How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pakistan Aircraft Industries.

- Thread starter ghazi52

- Start date

ghazi52

PDF THINK TANK: ANALYST

- Joined

- Mar 21, 2007

- Messages

- 101,806

- Reaction score

- 106

- Country

- Location

Pakistan keeps aging Mirages flying

A Mirage aircraft of the Pakistan Air Force (PAF) prepares for a first test run at the Pakistan Aeronautical Complex after an overhaul at the Mirage Rebuild Factory (MRF) in Kamra. (AFP)

In this file photo, technicians work on a Mirage aircraft during a full overhaul by the Pakistan Air Force (PAF) at the Mirage Rebuild Factory (MRF) in Kamra. (AFP)

In this file photo, technicians work on a Mirage aircraft during a full overhaul by the Pakistan Air Force (PAF) at the Mirage Rebuild Factory (MRF) in Kamra,

AFP

KAMRA, Pakistan: The sprawling complex at Kamra, west of Islamabad, reverberates at the thundering take-off of a Mirage Rose-1, the latest aging fighter jet to have been gutted and reassembled by the Pakistani Air Force.

Fifty years after Pakistan bought its first Mirages, many planes in the venerable fleet are still being patched up, overhauled and upgraded for use in combat, years after conventional wisdom dictates they should be grounded.

That includes one of the first two planes originally purchased from France’s Dassault in 1967, which was in a hangar at Kamra after its record fifth overhaul when AFP visited recently.

The techniques they have developed are reminiscent of — but far more high-tech and lethal than — the improvised methods used to keep classic American cars running on the streets of Havana.

“We have achieved such a capability that our experts can integrate any latest system with the aging Mirages,” says Air Commodore Salman M. Farooqi, deputy managing director of the Mirage Rebuild Factory (MRF) at the Kamra complex.

Pakistan bought its first Mirages to diversify its fleet, which in the late 1960s largely consisted of US-built planes: F-104 Starfighters, T-37 Tweety Birds and F-86 Sabres.

The Mirage became a popular choice, with the Air Force buying 17 different variants in later years, eventually owning the second-highest number of the fighter jets after France.

They performed bombing missions during Pakistan’s war with India in 1971 — one of the shortest conflicts in history, lasting just 13 days and leading to the creation of Bangladesh.

But Mirages flew on, also carrying out reconnaissance missions in India, and intercepting and shooting down Soviet and Afghan planes that violated Pakistani airspace during the Soviet war.

Usually, the jet has two or three life cycles, each spanning around 12 years. But overhauling them abroad was expensive for Pakistan, a developing country whose budget is already disproportionately tilted toward its military and which has historically received billions in military assistance from countries such as the US.

So, with the help of experts from Dassault, the air force decided if you want something done for the right price, you’ve got to do it yourself.

The Mirage Rebuild Factory was established at the Pakistan Aeronautical Complex (PAC) in 1978, and in the years since has saved “billions” of dollars for Pakistan, according to Group Captain Muhammad Farooq, in charge of one of the maintenance hangars — though he said the exact figure was difficult to pin down.

The planes take some seven weeks to be overhauled and repainted, he said, adding that usually the MRF has the capacity for more than a dozen planes a year. Its calendar for the next decade or so is already booked up.

At least eight different Mirage variants, including the Mirage 5-EF, Mirage III-DP and Mirage-III Rose-I, were in one of the maintenance hangers when AFP visited.

Engineers and technicians were dismantling cockpit instrument panels and landing gear while undertaking a “non-destructive inspection,” essentially an X-ray to detect faults in the wings and airframe.

Dozens of engines awaiting overhaul were piled in one hangar. Even planes that had suffered accidents such as fires breaking out have been patched back together at the facility.

Pakistan has also been buying up discarded Mirages from other countries to bring through the facility, said retired Air Marshal Shahid Lateef.

The most important technological improvement, developed with the help of South Africa, is the ability to integrate air-to-air refueling, Farooqi said.

The “identification of friend and foe” (IFF) system, which detects when a Mirage has been locked on to by the system of another plane, was also a key development, he said.

But even with the improvements and cost-saving measures, the aging planes are becoming more difficult to maintain.

“They have outlived their lives... after their overhauls (they) have become highly unreliable, we even met with lots of accidents,” Lateef said.

The best option to replace them would be the Rafale, as neighbor and arch-rival India — which has also flown and maintained Mirages for decades — is doing, signing a deal with Dassault in 2016.

The price tag is too much for Pakistan, however, retired Air Commodore Tariq Yazdani said.

Instead Pakistan plans to replace them with the JF-17 Thunder aircraft that it co-developed and co-produced with China, the original manufacturer.

Even as it becomes more urgent to phase them out, Mirages’ status as the grand dames of Pakistani military aviation cannot be dismissed, Yazdani, who has logged 1,500 hours flying them, told AFP.

It is a “very agile aircraft capable of penetrating deep into the enemy’s territory without being detected by radar, which makes its sole mission -– to drop bombs on the enemy’s position -– quite easy,” he said.

“It is an old aircraft,” said aviation writer Alan Warnes, author of two books on the Pakistani air force. “But Pakistani pilots have been flying this plane with the utmost accuracy and expertise.”

A Mirage aircraft of the Pakistan Air Force (PAF) prepares for a first test run at the Pakistan Aeronautical Complex after an overhaul at the Mirage Rebuild Factory (MRF) in Kamra. (AFP)

In this file photo, technicians work on a Mirage aircraft during a full overhaul by the Pakistan Air Force (PAF) at the Mirage Rebuild Factory (MRF) in Kamra. (AFP)

In this file photo, technicians work on a Mirage aircraft during a full overhaul by the Pakistan Air Force (PAF) at the Mirage Rebuild Factory (MRF) in Kamra,

AFP

KAMRA, Pakistan: The sprawling complex at Kamra, west of Islamabad, reverberates at the thundering take-off of a Mirage Rose-1, the latest aging fighter jet to have been gutted and reassembled by the Pakistani Air Force.

Fifty years after Pakistan bought its first Mirages, many planes in the venerable fleet are still being patched up, overhauled and upgraded for use in combat, years after conventional wisdom dictates they should be grounded.

That includes one of the first two planes originally purchased from France’s Dassault in 1967, which was in a hangar at Kamra after its record fifth overhaul when AFP visited recently.

The techniques they have developed are reminiscent of — but far more high-tech and lethal than — the improvised methods used to keep classic American cars running on the streets of Havana.

“We have achieved such a capability that our experts can integrate any latest system with the aging Mirages,” says Air Commodore Salman M. Farooqi, deputy managing director of the Mirage Rebuild Factory (MRF) at the Kamra complex.

Pakistan bought its first Mirages to diversify its fleet, which in the late 1960s largely consisted of US-built planes: F-104 Starfighters, T-37 Tweety Birds and F-86 Sabres.

The Mirage became a popular choice, with the Air Force buying 17 different variants in later years, eventually owning the second-highest number of the fighter jets after France.

They performed bombing missions during Pakistan’s war with India in 1971 — one of the shortest conflicts in history, lasting just 13 days and leading to the creation of Bangladesh.

But Mirages flew on, also carrying out reconnaissance missions in India, and intercepting and shooting down Soviet and Afghan planes that violated Pakistani airspace during the Soviet war.

Usually, the jet has two or three life cycles, each spanning around 12 years. But overhauling them abroad was expensive for Pakistan, a developing country whose budget is already disproportionately tilted toward its military and which has historically received billions in military assistance from countries such as the US.

So, with the help of experts from Dassault, the air force decided if you want something done for the right price, you’ve got to do it yourself.

The Mirage Rebuild Factory was established at the Pakistan Aeronautical Complex (PAC) in 1978, and in the years since has saved “billions” of dollars for Pakistan, according to Group Captain Muhammad Farooq, in charge of one of the maintenance hangars — though he said the exact figure was difficult to pin down.

The planes take some seven weeks to be overhauled and repainted, he said, adding that usually the MRF has the capacity for more than a dozen planes a year. Its calendar for the next decade or so is already booked up.

At least eight different Mirage variants, including the Mirage 5-EF, Mirage III-DP and Mirage-III Rose-I, were in one of the maintenance hangers when AFP visited.

Engineers and technicians were dismantling cockpit instrument panels and landing gear while undertaking a “non-destructive inspection,” essentially an X-ray to detect faults in the wings and airframe.

Dozens of engines awaiting overhaul were piled in one hangar. Even planes that had suffered accidents such as fires breaking out have been patched back together at the facility.

Pakistan has also been buying up discarded Mirages from other countries to bring through the facility, said retired Air Marshal Shahid Lateef.

The most important technological improvement, developed with the help of South Africa, is the ability to integrate air-to-air refueling, Farooqi said.

The “identification of friend and foe” (IFF) system, which detects when a Mirage has been locked on to by the system of another plane, was also a key development, he said.

But even with the improvements and cost-saving measures, the aging planes are becoming more difficult to maintain.

“They have outlived their lives... after their overhauls (they) have become highly unreliable, we even met with lots of accidents,” Lateef said.

The best option to replace them would be the Rafale, as neighbor and arch-rival India — which has also flown and maintained Mirages for decades — is doing, signing a deal with Dassault in 2016.

The price tag is too much for Pakistan, however, retired Air Commodore Tariq Yazdani said.

Instead Pakistan plans to replace them with the JF-17 Thunder aircraft that it co-developed and co-produced with China, the original manufacturer.

Even as it becomes more urgent to phase them out, Mirages’ status as the grand dames of Pakistani military aviation cannot be dismissed, Yazdani, who has logged 1,500 hours flying them, told AFP.

It is a “very agile aircraft capable of penetrating deep into the enemy’s territory without being detected by radar, which makes its sole mission -– to drop bombs on the enemy’s position -– quite easy,” he said.

“It is an old aircraft,” said aviation writer Alan Warnes, author of two books on the Pakistani air force. “But Pakistani pilots have been flying this plane with the utmost accuracy and expertise.”

ghazi52

PDF THINK TANK: ANALYST

- Joined

- Mar 21, 2007

- Messages

- 101,806

- Reaction score

- 106

- Country

- Location

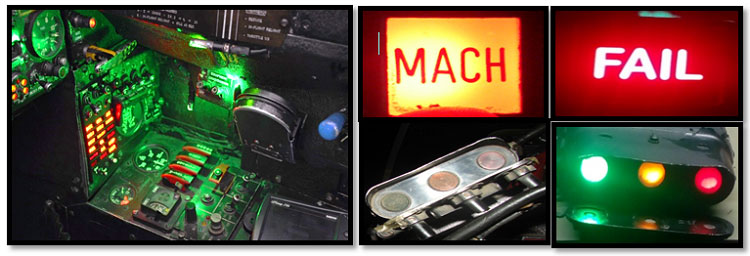

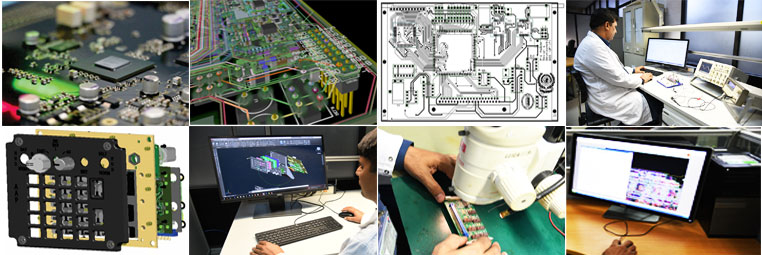

AVIONICS PRODUCTION FACTORY

Commercial services

PCB Stuffing Facility

Avionics Production Factory (APF) has state of the art for stuffing facility of both Surface Mount Technology (SMT) and Through Hole Technology (THT). The facility includes optical inspection, X-ray inspection, PCB treatment (PCB Washing, lonic contamination testing, Conformal coating etc.), Functional Testing, In-circuit Testing (ICT) and Environmental Stress Screening (Component to System level). APF provides comprehensive service in the mentioned categories and has gained rich experience with customer satisfaction. We can handle high volume and prototype quantity. We adhere to IPC standards and are AS 9100-D certified. The salient features are as under:

- Stuffing for through hole and surface mounted devices (SMDs) in accordance with quality standards IPC-A-600H and IPC-A-610E

- Prototyping and high volume production

- Single type or hybrid stuffing process

- Repair & Rework

- Programmable, hot-air based and IR based rework system

- Mil Std 810-D compliance

- Conformal Coating for humidity and environmental control

- Optical and X-ray inspection

- ESS (Vibration, Thermal Vibration, Climatic, Thermal Altitude, Thermal Shock) Polymer based potting of high voltage power supplies by vacuum suction method

- Assembly of cable harnesses and winding of transformers

- ESS profiling and testing

- Single axis random vibration systems

- Fabrication of interconnection aircraft looms

- Production from base level i.e. from completely knocked down and semi knocked down kits

Conformal Coating

Conformal coating is an extra cost operation. Boards not in standard panel size will require additional tooling. Humiseal Coatings and Silicon types of conformal coating can be offered. Conformal coting is done as per coating map provided by the customer to meet the product requirement. Coating map is to include thickness of coating and no cat areas and components.

Optical and X-Ray Inspection

APF can perform the optical and 3D X-ray inspection of the product assembly upon the customer request and its reports can be sent with the product for Quality assurance to our valuable customer. These inspections reports are very useful if the product assembly contains BGAs and some fine pitch QFPs. X-ray inspection can be performed for electronic PCBs up to size of 400x400mm (16 inch x 16 inch). It is useful in determining BGA and micro BGA faults like short circuited balls, over and under sized balls, solder voids and quality of balls. It can also identify broken connections inside the ICs.

PCB Treatment

Availability of corrosive and conductive particles of the flux or solder past may lead to jeopardizing the product reliability in spite of excellent workmanship. This may not be applicable to the non-clean flux / solder paste but if the customer specify or supply consumable material with the RMA fluxes or VOC water based fluxes then PCB washing becomes an essential process in the product assembly. APF can offer PCB washing upon the customer request or from the selection of material by the customer specific applications. This can eliminate all the corrosive and conductive particle of flux from the product assembly. Lonic contamination can also be verified and reports can also be provided to the customer on request.

Last edited:

ghazi52

PDF THINK TANK: ANALYST

- Joined

- Mar 21, 2007

- Messages

- 101,806

- Reaction score

- 106

- Country

- Location

Environmental Stress Screening

ESS is widely used in military and aerospace applications to detect product defects and production flaws. APF has complete range of ESS facilities including Thermal climatic chamber, Vertical vibration shaker, Horizontal vibration slip table and Altitude, pressure and temperature chambers.

Testing Solution Development

APF has capability of providing complete testing solutions for electronic LRU’s / PCBs using industry standard Teradyne Functional and in-circuit testers. NHR tester is used for Mil-Std-704 qualification of various types of power supplies. Additionally, APF also manufactures wide variety of test fixtures for digital systems, power supplies and RF / microwave devices under test (DUT).

RF / Microwave Cleanroom and Anechoic Testing Facility

APF has ISO Class 8 Microwave clean room facility for RF / microwave modules and PCBs. Facility can undertake high volume production of RF / microwave modules, RF cable assembly, Antenna lamination and repair. Furthermore, automated testing using RF test station and Antennae testing for L&X band using anechoic chamber can be carried out.

EMI / EMC Testing Facility

APF, PAC EMC/ EMI Testing Lab is equipped with state of the art R&S equipment (wide frequency range from 2Hz to 44 GHz) for RF system debugging and interface analysis. The lab possesses software controlled automated testing capability to perform on-platform testing of electronic equipment for analyzing its mutual compatibility with other electronic equipment. These tests comply with MIL-STD 461 and MIL-STD 464 (CE-101, CE-102, RE-101, RE-102) for conductive and radiated emission and susceptibility. The mobile nature of facility allows carrying out on-site EMC testing also.

PME Calibration

APF has comprehensive PME Calibration facility which is accredited with ISO 17025:2017. It has 26 Reference Standards and 136 Working Standards. The calibration capability includes Electrical Systems, RF / VXI based Systems and Physical Test Equipment. Salient PME being calibrated include AC / DC Power Supplies, Oscilloscopes, LCR Meters, Frequency Counter, Signal Generators, Spectrum Analyzer, Air Speed Indicators, Pressure Gauges, Temperature Gauges etc.

NVIS Compatible Cockpit Panels

APF has also gained expertise in manufacturing of Military Standard 3009 Type ‘I’ Night Vision capable cockpit panels. Some of the important areas undertaken by APF in night vision capability include manufacturing of PCBs for NVIS Class ‘A’ and ‘B’ compatible panels, NVIS backlighting for aircraft instruments and NVIS filters for aircraft indicators. The technical prowess of APF resulted in Form fit functional NVIS capable multiple aircraft cockpit.

ESS is widely used in military and aerospace applications to detect product defects and production flaws. APF has complete range of ESS facilities including Thermal climatic chamber, Vertical vibration shaker, Horizontal vibration slip table and Altitude, pressure and temperature chambers.

Testing Solution Development

APF has capability of providing complete testing solutions for electronic LRU’s / PCBs using industry standard Teradyne Functional and in-circuit testers. NHR tester is used for Mil-Std-704 qualification of various types of power supplies. Additionally, APF also manufactures wide variety of test fixtures for digital systems, power supplies and RF / microwave devices under test (DUT).

RF / Microwave Cleanroom and Anechoic Testing Facility

APF has ISO Class 8 Microwave clean room facility for RF / microwave modules and PCBs. Facility can undertake high volume production of RF / microwave modules, RF cable assembly, Antenna lamination and repair. Furthermore, automated testing using RF test station and Antennae testing for L&X band using anechoic chamber can be carried out.

EMI / EMC Testing Facility

APF, PAC EMC/ EMI Testing Lab is equipped with state of the art R&S equipment (wide frequency range from 2Hz to 44 GHz) for RF system debugging and interface analysis. The lab possesses software controlled automated testing capability to perform on-platform testing of electronic equipment for analyzing its mutual compatibility with other electronic equipment. These tests comply with MIL-STD 461 and MIL-STD 464 (CE-101, CE-102, RE-101, RE-102) for conductive and radiated emission and susceptibility. The mobile nature of facility allows carrying out on-site EMC testing also.

PME Calibration

APF has comprehensive PME Calibration facility which is accredited with ISO 17025:2017. It has 26 Reference Standards and 136 Working Standards. The calibration capability includes Electrical Systems, RF / VXI based Systems and Physical Test Equipment. Salient PME being calibrated include AC / DC Power Supplies, Oscilloscopes, LCR Meters, Frequency Counter, Signal Generators, Spectrum Analyzer, Air Speed Indicators, Pressure Gauges, Temperature Gauges etc.

- Humidity

- Temperature

- Dimensional Equipment (Vernier Caliper, dial Tester, Gauge blocks, Weighing Scales, 3-axis measurement)

- Multifunction Electrical Calibration

- Analogue /Digital Multi-meters

- Analogue / Digital DC Power Supplies

- DC Electronics Loads

- Digital Oscilloscopes

- Soldering Stations 7 Temperature

- Bath / Chambers

- LCR Meters

- Meggars

- VXI Modules

- RF Cables & Power Splitters

- Spectrum Analyzers

- Frequency Counters & Signal Generators

- Power Meters & Sensors

- Pressure Gauges (Air / Water / Hydraulic)

- Temperature Gauges (with thermocouples)

- Torque Wrenches

NVIS Compatible Cockpit Panels

APF has also gained expertise in manufacturing of Military Standard 3009 Type ‘I’ Night Vision capable cockpit panels. Some of the important areas undertaken by APF in night vision capability include manufacturing of PCBs for NVIS Class ‘A’ and ‘B’ compatible panels, NVIS backlighting for aircraft instruments and NVIS filters for aircraft indicators. The technical prowess of APF resulted in Form fit functional NVIS capable multiple aircraft cockpit.

ghazi52

PDF THINK TANK: ANALYST

- Joined

- Mar 21, 2007

- Messages

- 101,806

- Reaction score

- 106

- Country

- Location

Mirage Rebuild Factory, PAC Kamra

Capabilities of Engine Group MRF

Special Processes

The special processes available at Engine Group include: -

Assembly / Disassembly and Testing Facilities for Engine and Accessories

The capabilities related to Assembly / Disassembly and Testing Facilities for Engine and Accessories include: -

Calibration Processes

The Calibration Processes available at Engine Group include: -

Documentation Processes

The Documentation Processes of Engine Group consists of: -

- Delta/GV inspection of Mirage III/V aircraft

- Complete overhauling of Mirage aircraft Martin Baker ejection seat PRM-4 and OM-6

- Hot harmonization of Mirage aircraft and its variants

- 4th Line Maintenance facility of Mirage III/V aircraft components

- 4th Line maintenance of JF-17 emergency oxygen system components

- Trial repair of non Mirage components

- Mirage Pressure Refueling (MPR) air to air refueling modification of Mirage aircraft

- A non Destructive Inspection (NDI) technique includes Penetrant Testing (PT), Magnetic Particle Inspection (MPI), Ultrasonic Technique (UT), Radiography Technique (RT) and Videoscopic inspection

- Capability of NDI of Mirage, SAAB, JF-17 and UAV aircrafts

- Structure repair and wing overhaul of Mirage aircraft

- Structure repair of SAAB aircraft

- PCAA ANO-001 approved CNC pipe bending facility for Mirage, SAAB and DA-20 aircrafts

- Aircraft painting according to American Federal 595 and French Air 8104 standards of Mirage, F-16, JF-17, DA-20, Cessna, Mushshak, K-8 and other light body aircrafts

Capabilities of Engine Group MRF

Special Processes

The special processes available at Engine Group include: -

- Heat and Surface Treatment

- Machining, Welding and Metal Processes

- Plasma and HVOF Processes

- Shot Peening

- Painting

- Penetrant Testing

- Magnetic Particle Testing

- Eddy Current Testing

- Ultra-Sonic Testing

- Radiography

- Radioscopy

Assembly / Disassembly and Testing Facilities for Engine and Accessories

The capabilities related to Assembly / Disassembly and Testing Facilities for Engine and Accessories include: -

- Engines Assembly and Disassembly Docks

- Assembly and Disassembly benches for engine accessories

- Test Bed for ATAR, F100 and Turboprop Engines

- Oil and Fuel Accessories Test Benches

- Special Bearing and Kinematics checking facilities

- Static and Dynamic Balancing Machines

- Inspection services for all engines at MRF

Calibration Processes

The Calibration Processes available at Engine Group include: -

- Hygrometers

- Vernier Calipers

- Dial Test Indicator

- Gauge Blocks

- Weighing Scales / Masses

- 3-axis Measurements

- Analogue / Digital Multimeters

- Analogue / Digital AC / DC Power Supplies

- AC / DC Panels Meters

- Frequency Counters & Signal Generators

- Meggers / Insulation Meters

- Temperature Baths / Furnaces

- Temperature Gauges (with thermocouples)

- Torque Wrenches / Meters

- Pressure Gauges (Air/water/Hydraulic)

Documentation Processes

The Documentation Processes of Engine Group consists of: -

- Engine production software for tracking of Engines, Accessories, Parts and sub parts

- Repair, Inspection, Assembly and Testing controlled through software

- Technical Order Distribution Office

- Method Design Offices which establishes and controls Repair and Assembly schemes of all parts and accessories

ghazi52

PDF THINK TANK: ANALYST

- Joined

- Mar 21, 2007

- Messages

- 101,806

- Reaction score

- 106

- Country

- Location

Avionics Production Factory, PAC Kamra

Ground Radars MRO

APF has comprehensive MRO facility for ground radars which includes overhauling and refurbishment of low and high level radar systems through antenna structural repairs, testing and refurbishment along with complete electronics testing, optimization and calibration. APFs continuous efforts in maintaining these systems ensures operational availability of PAF’s Air Defence.

Avionics Production

APF is a qualified Avionics system manufacturer. State of the art automated facilities are utilized for production, testing and environmental stress screening of Avionics systems to meet aircraft production needs. Today APF has capability to provide complete solution from initial concept to product qualification. A good number of fighter aircraft Avionics systems have been indigenously developed by APF and are operationally flying. Its state of the art generic production and testing line has produced.

Life Cycle Support

APF has an elaborated testing and repair facility for life cycle support of PAF avionics systems. Moreover, cost effective maintenance solutions are provided through indigenous testers development. APF forms the backbone of LCS Systems. Challenge of obsolescence is for vintage systems is being mitigated through indigenization efforts.

Avionics Development

Indigenization is APF’s strategic focus and as part of the deletion program, APF developed core capability in hardware, software design & development of systems. APF, now is a proud OEM of multiple Avionics systems that have underwent completely indigenous development, from initial concept to final qualification.

Avionics Integration

APF holds the coveted status of certified Avionics integrator for advanced fighter jet and has independently integrated Avionics of PAF’s choice on fighter aircraft. The indigenous software release developed by APF provides a tremendous boost to operational and strike capabilities of PAF.

Ground Radars MRO

APF has comprehensive MRO facility for ground radars which includes overhauling and refurbishment of low and high level radar systems through antenna structural repairs, testing and refurbishment along with complete electronics testing, optimization and calibration. APFs continuous efforts in maintaining these systems ensures operational availability of PAF’s Air Defence.

Avionics Production

APF is a qualified Avionics system manufacturer. State of the art automated facilities are utilized for production, testing and environmental stress screening of Avionics systems to meet aircraft production needs. Today APF has capability to provide complete solution from initial concept to product qualification. A good number of fighter aircraft Avionics systems have been indigenously developed by APF and are operationally flying. Its state of the art generic production and testing line has produced.

Life Cycle Support

APF has an elaborated testing and repair facility for life cycle support of PAF avionics systems. Moreover, cost effective maintenance solutions are provided through indigenous testers development. APF forms the backbone of LCS Systems. Challenge of obsolescence is for vintage systems is being mitigated through indigenization efforts.

Avionics Development

Indigenization is APF’s strategic focus and as part of the deletion program, APF developed core capability in hardware, software design & development of systems. APF, now is a proud OEM of multiple Avionics systems that have underwent completely indigenous development, from initial concept to final qualification.

Avionics Integration

APF holds the coveted status of certified Avionics integrator for advanced fighter jet and has independently integrated Avionics of PAF’s choice on fighter aircraft. The indigenous software release developed by APF provides a tremendous boost to operational and strike capabilities of PAF.

Last edited:

ghazi52

PDF THINK TANK: ANALYST

- Joined

- Mar 21, 2007

- Messages

- 101,806

- Reaction score

- 106

- Country

- Location

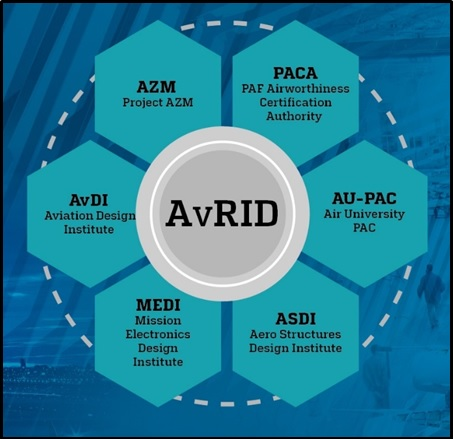

AvRID

Aviation Research, Indigenization & Development

The office of DG AvRID has been established to transform into reality the Air Staff vision as stated above, with the long-term goal of developing our own fifth generation fighter aircraft (FGFA). Development of FGFA would be a major national program that would entail massive amount of work; not all of which may possibly be carried out within PAC, or even within Pakistan. Such large-scale development requires synergetic efforts from a number of industrial (public & private) and academic organizations to fulfill the enormous task. These efforts by themselves will enable development of technologies that will find applications in a number of other systems. The guiding motto will be “cooperation within, competition outside”.

In order to manage an engineering development program of this magnitude, an effective system covering the technical and management aspects needs to be put in place. A sound system engineering approach will have to be followed to ensure the technical health of the program backed by an equally sound project management effort to support it. As the development of FGFA is a major program, it will have to be divided into a number of projects, for which separate project teams will have to be formed. One team would be working on core capabilities development, another on aircraft development, one on avionics development, yet another on facilities development, one on human resource development and so on. There would be specialist teams for development of each system. Depending on the complexity of the systems, these teams would vary in the nature and extent of multi-disciplines. Some teams will be co-located while others would operate across different organizations. Similarly, certain functions will be performed by dedicated project teams while others by matrix teams.

Engineering Management & Support (EMS).

An elaborate plan for development of FGFA and associated technological capabilities will be prepared by DG AvRID. The plan will have to define the different projects within the program and define project teams and their plans in consultation with specialist resource personnel and organizations. The office would be responsible to manage the resources, schedules, risks and stakeholders throughout the program. It would also be responsible for establishing formal system engineering, configuration management and quality assurance processes within the participating teams and organizations. In order to carry out these functions, EMS activities will have to be appropriately organized within an EMS group in DG AvRID Secretariat and manned by qualified personnel: -

(a) Academia Industry Collaboration Office (AICO). For optimum utilization of resources available within academia and industry of the country and abroad.

(b) Systems Engineering Processes Office (SEPO). For training and audit of systems engineering and configuration management processes within participating organizations.

(c) Capability Development Office (CDO). For planning, assisting and tracking capability development encompassing facilities, technology and human resource.

(d) Quality Assurance and Certification Office (QACO). For training and audit of quality assurance and certification standards within participating organizations.

(e) Program Plans Office (PPO). For overall planning, budgeting and resource allocation.

(f) Program Execution Office (PEO). For program execution.

The office of DG AvRID will pursue an active engagement with the public and private sector for expanding the industrial base of the country to meet aviation requirements of Pakistan and to venture into the global aviation market for sustainable technical and economic growth. It will foster international collaboration and linkages to address critical technological gaps. It will also pursue HEC and higher education institutes to ensure that training needs in technologies critical to aviation industry are adequately identified and addressed. It will work with CAE, AU, NUST, IST and other institutes for utilization of their researchers, students, labs and alumni for conducting R&D in appropriate areas. The office will carry out its tasks through the following elements that report to it directly. Additional elements may be added if and when required.

Project AZM.

This project aims to develop a fifth-generation fighter aircraft as per ASR requirements. As mentioned earlier, this is a major undertaking that will require synergetic participation of a large number of organizations and stakeholders. A phased but aggressive approach will be followed to overcome technical challenges as soon as they are identified. A number of challenges like materials, propulsion, sensors, mission systems etc. are already known and risk mitigation plans are being worked out. The strategy is to keep focus of the FGFA team on aircraft development while other elements of AvRID focus on providing the required technologies and systems for project success.

Aviation Design Institute (AvDI).

This institute has been established to develop the core multidisciplinary technologies required for any advanced air vehicle. It is envisaged to bring together experts with varied backgrounds (Aero, Elects, Wpns) and specialties (both Aerospace & Avionics) to work on areas like aerodynamics, antennas, fly-by-wire, payloads, sensor fusion, stealth, structures, etc. The institute undertakes projects that provide solutions in the immediate and short term and in doing so contribute to developing technologies for medium and long-term product development projects like FGF.

Mission Electronics Design Institute (MEDI).

This institute will develop critical technologies like high performance computing boards, advanced avionics interfaces etc. The technologies will be used for design & development of mission computers, flight control computers, etc. Considering the fast pace of development in the field of electronics leading to early obsolescence and the huge amount of data crunching onboard the FGFA, considerable challenges will have to be overcome.

Aero Structures Design Institute (ASDI).

This institute will be responsible for design and analysis of aero structures, including Damage Tolerance Analysis (DTA). It will also interact with the local industry and academia for identifying and developing materials required for aerospace related applications.

Advanced Technologies Centre (ATC).

This Centre will form the PAF element of the Faculty of Aerospace and Aviation Campus AU Kamra and will focus on MS and PhD programs in Aerospace and Avionics disciplines. These programs, in coordination with CAE and other institutes will provide the necessary human resource for programs like FGFA. They will also assist in setting up labs in critical areas and carry out focused research. Short courses in relevant areas will also be arranged.

Flight Test Centre (FTC).

The capability to carry out flight testing of developed systems and platforms will be eventually consolidated into a dedicated flight test Centre. It will assist and coordinate flight testing activities with customers. It would develop the procedures and protocols for flight testing and certification in coordination with development teams and certification authorities, as applicable.

AvRID Capabilities

Aviation City’s evolution transforms PAC Kamra into a teaching industry by bridging itself with co-located Air University Campus. Entire infrastructure of production, upgrade/ overhaul, research & development, qualification and certification would be opened to the students of Air University, thus equipping them with higher academic knowledge and professional skills. These students would be fully fielded in all such disciplines under collaborative supervision of Air University faculty and engineering leadership of the factories.

The multi-discipline research team at Aviation Research, Indigenization & Development (AvRID) Centre will include an effective mix of highly qualified and/or experienced specialists, who would leverage industrial and academic potential available to Kamra. This would put together components of industry and academia to build a high-end research center to enhance indigenization capability. AvRID at Kamra is destined to be the embodiment of this aim.

Aviation Research, Indigenization & Development

The office of DG AvRID has been established to transform into reality the Air Staff vision as stated above, with the long-term goal of developing our own fifth generation fighter aircraft (FGFA). Development of FGFA would be a major national program that would entail massive amount of work; not all of which may possibly be carried out within PAC, or even within Pakistan. Such large-scale development requires synergetic efforts from a number of industrial (public & private) and academic organizations to fulfill the enormous task. These efforts by themselves will enable development of technologies that will find applications in a number of other systems. The guiding motto will be “cooperation within, competition outside”.

In order to manage an engineering development program of this magnitude, an effective system covering the technical and management aspects needs to be put in place. A sound system engineering approach will have to be followed to ensure the technical health of the program backed by an equally sound project management effort to support it. As the development of FGFA is a major program, it will have to be divided into a number of projects, for which separate project teams will have to be formed. One team would be working on core capabilities development, another on aircraft development, one on avionics development, yet another on facilities development, one on human resource development and so on. There would be specialist teams for development of each system. Depending on the complexity of the systems, these teams would vary in the nature and extent of multi-disciplines. Some teams will be co-located while others would operate across different organizations. Similarly, certain functions will be performed by dedicated project teams while others by matrix teams.

Engineering Management & Support (EMS).

An elaborate plan for development of FGFA and associated technological capabilities will be prepared by DG AvRID. The plan will have to define the different projects within the program and define project teams and their plans in consultation with specialist resource personnel and organizations. The office would be responsible to manage the resources, schedules, risks and stakeholders throughout the program. It would also be responsible for establishing formal system engineering, configuration management and quality assurance processes within the participating teams and organizations. In order to carry out these functions, EMS activities will have to be appropriately organized within an EMS group in DG AvRID Secretariat and manned by qualified personnel: -

(a) Academia Industry Collaboration Office (AICO). For optimum utilization of resources available within academia and industry of the country and abroad.

(b) Systems Engineering Processes Office (SEPO). For training and audit of systems engineering and configuration management processes within participating organizations.

(c) Capability Development Office (CDO). For planning, assisting and tracking capability development encompassing facilities, technology and human resource.

(d) Quality Assurance and Certification Office (QACO). For training and audit of quality assurance and certification standards within participating organizations.

(e) Program Plans Office (PPO). For overall planning, budgeting and resource allocation.

(f) Program Execution Office (PEO). For program execution.

The office of DG AvRID will pursue an active engagement with the public and private sector for expanding the industrial base of the country to meet aviation requirements of Pakistan and to venture into the global aviation market for sustainable technical and economic growth. It will foster international collaboration and linkages to address critical technological gaps. It will also pursue HEC and higher education institutes to ensure that training needs in technologies critical to aviation industry are adequately identified and addressed. It will work with CAE, AU, NUST, IST and other institutes for utilization of their researchers, students, labs and alumni for conducting R&D in appropriate areas. The office will carry out its tasks through the following elements that report to it directly. Additional elements may be added if and when required.

Project AZM.

This project aims to develop a fifth-generation fighter aircraft as per ASR requirements. As mentioned earlier, this is a major undertaking that will require synergetic participation of a large number of organizations and stakeholders. A phased but aggressive approach will be followed to overcome technical challenges as soon as they are identified. A number of challenges like materials, propulsion, sensors, mission systems etc. are already known and risk mitigation plans are being worked out. The strategy is to keep focus of the FGFA team on aircraft development while other elements of AvRID focus on providing the required technologies and systems for project success.

Aviation Design Institute (AvDI).

This institute has been established to develop the core multidisciplinary technologies required for any advanced air vehicle. It is envisaged to bring together experts with varied backgrounds (Aero, Elects, Wpns) and specialties (both Aerospace & Avionics) to work on areas like aerodynamics, antennas, fly-by-wire, payloads, sensor fusion, stealth, structures, etc. The institute undertakes projects that provide solutions in the immediate and short term and in doing so contribute to developing technologies for medium and long-term product development projects like FGF.

Mission Electronics Design Institute (MEDI).

This institute will develop critical technologies like high performance computing boards, advanced avionics interfaces etc. The technologies will be used for design & development of mission computers, flight control computers, etc. Considering the fast pace of development in the field of electronics leading to early obsolescence and the huge amount of data crunching onboard the FGFA, considerable challenges will have to be overcome.

Aero Structures Design Institute (ASDI).

This institute will be responsible for design and analysis of aero structures, including Damage Tolerance Analysis (DTA). It will also interact with the local industry and academia for identifying and developing materials required for aerospace related applications.

Advanced Technologies Centre (ATC).

This Centre will form the PAF element of the Faculty of Aerospace and Aviation Campus AU Kamra and will focus on MS and PhD programs in Aerospace and Avionics disciplines. These programs, in coordination with CAE and other institutes will provide the necessary human resource for programs like FGFA. They will also assist in setting up labs in critical areas and carry out focused research. Short courses in relevant areas will also be arranged.

Flight Test Centre (FTC).

The capability to carry out flight testing of developed systems and platforms will be eventually consolidated into a dedicated flight test Centre. It will assist and coordinate flight testing activities with customers. It would develop the procedures and protocols for flight testing and certification in coordination with development teams and certification authorities, as applicable.

AvRID Capabilities

Aviation City’s evolution transforms PAC Kamra into a teaching industry by bridging itself with co-located Air University Campus. Entire infrastructure of production, upgrade/ overhaul, research & development, qualification and certification would be opened to the students of Air University, thus equipping them with higher academic knowledge and professional skills. These students would be fully fielded in all such disciplines under collaborative supervision of Air University faculty and engineering leadership of the factories.

The multi-discipline research team at Aviation Research, Indigenization & Development (AvRID) Centre will include an effective mix of highly qualified and/or experienced specialists, who would leverage industrial and academic potential available to Kamra. This would put together components of industry and academia to build a high-end research center to enhance indigenization capability. AvRID at Kamra is destined to be the embodiment of this aim.

ghazi52

PDF THINK TANK: ANALYST

- Joined

- Mar 21, 2007

- Messages

- 101,806

- Reaction score

- 106

- Country

- Location

Aircraft Rebuild Factory

The manufacturing resources of ARF are very comprehensive. Availability of highly skilled manpower with ongoing training programme abreast with the technological advancements is also the hallmark of ARF. The core capabilities of factory consist of:-

Canopies and Windshields Manufacturing

Canopy and Windshield Center of Excellence (CoE) is an advanced facility established at ARF providing support primarily to Pakistan Air Force as well as venturing into commercial projects with different inland companies and friendly countries. The core capabilities of this facility include:

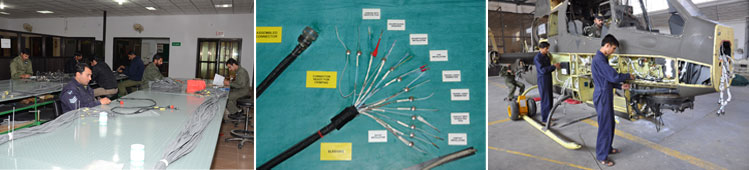

Harness Manufacturing and Rewiring Centre (HM&RC)

HM&RC is a Center of Excellence that is capable of manufacturing aviation standard manufacturing electrical harnesses using the latest materials and techniques. This facility is certified by a number of international companies including SAGEM, DERCO, AXON, CATIC and RAYCHEM.

Propeller & QEC Overhaul

Metrological Centre

Precision Machining Complex

Weapon Rebuild Complex

Heat & Surface Treatment Facility

Sheet Metal Setup

The factory has an elaborate sheet metal facility in which more than 2300 parts of different variants of Chinese aircraft and drop tanks are formed. The basic processes include pressing, bending, turning, crafting and shrinking. State of the art machines including CNC spinning machine, Hydraulic presses (315&70 ton) and Deburring machines are available at the facility.

Rubber and Polymer Parts

ARF has a well-equipped rubber parts manufacturing facility for all the Chinese weapon systems which is not only providing support to Pakistan Air Force, PAC factories but is also meeting the requirements of all GOH related rubber parts manufacturing processes. The facility is capable of producing about 1300 different type of rubber parts (“O” ring, Gasket, Washers, Seals, Spacers etc). The basic processes involve in the manufacturing of rubber parts are:

Spring Manufacturing

In the field of spring manufacturing, the factory has acquired the skill to fulfill the requirement of springs being used during overhauling of an aircraft. These include torsion, tension and compression springs.

Forging and Casting

ARF has a well-equipped forging facility which is sufficient to meet the requirements of all GOH related forging processes. Casting of ferrous and nonferrous parts up to 120 kg in weight can also be carried out.

Aviation Standard Painting / De-painting

Painting and de-painting facility is being utilized for on all the aircraft being overhauled at ARF. This includes internal and external aviation standard painting of various areas of the aircraft.

The manufacturing resources of ARF are very comprehensive. Availability of highly skilled manpower with ongoing training programme abreast with the technological advancements is also the hallmark of ARF. The core capabilities of factory consist of:-

- Canopies & Wind Shields Manufacturing

- Harness Manufacturing

- Propeller & QEC Overhaul

- NDT and Metrology setup

- Precision Machining Complex

- Weapon Rebuild Facility

- Heat & Surface Treatment

- Sheet Metal Setup

- Rubber & Polymer Parts Manufacturing

- Spring Manufacturing

- Forging and Casting

- Aviation Standard Painting

Canopies and Windshields Manufacturing

Canopy and Windshield Center of Excellence (CoE) is an advanced facility established at ARF providing support primarily to Pakistan Air Force as well as venturing into commercial projects with different inland companies and friendly countries. The core capabilities of this facility include:

- Manufacturing, Repairing and overhauling of canopies, windshields and window panels of different fighter, trainer, helicopters and transport fleet aircraft.

- Precise cutting and transferring of holes in acrylic transparencies through 5 Axis CNC milling machine.

- Reverse Engineering of product through 3D scanning, CAD modeling on CATIA software and manufacturing of moulds / dies on CNC machining.

- Computerized Optical Quality inspection of formed transparencies.

Harness Manufacturing and Rewiring Centre (HM&RC)

HM&RC is a Center of Excellence that is capable of manufacturing aviation standard manufacturing electrical harnesses using the latest materials and techniques. This facility is certified by a number of international companies including SAGEM, DERCO, AXON, CATIC and RAYCHEM.

- Manufacturing of harnesses as per OEM Standards for Chinese, French and American range aircraft

- Complete Wiring Conductivity / Insulation Resistance Tests

- Repair / Overhaul of Harnesses

- Re-Wiring solutions for helicopters & small aircraft

Propeller & QEC Overhaul

- Five yearly inspection of Dowty Propeller of SAAB 2000

- Overhaul of C-130 Propellers and QECs

- Complete Disassembly and Rework

- Assembly and Operational Checks

- IOC Repair and Overhaul

Metrological Centre

- Calibration Facilities

- Pressure Metrology

- Absolute Pressure meters / testers, Standard Pressure meters / testers, Vacuum Meters, Hydraulic / Oxygen Pressure Gauges, Air Pressure Gauges, Pressure Sensors and Digital Pressure Meters.

- Length & Geometric Metrology

- Vernier calipers, DTIs, Micrometers, Gauge Blocks, Ring gauges and Plug gauges.

- Electromagnetism Metrology

- AC/DC Volt meters, Amp meters, AC Watt meter Resistance Boxes, Micro ohm meters and Electric Bridges, Microwave signal generator, Oscilloscope, Power meters, Attenuators and Frequency Counters, compass system and Stop Watches.

- Temperature Metrology

- Thermocouple, Thermometers, Temperature Indicators, Controllers and Recorders, Hygrometers.

- Flow Metrology

- Digital Flow Meters, Glass Flow Meters, Mass Flow Meters / Sensors and Fuel Flow Meters / Sensors.

- Mass Metrology

- Weights and Digital / Counter Balances

- Volume Metrology

- Glass Volume Meters like beakers, Pipette, Burette, etc.

- Force Metrology

- Tensile tester, Dynamometer, Hardness tester, Shore Hardness Testers, Force Gauges, Load Sensors, Spring Testers, Torque Wrenches and Torque Testers.

- Testing Facilities

- Non-Destructive Testing Facilities

- Magnetic Particles Testing

- Portable 0~300 A, Stationary equipment 0~10000 A and Magnetic Yoke.

- Penetrant Testing

- Red dye Penetrant and Fluorescent Penetrant testing.

- Radio Graphic Testing

- Portable equipment 0~50 mm of steel, Stationary equipment 0~25 mm of steel.

- Eddy Current Testing

- Surface Scan Eddy Current Testing (SSEC) and Bolt Hole Eddy Current Testing of Aluminum and Steel.

- Ultrasonic Testing

- Ultrasonic inspetion of Aluminium and steel parts by using Ultrasonic Flaw Detector.

- Destructive Testing Facilities

- Physical Properties Testing

- Tensile, Compression, Bending, Shearing, Hardness and Impact Strength.

- Metallographic Testing

- Testing of Macro / Micro Structure of Metallic Materials.

- Chemical Analysis

- Determination of % age of elements in Ferrous and Aluminum Alloys.

- Non-Destructive Testing Facilities

- Aerospace Material Characterization Facility

- Surface Treatment Assessment (Ultrasonic Thickness Meter)

- Determination of Hardness (after sample preparation)

- Chemical Composition Analysis (after sample preparation)

- Metallography

- Microstructure Examination, Evaluation & Interpretation

- Materials Equivalent Study

- Material Heat Treatment Study

Precision Machining Complex

- CAD / CAM based CNC programming (CATIA)

- CNC 3 to 4 Axis Milling Machines

- CNC Turning & Milling Machines

- Coordinate Measuring Machine (CMM) for inspection

- CNC Abrasive Water Jet Cutting Machine

Weapon Rebuild Complex

- Overhaul of Chinese aircraft Alternate Mission Equipment (AMEs) Ejection Seats and aircraft guns

- Overhaul & Qualification of all available Ejector Units (ERUs) of F-7P, F-7PG, K-8 and JF-17 aircraft

- Provision of Depot level maintenance / overhaul support of Armament GSE / GHE

- To undertake Indigenization and development tasks in the domain of Weapon and armament, especially in the field of standoff long-range Precision Guided Munitions and laser Guided Bomb Kits

- Overhaul of F-16 and Mirage Aircraft Alternate Mission Equipment (AMEs)

- Overhaul & Qualification of all available Ejector Units (ERUs) of F-16 and Mirage aircrafts

- Manufacturing of JF-17 Universal Outboard Station Pylon (UOSP)

Heat & Surface Treatment Facility

- Heat Treatment

- Hardening, Tempering, Quenching, Normalizing & Carbonizing

- Surface Treatment

- Zinc, Chromium, Cadmium, Nickle, Tin, Copper, Silver and Shine Nickle Plating

- Hard, Sulphuric Acid, Chromic Acid, Red, Green, Blue & Black Color Anodizing

- Bluing & Acid Pickling

- Oxidation of Aluminum / Magnesium

Sheet Metal Setup

The factory has an elaborate sheet metal facility in which more than 2300 parts of different variants of Chinese aircraft and drop tanks are formed. The basic processes include pressing, bending, turning, crafting and shrinking. State of the art machines including CNC spinning machine, Hydraulic presses (315&70 ton) and Deburring machines are available at the facility.

Rubber and Polymer Parts

ARF has a well-equipped rubber parts manufacturing facility for all the Chinese weapon systems which is not only providing support to Pakistan Air Force, PAC factories but is also meeting the requirements of all GOH related rubber parts manufacturing processes. The facility is capable of producing about 1300 different type of rubber parts (“O” ring, Gasket, Washers, Seals, Spacers etc). The basic processes involve in the manufacturing of rubber parts are:

- Compounding

- Vulcanizing

- Rubberizing

- Cutting

Spring Manufacturing

In the field of spring manufacturing, the factory has acquired the skill to fulfill the requirement of springs being used during overhauling of an aircraft. These include torsion, tension and compression springs.

Forging and Casting

ARF has a well-equipped forging facility which is sufficient to meet the requirements of all GOH related forging processes. Casting of ferrous and nonferrous parts up to 120 kg in weight can also be carried out.

Aviation Standard Painting / De-painting

Painting and de-painting facility is being utilized for on all the aircraft being overhauled at ARF. This includes internal and external aviation standard painting of various areas of the aircraft.

ghazi52

PDF THINK TANK: ANALYST

- Joined

- Mar 21, 2007

- Messages

- 101,806

- Reaction score

- 106

- Country

- Location

Pakistan Certified To Repair SAAB AWACS

Damaged SAAB Erieye undergoing repairs at Pakistan Aeronautical Complex

Pakistan has been certified to build and conduct repair works of Swedish firm SAAB’s Airborne Warning and Control System (AWACS).

“For the first time in history, Swedish SAAB AWACS were built from scratch by another country, even to the disbelief of SAAB itself... who had declared the project technically impossible,” .

SAAB’s Erieye radar system is an Airborne Early Warning and Control (AEW&C) system that uses active electronically scanned array (AESA) technology.

The Erieye Ground Interface Segment is a major component of the software used by the Erieye system.

Similar threads

- Replies

- 6

- Views

- 2K

- Replies

- 22

- Views

- 2K

- Replies

- 0

- Views

- 600