cabatli_53

ELITE MEMBER

- Joined

- Feb 20, 2008

- Messages

- 12,808

- Reaction score

- 62

- Country

- Location

T-38 ARI modernization !!!

Under ARI program, the avionics, that are standard in the T-38 trainers, will be replaced with state-of-the-art digital technology. TAI is responsible for upgrading T-38 aircraft with the following systems/equipment as well as providing long lasting logistics support.

There will be 13 new systems integrated to the aircraft. These are;

* Head Up Display (HUD),

* Multifunction Color Display (MFCD),

* Digital Video Data recorder / Data transfer system (DVDR/DTS),

* Hands on throttle and stick(HOTAS),

* Intercommunication system(ICS),

* V/UHF Communication System

* Engine Flight Instrument(EFI),

* Cockpit TV System(CTVS),

* VOR/ILS,

* Avionic Activation Panel (AAP),

* Common Control Computer Panel (CCC)

Central Control Computer, embedded with Operational Flight Program (OFP) and NDBS (No Drop Bomb Scoring System) will be designed, developed and qualified by national capabilities.

During the program, Mission Planning and Ground Station (MPGS) and De-brief Software will be developed.

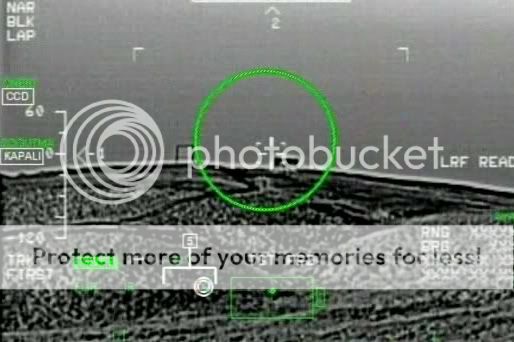

Left side picture belongs to T-38 Arı's new mission computer tests...

T-38 cockpit After modernization

Before modernization

Under ARI program, the avionics, that are standard in the T-38 trainers, will be replaced with state-of-the-art digital technology. TAI is responsible for upgrading T-38 aircraft with the following systems/equipment as well as providing long lasting logistics support.

There will be 13 new systems integrated to the aircraft. These are;

* Head Up Display (HUD),

* Multifunction Color Display (MFCD),

* Digital Video Data recorder / Data transfer system (DVDR/DTS),

* Hands on throttle and stick(HOTAS),

* Intercommunication system(ICS),

* V/UHF Communication System

* Engine Flight Instrument(EFI),

* Cockpit TV System(CTVS),

* VOR/ILS,

* Avionic Activation Panel (AAP),

* Common Control Computer Panel (CCC)

Central Control Computer, embedded with Operational Flight Program (OFP) and NDBS (No Drop Bomb Scoring System) will be designed, developed and qualified by national capabilities.

During the program, Mission Planning and Ground Station (MPGS) and De-brief Software will be developed.

Left side picture belongs to T-38 Arı's new mission computer tests...

T-38 cockpit After modernization

Before modernization