administration in 2012.

Sagem will supply some of the electro-optronics on the vehicles.

The VBMR will replace the venerable véhicule avant blindé, which is some 40 years old. The former will weigh 22 tons compared to the latter’s 18.

Scorpion is important for Nexter, said François Lureau of consultancy EuroFLconsult. The VBMR and EBRC vehicles are the main part of the program, he said.

Exports are crucial to the company as the last véhicule blindé de combat d’infanterie is delivered next year to the French Army, he said.

A “lack of visibility” leads to a lower attractiveness of the French military vehicle market, which hurts Nexter as the company is still highly dependent on domestic orders and wholly state-owned, Hélène Masson, senior research fellow at Fondation de Récherche Stratégique, wrote in the first publication of the think tank’s Défense & Industries report.

On the price of the EBRC vehicle, Cadapeaud said, “Not so much.”

The key point is not the unit price but its development, and maintenance support of the vehicle. “You can have an expensive vehicle, but cheap to maintain, or a low price vehicle and expensive to sustain — that’s not good.

“We must have a sustainable system. And we will have it,” Cadapeaud said. “The key point is the price. It won’t be their price, it will be our price.”

The Army works in an integrated way with the DGA, expressing the military need to the procurement office, which discusses with industry to see the price and technology consequences, he said

“We launch when ready, at the price we can afford,” he said.

The Army adopted a Scorpion branding strategy to protect acquisition from death by a thousand cuts.

A parliamentary official said that given a lack of clarity on the defense budget, it would have been safer for the Army to focus on smaller individual programs rather than package them all up under the Scorpion mega-contract.

The service’s idea was to build the equivalent of an aircraft carrier, too big to cancel, said François Lureau at consultancy EuroFLconsult.

In June’s edition of the Army’s glossy in-house magazine, Armées d’Aujourd’hui, the special feature on the Scorpion program has a box story spelling out the decision by the high-level ministerial investment committee, chaired by the minister, to go ahead with an order for the land weapons program

French Scorpion Vehicle Deal Takes Shape | Defense News | defensenews.com

Jun. 21, 2014 By PIERRE TRAN

PARIS— French Army planners, procurement officials and a three-company group are working on terms and conditions of a draft contract aimed at launching a €5 billion (US $6.8 billion) Scorpion equipment modernization this year, the biggest European program for land weapons, a company executive and defense official said.

The Army and industry dearly hope the program will go ahead, as development and production of a troop carrier and a medium tank are seen as crucial for business and operational needs.

“It’s a holistic contract that covers all aspects from the cradle to the foxhole,” the executive said.

Nexter, Renault Trucks Defense (RTD) and Thales lead an all-French cooperative team selected by the Direction Générale de l’Armement (DGA) procurement office to bid exclusively for the véhicule blindé multirole (VBMR), a troop carrier, and engin blindé de reconnaissance et de combat (EBRC), a wheeled medium tank.

The industry team is in negotiations on the terms and conditions of the planned contract, covering the budget, timetable, specifications, production and logistical support, the executive said.

Some €2 billion out of the €5 billion Scorpion budget has been earmarked for 2,080 VBMRs, while the budget for the 248 EBRC tanks is closely held. A collective term — EBMR — covers the two vehicle programs, which are intended to have a high level of common equipment.

“The launch is a great opportunity for the French companies and their supply network of small and medium-sized enterprises to develop two new families of modern vehicles, the VBMR and EBRC, with their equipment,” Defense Minister Jean-Yves Le Drian said on June 16 at Eurosatory. The land systems and security trade show closed June 20.

The Scorpion program includes modernization of the Leclerc heavy tank and an information network for the battle group.

The corporate team submitted a first bid on the EBMR vehicles in February, which set a “rough order of magnitude,” the executive said.

That baseline allowed the talks to go ahead with the DGA and Army, as the three parties seek to agree on the vehicles, weapons, an onboard combat information system named système d’information et de combat Scorpion, and squeeze them all into a tight budget.

“The timetable is not clear but industry expects — fingers crossed — a contract signing this autumn,” the executive said.

James Tinsley, managing director at consultancy Avascent, said the terms and conditions would be related to numbers, funding and break points. If there were a cut in production or if there were changes to be made, funding would be restructured.

“That is a very critical discussion,” he said. “They need mechanisms to change terms for industry.”

A first delivery of the combat information system is due in 2016, and a first batch of 92 VBMRs will start rolling off the production line in 2018, a defense official said. The contract will include initial support, including debugging the first batch.

The first EBRC is due for delivery in 2020, with a total 248 units, the official said.

However, the DGA is unable to sign any orders as there is deep uncertainty while the Economy Ministry looks to slash spending, the official said.

Renault Trucks Defense, a Volvo unit, displayed at Eurosatory its BMX 01 demonstration vehicle for the VBMR. Nexter had built its BMX 02 vehicle. The DGA had commissioned the two companies to build the demonstrators for the armored personnel carrier. Under the cooperative agreement, Nexter will work on the hull, RTD the engine and driveline, and Thales will supply the electronics and network.

The Army is clear about the requirement.

“We know what we want; everything is specified,” said Army Col. Rémy Cadapeaud, Scorpion program officer.

The EBRC specification includes the architecture, six-wheel drive, level of protection, 7.62mm remote machine gun, 40mm cannon, missile moyenne portée (or medium-range missile), vehicle electronics and combat information system.

MBDA builds the anti-tank missile and CTA International, a joint venture between BAE Systems and Nexter, makes the 40mm gun. Two crew members will be in the turret and one in the hull.

The information system is “the brain of Scorpion,” a second officer said at Eurosatory.

The vehicles fitted with the combat information system, delivered on a single communications network, will connect “from the bottom to the top,” Cadapeaud said.

The priority is an information system for “soldiers facing the enemy, not the chiefs safe in their trucks, safe from the enemy,” he said. “We want the enemy to say, ‘these are strange soldiers, they have a new information system that gives them advantages, they know things we don’t, they can anticipate.’ ”

Lessons learned from the field have fed the requirement for an “augmented reality,” a capability that allows crews to track a friendly blue force equipped with GPS on the screen and avoid firing on them.

“That’s new for land forces. The Air Force and Army aviation have that capability,” Cadapeaud said.

An augmented reality is intended “to accelerate the decision-making, to understand, know everything, and know what you know is right, at the right time and right place. You want to play chess and see everything on the table. We want to know everything.”

The planners see vehicle electronics as essential, “keeping soldiers and chiefs in the loop, connecting system to system, sensors, other vehicles, and detection,” he said. “You plug in all your systems and subsystems with standard interfaces over 40 to 50 years, at a very low cost.”

The electronics onboard will also deliver a training simulation, so the service can train troops wherever a VBMR is to be found. The system can also be used to prepare for the mission.

The Army expects some 1,700 heavy and 300 light VBMR units, both four-wheeled and six-wheeled.

Planners asked for the engine to be set in the front of the vehicle and opened up the hull interior for the three crew and eight troops to be in the same open space. The design is modular, so the vehicle can by equipped for specific missions by plugging in kits.

There are three versions: troop carrier, 120mm mortar carrier with an open roof, and medical. That compares to the 34 for the véhicule avant blindé, the present troop carrier.

Both the EBRC and VBMR will have remote control weapons. The former will carry the MMP on the turret, while troops can stow the anti-tank weapon inside the VBMR.

The VBMR will be fitted for the Sagem Felin soldier’s gear, be air conditioned, and the medical version will have added air cooling.

Thales will deliver the electronics, integrate voice, video, electro-optronics, radar and data. The company won the contract for the Contact software defined radio in the last days of the previous administration in 2012.

Sagem will supply some of the electro-optronics on the vehicles.

The VBMR will replace the venerable véhicule avant blindé, which is some 40 years old. The former will weigh 22 tons compared to the latter’s 18.

Scorpion is important for Nexter, said François Lureau of consultancy EuroFLconsult. The VBMR and EBRC vehicles are the main part of the program, he said.

Exports are crucial to the company as the last véhicule blindé de combat d’infanterie is delivered next year to the French Army, he said.

A “lack of visibility” leads to a lower attractiveness of the French military vehicle market, which hurts Nexter as the company is still highly dependent on domestic orders and wholly state-owned, Hélène Masson, senior research fellow at Fondation de Récherche Stratégique, wrote in the first publication of the think tank’s Défense & Industries report.

On the price of the EBRC vehicle, Cadapeaud said, “Not so much.”

The key point is not the unit price but its development, and maintenance support of the vehicle. “You can have an expensive vehicle, but cheap to maintain, or a low price vehicle and expensive to sustain — that’s not good.

“We must have a sustainable system. And we will have it,” Cadapeaud said. “The key point is the price. It won’t be their price, it will be our price.”

The Army works in an integrated way with the DGA, expressing the military need to the procurement office, which discusses with industry to see the price and technology consequences, he said

“We launch when ready, at the price we can afford,” he said.

The Army adopted a Scorpion branding strategy to protect acquisition from death by a thousand cuts.

A parliamentary official said that given a lack of clarity on the defense budget, it would have been safer for the Army to focus on smaller individual programs rather than package them all up under the Scorpion mega-contract.

The service’s idea was to build the equivalent of an aircraft carrier, too big to cancel, said François Lureau at consultancy EuroFLconsult.

In June’s edition of the Army’s glossy in-house magazine, Armées d’Aujourd’hui, the special feature on the Scorpion program has a box story spelling out the decision by the high-level ministerial investment committee, chaired by the minister, to go ahead with an order for the land weapons program

French Scorpion Vehicle Deal Takes Shape | Defense News | defensenews.com

Indus Falcon

SENIOR MEMBER

- Joined

- Mar 4, 2011

- Messages

- 6,910

- Reaction score

- 107

- Country

- Location

Land Panther: Germany’s Tracked Puma IFV

Jun 21, 201418:14 UTC by Defense Industry Daily staff

Heat and cold trials done, formal delivery coming next; More changes will be needed after acceptance; Article reformatted; Additional Readings sections updated.

June 12/14: Heat Trials.Rheinmetall announces that its Puma has successfully completed firing and mobility trials in the UAE, in temperatures that ranged between 35-50C in the shade. The MK30-2/ABM automatic 30mm cannon and the MG4 7.62 machine gun both performed well in stationary and moving firing trials, the air conditioning system held up well and efficiently, and mobility trials went well in sand dunes, steep loose-surface tracks, and a rocky desert streambed.

With the completion of cold and hot-weather trials, the IFV is about ready for acceptance. Sources: Rheinmetall, “Puma stands up to heat and sand”.

Sept 17/13: Testing.German media report that testing at Germany’s Wehrteknik Dienstelle (WTD) testing center in Triel has revealed a number of design problems hampering the Puma IFV. Meanwhile, the program’s total estimated cost has risen to EUR 4.3 billion, which is a 39%/ EUR 1.2 billion jump beyond initial program figures.

Changes to the chassis have reportedly been required, with the number of wheel pairs raised from 5 to 6, and engine improvements have been necessary. Weight is reportedly an issue. Electronics are cited as inadequate to achieve the desired performance standards, and even weapon accuracy is questioned.

Meanwhile, German troops must continue using the Marder, which has limitations when fighting at night, and in counter-insurgency missions like Afghanistan where precise target identification is required. Sources: Volksfreund, “Ein Puma mit vielen Problemen” and “Bundeswehr-Panzer Puma wird 1,2 Milliarden Euro teurer”.

June 25/13: Upgrades.Germany will spend another EUR 500 million to develop the Puma after it finishes current trials, with most of these funds spent after 2017. Enhancements will reportedly include electronics upgrades, a remotely-operated machine gun station up top, and provision for anti-tank missiles.

The weapons upgrade will bring Puma to par with new unmanned IFV turrets, and with tracked IFV competitors like American Bradley and Russian BMP. Even the Marder IFVs Puma will replace can carry MBDA’s Milan anti-tank missiles. Sources: RP Online, “Schützenpanzer Puma soll aufgerüstet werden”.

Germany has always been known for producing excellent armored vehicles. A combination of features that arguably make it the world’s best tank, and fire sale prices stemming from Germany’s rapid disarmament, have made the Leopard 2 the standard main battle tank in Europe and beyond. The same level of innovation and execution was shown in the late 1960s, when Germany’s Marder became the west’s first Infantry Fighting Vehicle (IFV). Designs like the American M2/M3 Bradley, Sweden’s CV90 family and new SEP, Singapore’s Bionix-II, and Korea’s new XK-21 have stepped far beyond that legacy, however, and even the Russian region has continued to update their BMP designs. Meanwhile, the nature of military operations has changed to emphasize modularity, out of country missions, advanced electronic communications, and strong protection against threats like land mines.

The Marders need to be replaced, and this became a priority even within Germany’s limited defense budget. In response, German armored vehicle leaders Rheinmetall & KMW formed a 50/50 joint venture to design and produce a solution that would address these issues, and return Germany to a leadership position in the tracked IFV field. Enter the new Puma IFV – which has just received a EUR 3 billion production order from Germany.

Land Panther: Germany’s Tracked Puma IFV

Jun 21, 201418:14 UTC by Defense Industry Daily staff

Heat and cold trials done, formal delivery coming next; More changes will be needed after acceptance; Article reformatted; Additional Readings sections updated.

June 12/14: Heat Trials.Rheinmetall announces that its Puma has successfully completed firing and mobility trials in the UAE, in temperatures that ranged between 35-50C in the shade. The MK30-2/ABM automatic 30mm cannon and the MG4 7.62 machine gun both performed well in stationary and moving firing trials, the air conditioning system held up well and efficiently, and mobility trials went well in sand dunes, steep loose-surface tracks, and a rocky desert streambed.

With the completion of cold and hot-weather trials, the IFV is about ready for acceptance. Sources: Rheinmetall, “Puma stands up to heat and sand”.

Sept 17/13: Testing.German media report that testing at Germany’s Wehrteknik Dienstelle (WTD) testing center in Triel has revealed a number of design problems hampering the Puma IFV. Meanwhile, the program’s total estimated cost has risen to EUR 4.3 billion, which is a 39%/ EUR 1.2 billion jump beyond initial program figures.

Changes to the chassis have reportedly been required, with the number of wheel pairs raised from 5 to 6, and engine improvements have been necessary. Weight is reportedly an issue. Electronics are cited as inadequate to achieve the desired performance standards, and even weapon accuracy is questioned.

Meanwhile, German troops must continue using the Marder, which has limitations when fighting at night, and in counter-insurgency missions like Afghanistan where precise target identification is required. Sources: Volksfreund, “Ein Puma mit vielen Problemen” and “Bundeswehr-Panzer Puma wird 1,2 Milliarden Euro teurer”.

June 25/13: Upgrades.Germany will spend another EUR 500 million to develop the Puma after it finishes current trials, with most of these funds spent after 2017. Enhancements will reportedly include electronics upgrades, a remotely-operated machine gun station up top, and provision for anti-tank missiles.

The weapons upgrade will bring Puma to par with new unmanned IFV turrets, and with tracked IFV competitors like American Bradley and Russian BMP. Even the Marder IFVs Puma will replace can carry MBDA’s Milan anti-tank missiles. Sources: RP Online, “Schützenpanzer Puma soll aufgerüstet werden”.

Germany has always been known for producing excellent armored vehicles. A combination of features that arguably make it the world’s best tank, and fire sale prices stemming from Germany’s rapid disarmament, have made the Leopard 2 the standard main battle tank in Europe and beyond. The same level of innovation and execution was shown in the late 1960s, when Germany’s Marder became the west’s first Infantry Fighting Vehicle (IFV). Designs like the American M2/M3 Bradley, Sweden’s CV90 family and new SEP, Singapore’s Bionix-II, and Korea’s new XK-21 have stepped far beyond that legacy, however, and even the Russian region has continued to update their BMP designs. Meanwhile, the nature of military operations has changed to emphasize modularity, out of country missions, advanced electronic communications, and strong protection against threats like land mines.

The Marders need to be replaced, and this became a priority even within Germany’s limited defense budget. In response, German armored vehicle leaders Rheinmetall & KMW formed a 50/50 joint venture to design and produce a solution that would address these issues, and return Germany to a leadership position in the tracked IFV field. Enter the new Puma IFV – which has just received a EUR 3 billion production order from Germany.

Land Panther: Germany’s Tracked Puma IFV

Indus Falcon

SENIOR MEMBER

- Joined

- Mar 4, 2011

- Messages

- 6,910

- Reaction score

- 107

- Country

- Location

Badgersto get Sagem’s MATIS thermal imagers

Written by defenceWeb, Monday, 23 June 2014

Denel Land Systems has awarded French company Sagem a contract to supply its MATIS thermal imagers on the Badger infantry fighting vehicle (IFV) for the South African Army.

The company will supply three types of infrared imagers to equip different versions of the Badger. The imagers will be produced at the Sagem plant in Poitiers, France, but as part of the industrial participation programme in South Africa, Sagem has partnered with South African company Afrimeasure to do the final integration, along with testing and through-life maintenance.

Sagem said the MATIS range can be used to carry out observation, reconnaissance, identification and engagement missions to a range of several kilometres. The Sagem MATIS imager is easy to integrate in turret-mounted weapon systems and has high performance proven during field testing, according to Sagem.

Sagem has produced more than 6 000 MATIS thermal imagers for major weapon systems in France and international markets. The MATIS SP is a compact, lightweight system suitable for integration into compact sights and small to medium calibre weapons stations for land and naval applications while the MATIS STD is a multipurpose cooled thermal camera for vehicle sights and observation systems. The MATIS LR is a high-end cooled thermal imager with dual field-of-view optics. It is designed to survive severe firing shocks and have long identification ranges.

The South African Army will receive the first of 238 Badger infantry combat vehicles in 2016. The new vehicles will replace the 30-year-old Ratel in all its variants over a ten year period. Serial production will start within the coming 24 months, according to Denel. At the moment the vehicle is undergoing operational testing and evaluation.

The vehicle’s platform is based on a design from Finnish company Patria, which was modified by Denel Land Systems to meet local user requirements including landmine protection, manoeuvrability and firepower.

The initial 16 vehicles will be manufactured in Finland after which the entire production process will be migrated to South Africa. During this second stage 70% of the vehicle will be produced in South Africa. Some of the other suppliers in the programme include Saab, which is supplies a data network and operator displays as well as a digital video system with cameras. The sub-systems will be locally supported in South Africa.

The Badger has been developed in five variants, namely Command, Section, Mortar, Missile and Fire Support derivatives. The main weapon system, used on the Section and Fire Support Variants, is the 30 mm externally-driven cam-operated cannon.

For the Mortar Variant, a 60 mm breech-loading long-range mortar was developed by DLS, along with 60 mm long-range NATO ammunition while the Ingwe anti-tank missile system, developed by Denel Dynamics, is used on the Missile Variant.Denel Land Systems has awarded French company Sagem a contract to supply its MATIS thermal imagers on the Badger infantry fighting vehicle (IFV) for the South African Army.

The company will supply three types of infrared imagers to equip different versions of the Badger. The imagers will be produced at the Sagem plant in Poitiers, France, but as part of the industrial participation programme in South Africa, Sagem has partnered with South African company Afrimeasure to do the final integration, along with testing and through-life maintenance.

Sagem said the MATIS range can be used to carry out observation, reconnaissance, identification and engagement missions to a range of several kilometres. The Sagem MATIS imager is easy to integrate in turret-mounted weapon systems and has high performance proven during field testing, according to Sagem.

Sagem has produced more than 6 000 MATIS thermal imagers for major weapon systems in France and international markets. The MATIS SP is a compact, lightweight system suitable for integration into compact sights and small to medium calibre weapons stations for land and naval applications while the MATIS STD is a multipurpose cooled thermal camera for vehicle sights and observation systems. The MATIS LR is a high-end cooled thermal imager with dual field-of-view optics. It is designed to survive severe firing shocks and have long identification ranges.

The South African Army will receive the first of 238 Badger infantry combat vehicles in 2016. The new vehicles will replace the 30-year-old Ratel in all its variants over a ten year period. Serial production will start within the coming 24 months, according to Denel. At the moment the vehicle is undergoing operational testing and evaluation.

The vehicle’s platform is based on a design from Finnish company Patria, which was modified by Denel Land Systems to meet local user requirements including landmine protection, manoeuvrability and firepower.

The initial 16 vehicles will be manufactured in Finland after which the entire production process will be migrated to South Africa. During this second stage 70% of the vehicle will be produced in South Africa. Some of the other suppliers in the programme include Saab, which is supplies a data network and operator displays as well as a digital video system with cameras. The sub-systems will be locally supported in South Africa.

The Badger has been developed in five variants, namely Command, Section, Mortar, Missile and Fire Support derivatives. The main weapon system, used on the Section and Fire Support Variants, is the 30 mm externally-driven cam-operated cannon.

For the Mortar Variant, a 60 mm breech-loading long-range mortar was developed by DLS, along with 60 mm long-range NATO ammunition while the Ingwe anti-tank missile system, developed by Denel Dynamics, is used on the Missile Variant.

Badgers to get Sagem’s MATIS thermal imagers | defenceWeb

Written by defenceWeb, Monday, 23 June 2014

Denel Land Systems has awarded French company Sagem a contract to supply its MATIS thermal imagers on the Badger infantry fighting vehicle (IFV) for the South African Army.

The company will supply three types of infrared imagers to equip different versions of the Badger. The imagers will be produced at the Sagem plant in Poitiers, France, but as part of the industrial participation programme in South Africa, Sagem has partnered with South African company Afrimeasure to do the final integration, along with testing and through-life maintenance.

Sagem said the MATIS range can be used to carry out observation, reconnaissance, identification and engagement missions to a range of several kilometres. The Sagem MATIS imager is easy to integrate in turret-mounted weapon systems and has high performance proven during field testing, according to Sagem.

Sagem has produced more than 6 000 MATIS thermal imagers for major weapon systems in France and international markets. The MATIS SP is a compact, lightweight system suitable for integration into compact sights and small to medium calibre weapons stations for land and naval applications while the MATIS STD is a multipurpose cooled thermal camera for vehicle sights and observation systems. The MATIS LR is a high-end cooled thermal imager with dual field-of-view optics. It is designed to survive severe firing shocks and have long identification ranges.

The South African Army will receive the first of 238 Badger infantry combat vehicles in 2016. The new vehicles will replace the 30-year-old Ratel in all its variants over a ten year period. Serial production will start within the coming 24 months, according to Denel. At the moment the vehicle is undergoing operational testing and evaluation.

The vehicle’s platform is based on a design from Finnish company Patria, which was modified by Denel Land Systems to meet local user requirements including landmine protection, manoeuvrability and firepower.

The initial 16 vehicles will be manufactured in Finland after which the entire production process will be migrated to South Africa. During this second stage 70% of the vehicle will be produced in South Africa. Some of the other suppliers in the programme include Saab, which is supplies a data network and operator displays as well as a digital video system with cameras. The sub-systems will be locally supported in South Africa.

The Badger has been developed in five variants, namely Command, Section, Mortar, Missile and Fire Support derivatives. The main weapon system, used on the Section and Fire Support Variants, is the 30 mm externally-driven cam-operated cannon.

For the Mortar Variant, a 60 mm breech-loading long-range mortar was developed by DLS, along with 60 mm long-range NATO ammunition while the Ingwe anti-tank missile system, developed by Denel Dynamics, is used on the Missile Variant.Denel Land Systems has awarded French company Sagem a contract to supply its MATIS thermal imagers on the Badger infantry fighting vehicle (IFV) for the South African Army.

The company will supply three types of infrared imagers to equip different versions of the Badger. The imagers will be produced at the Sagem plant in Poitiers, France, but as part of the industrial participation programme in South Africa, Sagem has partnered with South African company Afrimeasure to do the final integration, along with testing and through-life maintenance.

Sagem said the MATIS range can be used to carry out observation, reconnaissance, identification and engagement missions to a range of several kilometres. The Sagem MATIS imager is easy to integrate in turret-mounted weapon systems and has high performance proven during field testing, according to Sagem.

Sagem has produced more than 6 000 MATIS thermal imagers for major weapon systems in France and international markets. The MATIS SP is a compact, lightweight system suitable for integration into compact sights and small to medium calibre weapons stations for land and naval applications while the MATIS STD is a multipurpose cooled thermal camera for vehicle sights and observation systems. The MATIS LR is a high-end cooled thermal imager with dual field-of-view optics. It is designed to survive severe firing shocks and have long identification ranges.

The South African Army will receive the first of 238 Badger infantry combat vehicles in 2016. The new vehicles will replace the 30-year-old Ratel in all its variants over a ten year period. Serial production will start within the coming 24 months, according to Denel. At the moment the vehicle is undergoing operational testing and evaluation.

The vehicle’s platform is based on a design from Finnish company Patria, which was modified by Denel Land Systems to meet local user requirements including landmine protection, manoeuvrability and firepower.

The initial 16 vehicles will be manufactured in Finland after which the entire production process will be migrated to South Africa. During this second stage 70% of the vehicle will be produced in South Africa. Some of the other suppliers in the programme include Saab, which is supplies a data network and operator displays as well as a digital video system with cameras. The sub-systems will be locally supported in South Africa.

The Badger has been developed in five variants, namely Command, Section, Mortar, Missile and Fire Support derivatives. The main weapon system, used on the Section and Fire Support Variants, is the 30 mm externally-driven cam-operated cannon.

For the Mortar Variant, a 60 mm breech-loading long-range mortar was developed by DLS, along with 60 mm long-range NATO ammunition while the Ingwe anti-tank missile system, developed by Denel Dynamics, is used on the Missile Variant.

Badgers to get Sagem’s MATIS thermal imagers | defenceWeb

Indus Falcon

SENIOR MEMBER

- Joined

- Mar 4, 2011

- Messages

- 6,910

- Reaction score

- 107

- Country

- Location

African customer orders 480 Streit security vehicles

Written by defenceWeb, Monday, 23 June 2014

A customer in North Africa has ordered 480 special purpose vehicles for riot control from the Streit Group in the company’s largest ever contract.

The company said the vehicles would be used to fulfil a range of riot control, site illumination and side and front barricade functions, and would be fitted with various urban crowd control equipment.

The 480 vehicles will enter service in early 2015 and will be built at Streit's Ras Al Khaimah factory in the United Arab Emirates. It is one of Streit’s 12 production facilities worldwide.

"The need for riot control and urban response units, both armoured and unarmoured, has grown significantly in the Middle East and Africa in the last few years. Streit is ideally placed to meet this need, thanks to our manufacturing capacity, third-party technology alliances and R&D expertise," said Chief Executive Guerman Goutorov.

"This is a very exciting time for Streit Group. We are set to achieve treble-digit growth, both through new contract awards and through new commercial and armoured personnel carrier lines that we will be demonstrating for the first time at Eurosatory in Paris," he said.

Streit Group specialises in armouring and provides up-armouring and armoured vehicles independently, or in partnership with OEMs. The company has delivered more than 17 000 vehicles, many of which have served in Afghanistan and Iraq. Streit's growing portfolio includes personal protection vehicles, cash-in transit vehicles, heavy-duty cash-in-transit trucks, law-enforcement vehicles and vehicles for military tactical units. Armouring can also be provided for existing civilian platforms such as custom-built luxury sedans and SUVs.

Streit emphasises that everyone who has been involved in an incident while travelling in a Streit Group vehicle has lived to tell the story.

Streit recently launched four new models at the Eurosatory 2014 defence show in Paris, including the Varan 6x6 Armoured Personnel Carrier giving protection against IEDs (Improvised Explosive Devices), landmines, sideblasts and RPG (Rocket Propelled Grenade) attacks. Another of its APCs is the Warrior, offered with an integrated anti-tank guided missile system and protection against threats such as ballistic assaults, mines and grenades.

The Streit Typhoon 6x6 is an MRAP (Mine Resistant Ambush Protected) vehicle, developed and built to withstand attacks, including ballistic arms fire, mines and IEDs. Also on show was the bomb disposal variant of Streit's Shrek MRAP range, which features an extendable mine or IED arm as well as excellent blast and ballistic protection.

Along with these newcomers Streit showcased its Scorpion APC, which has been tested and certified to STANAG 3 blast protection standard and is ready for STANAG 4 testing.

African customer orders 480 Streit security vehicles | defenceWeb

Written by defenceWeb, Monday, 23 June 2014

A customer in North Africa has ordered 480 special purpose vehicles for riot control from the Streit Group in the company’s largest ever contract.

The company said the vehicles would be used to fulfil a range of riot control, site illumination and side and front barricade functions, and would be fitted with various urban crowd control equipment.

The 480 vehicles will enter service in early 2015 and will be built at Streit's Ras Al Khaimah factory in the United Arab Emirates. It is one of Streit’s 12 production facilities worldwide.

"The need for riot control and urban response units, both armoured and unarmoured, has grown significantly in the Middle East and Africa in the last few years. Streit is ideally placed to meet this need, thanks to our manufacturing capacity, third-party technology alliances and R&D expertise," said Chief Executive Guerman Goutorov.

"This is a very exciting time for Streit Group. We are set to achieve treble-digit growth, both through new contract awards and through new commercial and armoured personnel carrier lines that we will be demonstrating for the first time at Eurosatory in Paris," he said.

Streit Group specialises in armouring and provides up-armouring and armoured vehicles independently, or in partnership with OEMs. The company has delivered more than 17 000 vehicles, many of which have served in Afghanistan and Iraq. Streit's growing portfolio includes personal protection vehicles, cash-in transit vehicles, heavy-duty cash-in-transit trucks, law-enforcement vehicles and vehicles for military tactical units. Armouring can also be provided for existing civilian platforms such as custom-built luxury sedans and SUVs.

Streit emphasises that everyone who has been involved in an incident while travelling in a Streit Group vehicle has lived to tell the story.

Streit recently launched four new models at the Eurosatory 2014 defence show in Paris, including the Varan 6x6 Armoured Personnel Carrier giving protection against IEDs (Improvised Explosive Devices), landmines, sideblasts and RPG (Rocket Propelled Grenade) attacks. Another of its APCs is the Warrior, offered with an integrated anti-tank guided missile system and protection against threats such as ballistic assaults, mines and grenades.

The Streit Typhoon 6x6 is an MRAP (Mine Resistant Ambush Protected) vehicle, developed and built to withstand attacks, including ballistic arms fire, mines and IEDs. Also on show was the bomb disposal variant of Streit's Shrek MRAP range, which features an extendable mine or IED arm as well as excellent blast and ballistic protection.

Along with these newcomers Streit showcased its Scorpion APC, which has been tested and certified to STANAG 3 blast protection standard and is ready for STANAG 4 testing.

African customer orders 480 Streit security vehicles | defenceWeb

Water Car Engineer

ELITE MEMBER

- Joined

- Sep 25, 2010

- Messages

- 13,313

- Reaction score

- 8

- Country

- Location

TATA's Wheeled FICV

Tracked coming soon

Penguin

ELITE MEMBER

- Joined

- Jan 11, 2009

- Messages

- 13,047

- Reaction score

- 56

Water Car Engineer

ELITE MEMBER

- Joined

- Sep 25, 2010

- Messages

- 13,313

- Reaction score

- 8

- Country

- Location

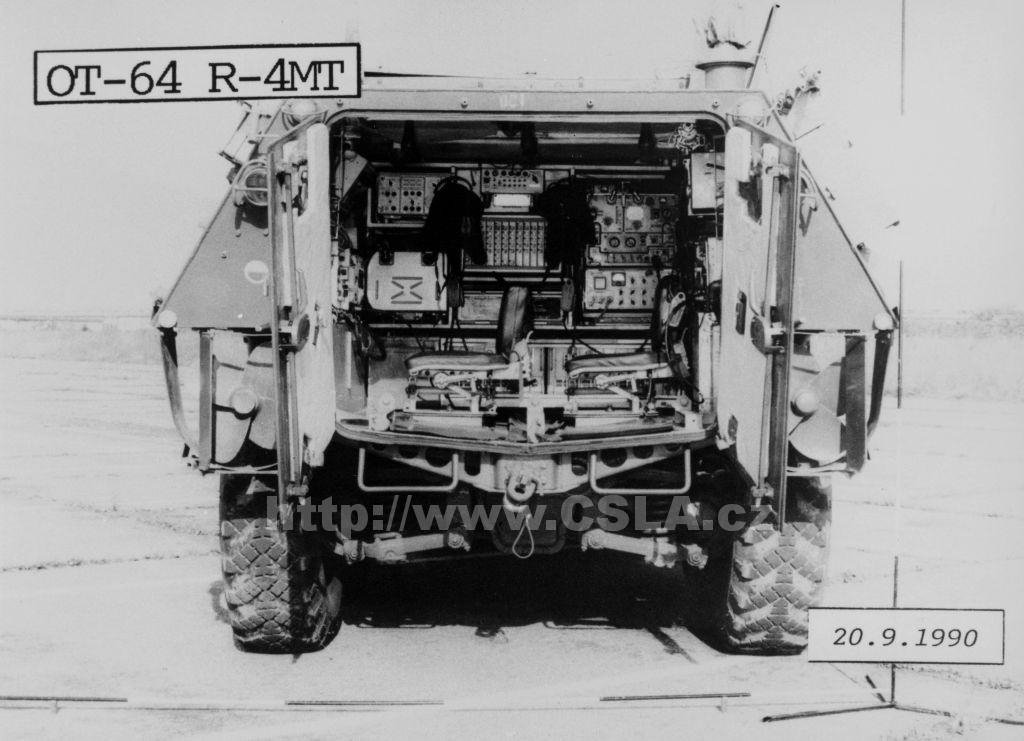

Inspired byTatra OT-64 Skot?

http://www.csla.cz/technika/transportery/ot64r2.htm

Possibly, India did operate these a while ago. DRDO was the technical partner too.

Similar threads

- Replies

- 0

- Views

- 1K

- Replies

- 37

- Views

- 4K

- Replies

- 1

- Views

- 124

- Replies

- 0

- Views

- 2K