Hamartia Antidote

ELITE MEMBER

- Joined

- Nov 17, 2013

- Messages

- 35,188

- Reaction score

- 30

- Country

- Location

Stoke Space / 100% reusable rockets / USA

Stoke Space to build SpaceX Raptor engine's first real competitor

Seattle startup Stoke Space has revealed plans to develop an efficient rocket engine similar to the Raptors that power SpaceX's Starship.

Seattle startup Stoke Space has revealed plans to develop an efficient rocket engine similar to the Raptors that power SpaceX’s Starship.

Formed in October 2019, Stoke Space secured its first significant round of funding – $9.1 million – less than three years ago.

At that time, CEO and co-founder Andy Lapsa says that the startup had just five employees, no permanent workspace, and a “barren field” for a test site. Within 18 months, Stoke Space had turned that empty field into an impressive test facility, conducted numerous component tests, and assembled its first full-scale rocket engine – an exotic UFO-like device unlike any seen before.

It also raised another $65 million – enough funding to begin earnestly developing a potentially revolutionary rocket capable of launching more than 1.65 tons (~3600 lb) into orbit for less than half a million dollars. To realize that extremely ambitious goal, Stoke Space has taken the even more ambitious step of attempting to make the first rocket it develops fully reusable. Simultaneously, the company has incorporated several exotic technologies into that rocket, recently culminating in a surprise announcement that it will attempt to develop one of the most difficult types of engines to power that rocket’s booster stage.

FULL-FLOW STAGED COMBUSTION

At the end of an extended interview and tour with YouTuber Tim Dodd (The Everyday Astronaut), CEO Andy Lapsa revealed that Stoke Space has decided to build a full-flow staged combustion (FFSC) engine for the first stage of its reusable rocket. FFSC is the most efficient type of combustion cycle available for a chemical bipropellant rocket engine, but it’s also the most difficult to develop.A full-flow engine attempts to squeeze every possible ounce of performance out of the propellant it consumes. The most powerful and efficient chemical rocket engines must consume huge volumes of propellant in a short amount of time without destroying the launch vehicle they’re attached to. To create pressure and spin the pumps that are needed to feed that propellant into their main combustion chamber, engines often burn a small amount of propellant in a separate gas generator or preburner. Gas-generator engines vent that exhaust overboard, reducing efficiency but making for a much simpler design. Staged-combustion engines use preburners to create gas that pumps liquid propellant, and that exhaust gas is eventually injected into the main combustion chamber.

Full-flow staged combustion sets itself apart by having two separate pumps and preburners for oxidizer and fuel. Unlike simpler variants of staged combustion, FFSC engines turn all of their propellant into gas before injecting it into the combustion chamber. That hot gas increases the heat of combustion and the pressure inside the combustion chamber, ensuring that virtually all of the propellant that flows through the engine is combusted and turned into thrust as efficiently as possible. FFSC is exceptionally difficult because of the extra-high temperatures and pressures it requires, as well as the need for an oxygen-rich preburner and pump. In a high-pressure, hot-oxygen environment, virtually anything imaginable – including most metals – will spontaneously combust.

The first booster engine Stoke Space ever attempts to build will be a reusable full-flow staged combustion engine powered by liquid methane and liquid oxygen – essentially a smaller version of SpaceX’s Raptor. Stoke’s booster is otherwise familiar and features deployable landing legs like SpaceX’s Falcon boosters. Lapsa says it will likely also have grid fins.

REUSING THE UPPER STAGE

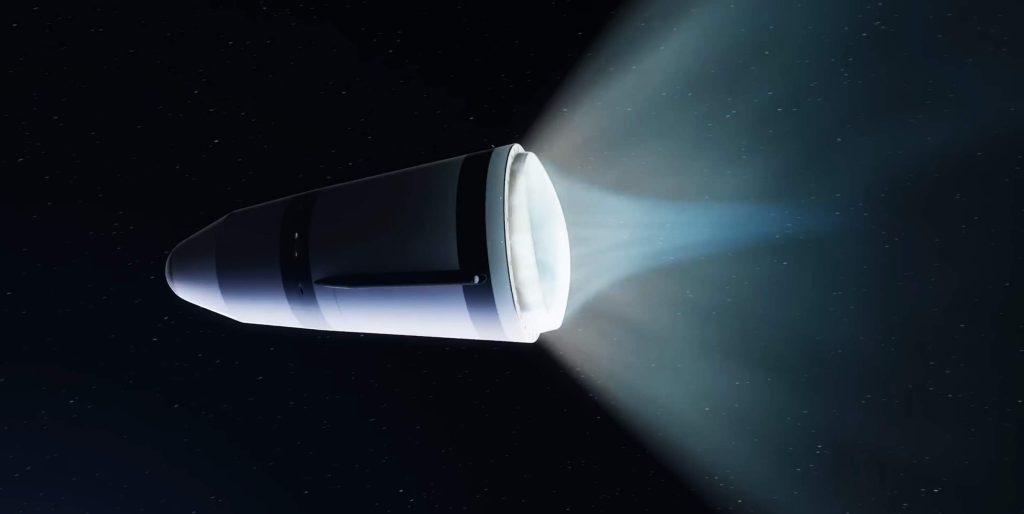

In some ways, the upper stage of Stoke’s first rocket is even more ambitious. Powered by hydrogen and oxygen propellant, Stoke has designed a conical capsule-like upper stage with an integral fairing. The upper stage’s propulsion is exotic and unique. A large pump will feed propellant to up to 30 combustion chambers distributed around the rim of its heat shield. The exhaust coming from those 30 chambers will expand and partially push against the upper stage’s equally exotic metallic, liquid-cooled heat shield. That expansion against the heat shield improves the efficiency of the upper stage and means that its engine will technically be an aerospike. The upper stage prepares for reentry.

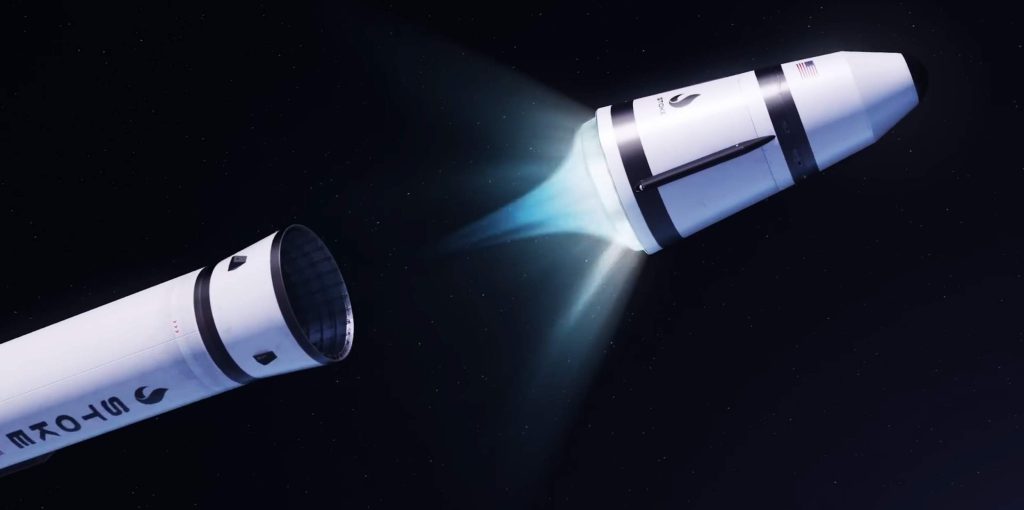

The upper stage prepares for reentry. The upper stage separates from the booster.

The upper stage separates from the booster.

The upper stage touches down.

The upper stage touches down. Individual Stoke thrusters.

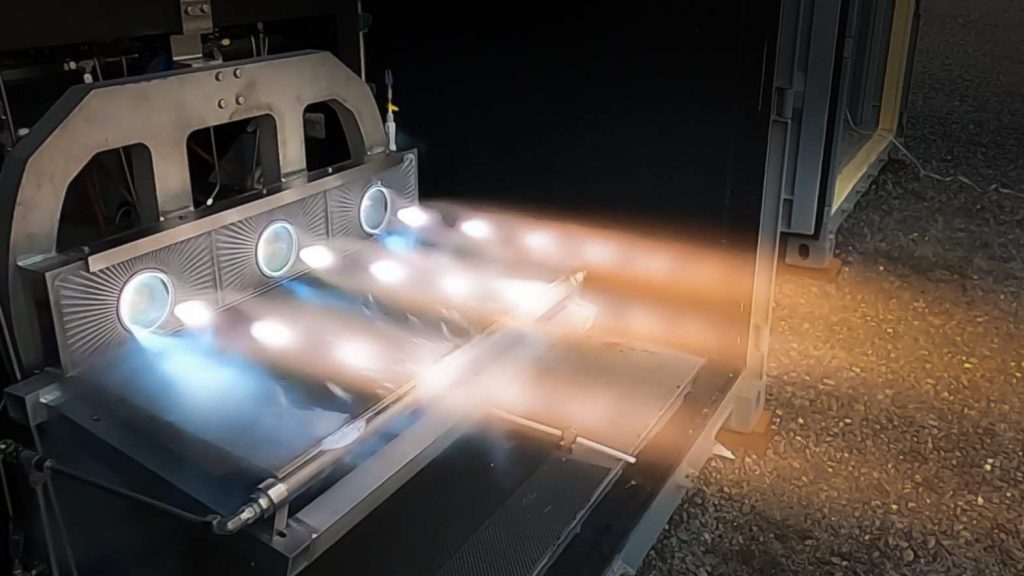

Individual Stoke thrusters. A 15-chamber static fire.

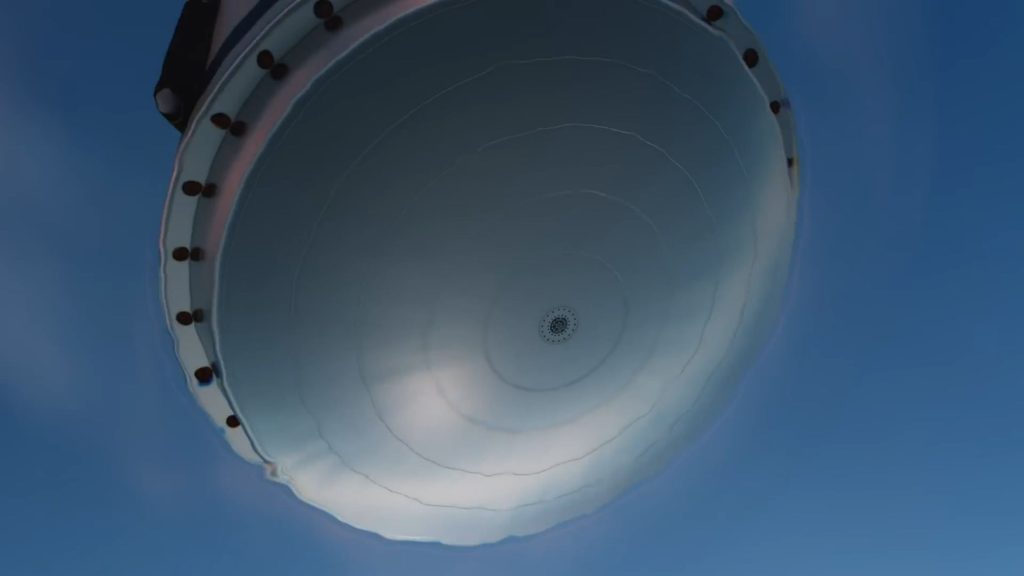

A 15-chamber static fire. A prototype of the upper stage heat shield and engine.

A prototype of the upper stage heat shield and engine. A prototype of the upper stage tanks. (Everyday Astronaut)

A prototype of the upper stage tanks. (Everyday Astronaut)Stoke has already begun testing a full-scale version of the upper stage’s UFO-like rocket engine with 15 combustion chambers. Since testing began in the second half of 2022, Stoke has completed dozens of static fires. Everyday Astronaut’s tour also revealed that the startup has made significant progress fabricating and assembling its first full-scale upper stage prototype – tanks, nosecone, heat shield, engine, and all.

Reminiscent of SpaceX’s Grasshopper and Starhopper campaigns, Stoke plans to conduct hop tests with that prototype if it makes it through qualification testing. On February 7th, Stoke also revealed that it’s begun testing a crucial component of its full-flow booster engine. All told, Stoke Space is making progress at a remarkable pace and continues to tackle the hardest problems. The startup has also avoided widely publicizing any specific deadlines, instead choosing to let hardware and tangible results speak for themselves. Only time will tell if that approach pays off, but Stoke is off to an exceptionally impressive start in an industry full of impressive rocket startups.