There is great concern about China’s real-estate and infrastructure bubbles. But these are just short-term challenges that China may be able to spend its way out of. The real threat to China’s economy is bigger and longer term: its manufacturing bubble.

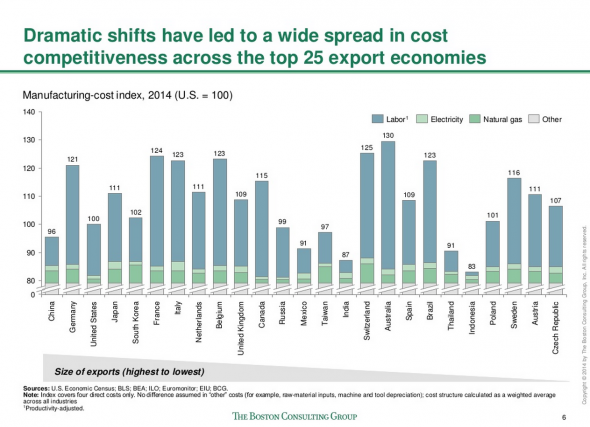

By offering subsidies, cheap labor, and lax regulations and rigging its currency, China was able to seduce American companies to relocate their manufacturing operations there. Millions of American jobs moved to China, and manufacturing became the underpinning of China’s growth and prosperity. But rising labor costs, concerns over government-sponsored I.P. theft, and production time lags are already causing companies such as Dow Chemicals, Caterpillar, GE, and Ford to start moving some manufacturing back to the U.S. from China. Google recently announced that its Nexus Q streaming media player would be made in the U.S., and this put pressure on Apple to start following suit.

But rising costs and political pressure aren’t what’s going to rapidly change the equation. The disruption will come from a set of technologies that are advancing at exponential rates and converging.

These technologies include robotics, artificial intelligence (AI), 3D printing, and nanotechnology. These have been moving slowly so far, but are now beginning to advance exponentially just as computing does. Witness how computing has advanced to the point at which the smart phones we carry in our pockets have more processing power than the super computers of the ’60s—and how the Internet, which also has its origins in the ’60s, went on an exponential growth path about 15 years ago and rapidly changed the way we work, shop, and communicate. That’s what lies ahead for these new technologies.

The robots of today aren’t the Androids or Cylons that we used to see in science-fiction movies, but specialized electro-mechanical devices that are controlled by software and remote controls. As computers become more powerful, so do the abilities of these devices. Robots are now capable of performing surgery, milking cows, doing military reconnaissance and combat, and flying fighter jets. And DIY’ers are lending a helping hand. There are dozens of startups, such as Willow Garage, iRobot, and 9th Sense, selling robot-development kits for university students and open-source communities. They are creating ever more-sophisticated robots and new applications for these. Watch this video of the autonomous flying robots that University of Pennsylvania professor Vijay Kumar created with his students, for example.

The factory assembly that the Chinese are performing is child’s play for the next generation of robots—which will soon become cheaper than human labor. Indeed, one of China’s largest manufacturers, Taiwan-based Foxconn Technology Group, announced last August that it plans to install one million robots within three years to do the work that its workers in China presently do. It found Chinese labor to be too expensive and demanding. The world’s most advanced car, the Tesla Model S, is also being manufactured in Silicon Valley, which is one of the most expensive places in the country. Tesla can afford this because it is using robots to do the assembly.

Then there is artificial intelligence (AI)—software that makes computers do things that, if humans did them, we would call intelligent. We left AI for dead after the hype it created in the ‘80s, but it is alive and kicking—and advancing rapidly. It is powering all sorts of technologies. This is the technology that IBM’s Deep Blue computer used in beating chess grandmaster Garry Kasparov in 1997and that enabled IBM’s Watson to beat TV-show Jeopardy champions in 2011. AI is making it possible to develop self-driving cars, voice-recognition systems such as Apple’s Siri, and the face-recognition software Facebook recently acquired. AI technologies are also finding their way into manufacturing and will allow us to design our own products at home with the aid of AI-powered design assistants.

How will we turn these designs into products? By “printing” them at home or at modern-day Kinko’s: shared public manufacturing facilities such as TechShop, a membership-based manufacturing workshop, using new manufacturing technologies that are now on the horizon.

A type of manufacturing called “additive manufacturing” is making it possible to cost-effectively “print” products. In conventional manufacturing, parts are produced by humans using power-driven machine tools, such as saws, lathes, milling machines, and drill presses, to physically remove material to obtain the shape desired. This is a cumbersome process that becomes more difficult and time-consuming with increasing complexity. In other words, the more complex the product you want to create, the more labor is required and the greater the effort.

In additive manufacturing, parts are produced by melting successive layers of materials based on 3D models—adding materials rather than subtracting them. The “3D printers” that produce these use powered metal, droplets of plastic, and other materials—much like the toner cartridges that go into laser printers. This allows the creation of objects without any sort of tools or fixtures. The process doesn’t produce any waste material, and there is no additional cost for complexity. Just as, in using laser printers, a page filled with graphics doesn’t cost much more than one with text, in using a 3D printer, we can print sophisticated 3D structures for about the cost of a brick.

3D printers can already create physical mechanical devices, medical implants, jewelry, and even clothing. The cheapest 3D printers, which print rudimentary objects, currently sell for between $500 and $1000. Soon, we will have printers for this price that can print toys and household goods. By the end of this decade, we will see 3D printers doing the small-scale production of previously labor-intensive crafts and goods. It is entirely conceivable that in the next decade we start 3D-printing buildings and electronics.

In the next decade, we will see further advances. Engineers and scientists are today developing new types of materials, such as carbon nanotubes, ceramic-matrix nanocomposites, and new carbon fibers. These new materials make it possible to create products that are stronger, lighter, more energy-efficient, and more durable than existing manufactured goods. A new field—molecular manufacturing—will take this one step further and make it possible to program molecules inexpensively, with atomic precision. The materials we use for manufacturing and techniques for production will be nothing like the assembly-based processes that exist in China—and the U.S.—today.

Even if the Chinese automate their factories with AI-powered robots and manufacture 3D printers, it will no longer make sense to ship raw materials all the way to China to have them assembled into finished products and shipped back to the U.S. Manufacturing will once again become a local industry with products being manufactured near raw materials or markets.

So China has many reasons to worry, and manufacturing will undoubtedly return to the U.S.—if not in this decade then early in the next. But the same jobs that left the U.S. won’t come back: they won’t exist. What will the new jobs be? We can only guess. Autodesk CEO Carl Bass says that just as we have created new, higher-paying jobs in every other industrial transition, we will create a new set of industries and professions in this one. Look at the new types of jobs and multi-billion dollar businesses that the Internet and mobile industries created—these came out of nowhere and changed our lives, Bass says.

Carl Bass is one of the leading authorities on 3D printing and digital manufacturing, and I share his optimism that we will create an era of abundance. But I worry if we will create the new jobs fast enough and distribute the prosperity. Carl and I discussed this at Singularity University a few months ago. And I also discussed China manufacturing with The Economist China bureau chief, Vijay Vaitheeswaran. You can find these videos below.

The End of Chinese Manufacturing and Rebirth of U.S. Industry - Forbes

By offering subsidies, cheap labor, and lax regulations and rigging its currency, China was able to seduce American companies to relocate their manufacturing operations there. Millions of American jobs moved to China, and manufacturing became the underpinning of China’s growth and prosperity. But rising labor costs, concerns over government-sponsored I.P. theft, and production time lags are already causing companies such as Dow Chemicals, Caterpillar, GE, and Ford to start moving some manufacturing back to the U.S. from China. Google recently announced that its Nexus Q streaming media player would be made in the U.S., and this put pressure on Apple to start following suit.

But rising costs and political pressure aren’t what’s going to rapidly change the equation. The disruption will come from a set of technologies that are advancing at exponential rates and converging.

These technologies include robotics, artificial intelligence (AI), 3D printing, and nanotechnology. These have been moving slowly so far, but are now beginning to advance exponentially just as computing does. Witness how computing has advanced to the point at which the smart phones we carry in our pockets have more processing power than the super computers of the ’60s—and how the Internet, which also has its origins in the ’60s, went on an exponential growth path about 15 years ago and rapidly changed the way we work, shop, and communicate. That’s what lies ahead for these new technologies.

The robots of today aren’t the Androids or Cylons that we used to see in science-fiction movies, but specialized electro-mechanical devices that are controlled by software and remote controls. As computers become more powerful, so do the abilities of these devices. Robots are now capable of performing surgery, milking cows, doing military reconnaissance and combat, and flying fighter jets. And DIY’ers are lending a helping hand. There are dozens of startups, such as Willow Garage, iRobot, and 9th Sense, selling robot-development kits for university students and open-source communities. They are creating ever more-sophisticated robots and new applications for these. Watch this video of the autonomous flying robots that University of Pennsylvania professor Vijay Kumar created with his students, for example.

The factory assembly that the Chinese are performing is child’s play for the next generation of robots—which will soon become cheaper than human labor. Indeed, one of China’s largest manufacturers, Taiwan-based Foxconn Technology Group, announced last August that it plans to install one million robots within three years to do the work that its workers in China presently do. It found Chinese labor to be too expensive and demanding. The world’s most advanced car, the Tesla Model S, is also being manufactured in Silicon Valley, which is one of the most expensive places in the country. Tesla can afford this because it is using robots to do the assembly.

Then there is artificial intelligence (AI)—software that makes computers do things that, if humans did them, we would call intelligent. We left AI for dead after the hype it created in the ‘80s, but it is alive and kicking—and advancing rapidly. It is powering all sorts of technologies. This is the technology that IBM’s Deep Blue computer used in beating chess grandmaster Garry Kasparov in 1997and that enabled IBM’s Watson to beat TV-show Jeopardy champions in 2011. AI is making it possible to develop self-driving cars, voice-recognition systems such as Apple’s Siri, and the face-recognition software Facebook recently acquired. AI technologies are also finding their way into manufacturing and will allow us to design our own products at home with the aid of AI-powered design assistants.

How will we turn these designs into products? By “printing” them at home or at modern-day Kinko’s: shared public manufacturing facilities such as TechShop, a membership-based manufacturing workshop, using new manufacturing technologies that are now on the horizon.

A type of manufacturing called “additive manufacturing” is making it possible to cost-effectively “print” products. In conventional manufacturing, parts are produced by humans using power-driven machine tools, such as saws, lathes, milling machines, and drill presses, to physically remove material to obtain the shape desired. This is a cumbersome process that becomes more difficult and time-consuming with increasing complexity. In other words, the more complex the product you want to create, the more labor is required and the greater the effort.

In additive manufacturing, parts are produced by melting successive layers of materials based on 3D models—adding materials rather than subtracting them. The “3D printers” that produce these use powered metal, droplets of plastic, and other materials—much like the toner cartridges that go into laser printers. This allows the creation of objects without any sort of tools or fixtures. The process doesn’t produce any waste material, and there is no additional cost for complexity. Just as, in using laser printers, a page filled with graphics doesn’t cost much more than one with text, in using a 3D printer, we can print sophisticated 3D structures for about the cost of a brick.

3D printers can already create physical mechanical devices, medical implants, jewelry, and even clothing. The cheapest 3D printers, which print rudimentary objects, currently sell for between $500 and $1000. Soon, we will have printers for this price that can print toys and household goods. By the end of this decade, we will see 3D printers doing the small-scale production of previously labor-intensive crafts and goods. It is entirely conceivable that in the next decade we start 3D-printing buildings and electronics.

In the next decade, we will see further advances. Engineers and scientists are today developing new types of materials, such as carbon nanotubes, ceramic-matrix nanocomposites, and new carbon fibers. These new materials make it possible to create products that are stronger, lighter, more energy-efficient, and more durable than existing manufactured goods. A new field—molecular manufacturing—will take this one step further and make it possible to program molecules inexpensively, with atomic precision. The materials we use for manufacturing and techniques for production will be nothing like the assembly-based processes that exist in China—and the U.S.—today.

Even if the Chinese automate their factories with AI-powered robots and manufacture 3D printers, it will no longer make sense to ship raw materials all the way to China to have them assembled into finished products and shipped back to the U.S. Manufacturing will once again become a local industry with products being manufactured near raw materials or markets.

So China has many reasons to worry, and manufacturing will undoubtedly return to the U.S.—if not in this decade then early in the next. But the same jobs that left the U.S. won’t come back: they won’t exist. What will the new jobs be? We can only guess. Autodesk CEO Carl Bass says that just as we have created new, higher-paying jobs in every other industrial transition, we will create a new set of industries and professions in this one. Look at the new types of jobs and multi-billion dollar businesses that the Internet and mobile industries created—these came out of nowhere and changed our lives, Bass says.

Carl Bass is one of the leading authorities on 3D printing and digital manufacturing, and I share his optimism that we will create an era of abundance. But I worry if we will create the new jobs fast enough and distribute the prosperity. Carl and I discussed this at Singularity University a few months ago. And I also discussed China manufacturing with The Economist China bureau chief, Vijay Vaitheeswaran. You can find these videos below.

The End of Chinese Manufacturing and Rebirth of U.S. Industry - Forbes