The SC

ELITE MEMBER

- Joined

- Feb 13, 2012

- Messages

- 32,233

- Reaction score

- 21

- Country

- Location

GaN Technology for Radars

Keywords: GaN, gallium nitride, microwave devices, MMICs

Abstract

Microwave GaN technology is now in production and

poised to revolutionize many of today’s radar and

communication systems. Simultaneously, mm-wave GaN

processes are rapidly being matured to meet the growing

needs of high power and efficiency, at higher frequencies.

In this paper, we present an overview of GaN

development, focusing on reliability and affordability for

defense applications.

I

NTRODUCTION

His

torically, performance improvements afforded by new

microwave semiconductor technologies such as GaAs

MESFETs and PHEMTs have been evolutionary, resulting

in incrementally more power density, gain, or noise figure.

Gallium Nitride (GaN) technology, however, is truly

revolutionary, resulting in dramatic (>5X) improvements in

RF power density. The revolutionary power improvements

afforded by GaN are now being realized in state-of-the-art

monolithic

microwave integrated circuits (MMICs)

assembled in Transmit/Receive (T/R) modules, enabling the

next generation of radar and communication systems.

High power semiconductors play an important role in

radar performance. In a phased array radar, the RF energy is

distributed to each element, phase shifted and then amplified

before being radiated. The final amplification of the RF

signal at each element is performed by the power amplifier.

Traditionally, gallium arsenide (GaAs) has been the

semiconductor of choice for efficiently amplifying this

signal, creating the desired output power. Throughout the

1990’s, Raytheon and others pioneered the insertion of

GaAs-based MMICs into phased array radars, providing

enabling system capabilities. As the performance

requirements of these military systems have increased to

meet the ever growing threats, so too have the power and

efficiency requirements for the power amplifiers. Over that

time, GaAs performance was stretched from the unit gate

power density of 0.5 watt per millimeter of transistor

periphery to 1.5 W/mm by increasing the drain voltage from

5V to nearly 24V. GaN, however, continued to make

dramatic performance and maturity improvements, quickly

surpassing GaAs’ capability in power, efficiency, thermal

spreading, cost effectiveness and frequency coverage

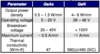

(Table 1).

Today, with the development of microwave GaN

complete, the power, efficiency and bandwidth performance

of GaN-based MMICs is unsurpassed, revolutionizing the

design of radars by creating not only higher performance but

also lower system cost. With over 5 W/mm of power

density, GaN RF amplifiers can provide more than 5X the

power per element of GaAs, in the same square millimeter

area footprint. Fewer high power GaN MMICs can be used

to replace many low power GaAs MMICs, or alternatively,

equal power GaN chips can be made dramatically smaller

than their GaAs equivalent. Both approaches reduce overall

system costs while enabling size-constrained systems. The

higher drain current that GaN offers makes the broadband

matching of high power MMICs simpler and more efficient

than GaAs, while the 7-8X improvement in the thermal

conductivity provided by the high conductivity SiC substrate

enables amplifier cooling. This higher efficiency, achieved

at high power, combined with better thermal dissipation, is a

game changer for solid state electronic warfare systems.

Finally, the wide band gap intrinsic to GaN material

provides large critical breakdown fields and voltages,

making a more robust amplifier, which eases T/R module

and system implementation.

Table 1. GaN vs. GaAs Comparison

Parameter

GaAs

GaN

Output power

density

0.5 – 1.5 W/mm

4– 8 W/mm

Operating voltage

5 – 20 V

28 – 48 V

Breakdown

voltage

20 – 40V

> 100V

Maximum current

~ 0.5 A/mm

~1 A/mm

Thermal

conductivity

(W/m-K)

47

390(z)/490 (SiC)

This paper will review the advances in GaN device

development, starting in the 1990’s with the first transistor

to its production status today. DC Arrhenius reliability data

CS MANTECH Conference, April 23rd - 26th, 2012, Boston, Massachusetts, USA

and RF operating life measurements of Raytheon’s

microwave process will also be presented. Finally, sample

MMIC designs will be reviewed, along with system insertion

considerations, including cost and thermal constraints.

G

A

N

D

EVELOPMENT

The development of GaN semiconductors began more

than 30 years ago, driven by their unique properties

seemingly ideal for high-power microwave devices based on

their high theoretical breakdown field and high saturated

electron velocity. But at that time, the gallium nitride

material quality was insufficient to produce microwave RF

transistors. This all began to change in the early 1990s,

Figure 1, when researchers used gallium nitride to fabricate

the world’s first green, blue, violet and white light-emitting

diodes (LEDs) [1,2]. This breakthrough drove forward a

rapid improvement in GaN material quality. Now, these

LEDs can be found in traffic lights, TVs and flashlights.

Another obstacle to the development of GaN transistors

was the lack of an inexpensive substrate material.

Traditionally, the substrate material of the transistor is the

same material as the transistor itself, but, to date, researchers

have been unable to grow large area, high quality GaN

substrates. Researchers first turned to growing GaN

transistors on sapphire substrates, and in 1996 demonstrated

the first microwave GaN power transistors. The sapphire

substrates are low cost and widely available; however, their

poor thermal conductivity and non-ideal lattice match to

GaN limited the performance of the transistors. Semi-

insulating silicon carbide (SiC) substrate proved a better

choice with a good lattice match to GaN and an excellent

thermal conductivity. The only drawback was that silicon

carbide substrates were only available in small sizes (50 mm

diameter) and were very expensive (100 times the price of

GaAs) in the late 1990s. The last 10 years have seen a rapid

improvement in the size, quality and cost of the silicon

carbide substrates. Today, Raytheon’s production GaN

process uses 100 mm (4-inch) diameter SiC substrates [3,4].

Figure 1. Timeline of GaN development

R

ELIABILITY

Over the last six years, through the testing of hundreds of

transistors and MMICs, Raytheon’s 4” microwave GaN

processes has demonstrated the required reliability for

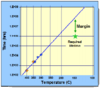

military systems. Figure 2 shows the DC Arrhenius results

of a population of ~70 devices tested at five highly

accelerated temperatures and 28V bias. The activation

energy is ~1.7eV with a median time to failure (MTTF) at

150C of ~10

8

hours [5], exceeding the 10

6

hr standard.

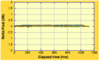

Figure 3 shows no change in output power of twelve X-band

MMICs operating ~3-4 dB compressed at 28V for more than

1,000 hours. Channel temperatures are estimated to be

~150C-200C during this RF operating test. Additional

testing for more than 15,000 hours on X-band MMICs has

yielded similar results.

Figure 2. DC Arrhenius results of accelerated testing of

10x125um GaN transistors operating at 28V.

-2

-1.5

-1

-0.5

0

0.5

1

1.5

2

0

200

400

600

800

1000

1200

Delta Pout (dB)

Elapsed time (hrs)

Figure 3. A dozen X-band MMICs demonstrating no change

in output power over 1,000 hrs of RF operation at 28V.

MMIC

S

Raytheon has developed MMICs using both microstrip

and coplanar waveguide (CPW) circuit design techniques,

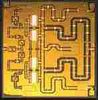

each of which offers advantages. Figure 4 shows two low

frequency MMICs designed and fabricated using both

topologies, and which demonstrated similar performance and

size. The CPW process is lower in cost and higher yielding

since it eliminates the backside grinding and via process, but

at higher frequencies the output matching network becomes

CS MANTECH Conference, April 23rd - 26th, 2012, Boston, Massachusetts, USA

higher loss using this technique. In a face-up module

implementation, the CPW design also offers a superior

conduction path due the heat spreading of the thick SiC

material. The microstrip MMIC offers slightly lower loss

and is easier to design, allowing for faster design iterations.

Figure 4. Fabricated low frequency Microstrip (left) and

CPW (right) GaN MMICs

With the maturation of GaN in the lower RF frequency

operating range, development focus has now shifted to GaN

at mm-wave frequencies. At the extreme of the mm-wave

RF frequency band, we have fabricated a 3-stage W-band

GaN MMIC using a 2mil thick, microstrip topology

operating at 17V [6]. This compact MMIC is less than

2.5mm

2

and has 16 dB of small signal gain at 91 GHz.

Un

der large signal compressed operation, the MMIC

delivered 1.2W of output power and 20% PAE. These

results compare favorably to the best efficiency

demonstrated at this frequency using high gain, lower power

InP technology, but at many multiples of output power.

S

YSTEM

I

NSERTIONS

G

aN offers a number of advantages for next generation

radars and jammers, as well as upgrades to existing GaAs or

tube-based systems. Fewer high power GaN MMICs can be

used to replace either many low power GaAs

MMICs/modules or a single, often unreliable, high power

tube, reducing overall cost while improving system

reliability. For a fixed power level, a GaN MMIC can be

1/3-1/4 the size of an equivalent power GaAs MMIC due to

the higher power density transistors. While the GaN

starting material (GaN on SiC) is considerably more

expensive than GaAs, the reduced area to generate similar

power allows the GaN solution to be less expensive. For

example, if the finished GaN wafer (including material)

costs 2X that of GaAs, but yet the GaN MMIC is 1/3-1/4 the

size of the GaAs MMIC, the resulting GaN solution is only

50-66% the dollars per RF Watt generated. A GaN-based

system also provides additional benefits over GaAs at the

system level by reducing overall module count, a major

system cost driver, and the higher operating voltage

improves the DC to RF conversion efficiency, reducing

prime power and life cycle costs. For systems where

maximum power per unit cell is desired, GaN offers ~5X

power improvement in the same mm

2

as GaAs, enabling

ma

ny space-constrained systems.

C

ONCLUSIONS

G

aN material, processing, MMIC design and system

insertion has matured greatly over the last decade, driven by

its ability to increase the capability of RF systems, while

reducing their cost. Today, GaN is quickly becoming the

power amplification standard for all RF systems and is being

assembled into modules and radars (Figure 5).

http://csmantech.pairserver.com/newsite/gaasmantech/Digests/2012/papers/3.2.011.pdf

Keywords: GaN, gallium nitride, microwave devices, MMICs

Abstract

Microwave GaN technology is now in production and

poised to revolutionize many of today’s radar and

communication systems. Simultaneously, mm-wave GaN

processes are rapidly being matured to meet the growing

needs of high power and efficiency, at higher frequencies.

In this paper, we present an overview of GaN

development, focusing on reliability and affordability for

defense applications.

I

NTRODUCTION

His

torically, performance improvements afforded by new

microwave semiconductor technologies such as GaAs

MESFETs and PHEMTs have been evolutionary, resulting

in incrementally more power density, gain, or noise figure.

Gallium Nitride (GaN) technology, however, is truly

revolutionary, resulting in dramatic (>5X) improvements in

RF power density. The revolutionary power improvements

afforded by GaN are now being realized in state-of-the-art

monolithic

microwave integrated circuits (MMICs)

assembled in Transmit/Receive (T/R) modules, enabling the

next generation of radar and communication systems.

High power semiconductors play an important role in

radar performance. In a phased array radar, the RF energy is

distributed to each element, phase shifted and then amplified

before being radiated. The final amplification of the RF

signal at each element is performed by the power amplifier.

Traditionally, gallium arsenide (GaAs) has been the

semiconductor of choice for efficiently amplifying this

signal, creating the desired output power. Throughout the

1990’s, Raytheon and others pioneered the insertion of

GaAs-based MMICs into phased array radars, providing

enabling system capabilities. As the performance

requirements of these military systems have increased to

meet the ever growing threats, so too have the power and

efficiency requirements for the power amplifiers. Over that

time, GaAs performance was stretched from the unit gate

power density of 0.5 watt per millimeter of transistor

periphery to 1.5 W/mm by increasing the drain voltage from

5V to nearly 24V. GaN, however, continued to make

dramatic performance and maturity improvements, quickly

surpassing GaAs’ capability in power, efficiency, thermal

spreading, cost effectiveness and frequency coverage

(Table 1).

Today, with the development of microwave GaN

complete, the power, efficiency and bandwidth performance

of GaN-based MMICs is unsurpassed, revolutionizing the

design of radars by creating not only higher performance but

also lower system cost. With over 5 W/mm of power

density, GaN RF amplifiers can provide more than 5X the

power per element of GaAs, in the same square millimeter

area footprint. Fewer high power GaN MMICs can be used

to replace many low power GaAs MMICs, or alternatively,

equal power GaN chips can be made dramatically smaller

than their GaAs equivalent. Both approaches reduce overall

system costs while enabling size-constrained systems. The

higher drain current that GaN offers makes the broadband

matching of high power MMICs simpler and more efficient

than GaAs, while the 7-8X improvement in the thermal

conductivity provided by the high conductivity SiC substrate

enables amplifier cooling. This higher efficiency, achieved

at high power, combined with better thermal dissipation, is a

game changer for solid state electronic warfare systems.

Finally, the wide band gap intrinsic to GaN material

provides large critical breakdown fields and voltages,

making a more robust amplifier, which eases T/R module

and system implementation.

Table 1. GaN vs. GaAs Comparison

Parameter

GaAs

GaN

Output power

density

0.5 – 1.5 W/mm

4– 8 W/mm

Operating voltage

5 – 20 V

28 – 48 V

Breakdown

voltage

20 – 40V

> 100V

Maximum current

~ 0.5 A/mm

~1 A/mm

Thermal

conductivity

(W/m-K)

47

390(z)/490 (SiC)

This paper will review the advances in GaN device

development, starting in the 1990’s with the first transistor

to its production status today. DC Arrhenius reliability data

CS MANTECH Conference, April 23rd - 26th, 2012, Boston, Massachusetts, USA

and RF operating life measurements of Raytheon’s

microwave process will also be presented. Finally, sample

MMIC designs will be reviewed, along with system insertion

considerations, including cost and thermal constraints.

G

A

N

D

EVELOPMENT

The development of GaN semiconductors began more

than 30 years ago, driven by their unique properties

seemingly ideal for high-power microwave devices based on

their high theoretical breakdown field and high saturated

electron velocity. But at that time, the gallium nitride

material quality was insufficient to produce microwave RF

transistors. This all began to change in the early 1990s,

Figure 1, when researchers used gallium nitride to fabricate

the world’s first green, blue, violet and white light-emitting

diodes (LEDs) [1,2]. This breakthrough drove forward a

rapid improvement in GaN material quality. Now, these

LEDs can be found in traffic lights, TVs and flashlights.

Another obstacle to the development of GaN transistors

was the lack of an inexpensive substrate material.

Traditionally, the substrate material of the transistor is the

same material as the transistor itself, but, to date, researchers

have been unable to grow large area, high quality GaN

substrates. Researchers first turned to growing GaN

transistors on sapphire substrates, and in 1996 demonstrated

the first microwave GaN power transistors. The sapphire

substrates are low cost and widely available; however, their

poor thermal conductivity and non-ideal lattice match to

GaN limited the performance of the transistors. Semi-

insulating silicon carbide (SiC) substrate proved a better

choice with a good lattice match to GaN and an excellent

thermal conductivity. The only drawback was that silicon

carbide substrates were only available in small sizes (50 mm

diameter) and were very expensive (100 times the price of

GaAs) in the late 1990s. The last 10 years have seen a rapid

improvement in the size, quality and cost of the silicon

carbide substrates. Today, Raytheon’s production GaN

process uses 100 mm (4-inch) diameter SiC substrates [3,4].

Figure 1. Timeline of GaN development

R

ELIABILITY

Over the last six years, through the testing of hundreds of

transistors and MMICs, Raytheon’s 4” microwave GaN

processes has demonstrated the required reliability for

military systems. Figure 2 shows the DC Arrhenius results

of a population of ~70 devices tested at five highly

accelerated temperatures and 28V bias. The activation

energy is ~1.7eV with a median time to failure (MTTF) at

150C of ~10

8

hours [5], exceeding the 10

6

hr standard.

Figure 3 shows no change in output power of twelve X-band

MMICs operating ~3-4 dB compressed at 28V for more than

1,000 hours. Channel temperatures are estimated to be

~150C-200C during this RF operating test. Additional

testing for more than 15,000 hours on X-band MMICs has

yielded similar results.

Figure 2. DC Arrhenius results of accelerated testing of

10x125um GaN transistors operating at 28V.

-2

-1.5

-1

-0.5

0

0.5

1

1.5

2

0

200

400

600

800

1000

1200

Delta Pout (dB)

Elapsed time (hrs)

Figure 3. A dozen X-band MMICs demonstrating no change

in output power over 1,000 hrs of RF operation at 28V.

MMIC

S

Raytheon has developed MMICs using both microstrip

and coplanar waveguide (CPW) circuit design techniques,

each of which offers advantages. Figure 4 shows two low

frequency MMICs designed and fabricated using both

topologies, and which demonstrated similar performance and

size. The CPW process is lower in cost and higher yielding

since it eliminates the backside grinding and via process, but

at higher frequencies the output matching network becomes

CS MANTECH Conference, April 23rd - 26th, 2012, Boston, Massachusetts, USA

higher loss using this technique. In a face-up module

implementation, the CPW design also offers a superior

conduction path due the heat spreading of the thick SiC

material. The microstrip MMIC offers slightly lower loss

and is easier to design, allowing for faster design iterations.

Figure 4. Fabricated low frequency Microstrip (left) and

CPW (right) GaN MMICs

With the maturation of GaN in the lower RF frequency

operating range, development focus has now shifted to GaN

at mm-wave frequencies. At the extreme of the mm-wave

RF frequency band, we have fabricated a 3-stage W-band

GaN MMIC using a 2mil thick, microstrip topology

operating at 17V [6]. This compact MMIC is less than

2.5mm

2

and has 16 dB of small signal gain at 91 GHz.

Un

der large signal compressed operation, the MMIC

delivered 1.2W of output power and 20% PAE. These

results compare favorably to the best efficiency

demonstrated at this frequency using high gain, lower power

InP technology, but at many multiples of output power.

S

YSTEM

I

NSERTIONS

G

aN offers a number of advantages for next generation

radars and jammers, as well as upgrades to existing GaAs or

tube-based systems. Fewer high power GaN MMICs can be

used to replace either many low power GaAs

MMICs/modules or a single, often unreliable, high power

tube, reducing overall cost while improving system

reliability. For a fixed power level, a GaN MMIC can be

1/3-1/4 the size of an equivalent power GaAs MMIC due to

the higher power density transistors. While the GaN

starting material (GaN on SiC) is considerably more

expensive than GaAs, the reduced area to generate similar

power allows the GaN solution to be less expensive. For

example, if the finished GaN wafer (including material)

costs 2X that of GaAs, but yet the GaN MMIC is 1/3-1/4 the

size of the GaAs MMIC, the resulting GaN solution is only

50-66% the dollars per RF Watt generated. A GaN-based

system also provides additional benefits over GaAs at the

system level by reducing overall module count, a major

system cost driver, and the higher operating voltage

improves the DC to RF conversion efficiency, reducing

prime power and life cycle costs. For systems where

maximum power per unit cell is desired, GaN offers ~5X

power improvement in the same mm

2

as GaAs, enabling

ma

ny space-constrained systems.

C

ONCLUSIONS

G

aN material, processing, MMIC design and system

insertion has matured greatly over the last decade, driven by

its ability to increase the capability of RF systems, while

reducing their cost. Today, GaN is quickly becoming the

power amplification standard for all RF systems and is being

assembled into modules and radars (Figure 5).

http://csmantech.pairserver.com/newsite/gaasmantech/Digests/2012/papers/3.2.011.pdf