Lifting vortices of double delta wing. At low speeds, the vortices trailing from the leading edge of the double delta increase lift.

The British-French Concorde and the Russian TU-144 prototypes use a variation of the double delta wing called the ogee wing.

The evolution of the Boeing SST design was originally derived from one of the NASA designs.

Supersonic Flow

Many of the techniques used to delay transonic drag rise also are directly applicable in designing the airplane to fly with minimum wave drag in the supersonic regime.

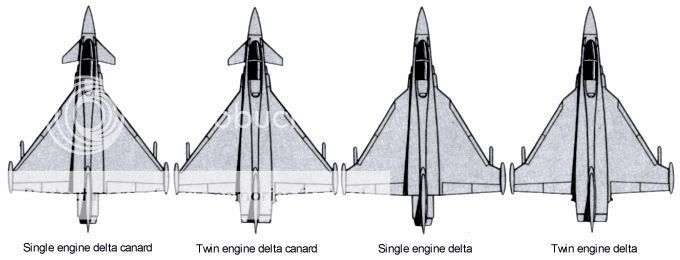

A bow shock wave will exist for free-stream Mach numbers above 1.0. In three dimensions, the bow shock is in reality a cone in shape (a Mach cone) as it extends back from the nose of the airplane. As long as the wing is swept back behind the Mach cone, there is subsonic flow over most of the wing and relatively low drag. A delta wing has the advantage of a large sweep angle but also greater wing area than a simple swept wing to compensate for the loss of lift usually experienced in sweepback. But, at still higher supersonic Mach numbers, the Mach cone may approach the leading edge of even a highly swept delta wing. This condition causes the total drag to increase rapidly and, in fact, a straight wing (no sweep) becomes preferable.

Sweepback has been used primarily in the interest of minimizing transonic and supersonic wave drag. At subsonic Mach numbers, however, the disadvantages dominate. They include high induced drag (due to small wing span or low aspect ratio), high angles of attack for maximum lift, and reduced effectiveness of trailing-edge flaps. The straight-wing airplane does not have these disadvantages. For an airplane that is designed to be multimission, for example, cruise at both subsonic and supersonic velocities, it would be advantageous to combine a straight wing and swept wing design. This is the logic for the variable sweep or swing-wing. Although not necessarily equal to the optimum configurations in their respective speed regimes, it is evident that an airplane with a swing-wing capability can, in a multimissioned role, over the total speed regime, be better than the other airplanes individually. One major drawback of the swing-wing airplane is the added weight and complexity of the sweep mechanisms. But technological advances are solving these problems also.

In addition to low-aspect-ratio wings at supersonic speeds, supersonic wave drag may also be minimized by using thin wings and area ruling. Also, long, slender, cambered fuselages minimize drag and improve the spanwise lift distribution.

The SST

On June 5, 1963, in a speech before the graduating class of the United States Air Force Academy, President John F. Kennedy committed the United States to "develop at the earliest practical date the prototype of a commercially successful supersonic transport superior to that being built in any other country in the world...." What lay ahead was years of development, competition, controversy, and ultimately rejection of the supersonic transport (SST) by the United States.

The National Aeronautics and Space Administration (NASA) did considerable work, starting in 1959, on basic configurations for the SST. There evolved four basic types of layout that were studied further by private industry. The aircraft manufacturer Lockheed chose to go with a fixed-wing delta design; whereas another aircraft company, Boeing, initially chose a swing-wing design.

One problem associated with the SST is the tendency of the nose to pitch down as it flies from subsonic to supersonic flight. The swing-wing can maintain the airplane balance and counteract the pitch-down motion. Lockheed needed to install canards (small wings placed toward the airplane nose to counteract pitch down). Eventually, the Lockheed design used a double-delta configuration and the canards were no longer needed. This design proved to have many exciting aerodynamic advantages. The forward delta begins to generate lift supersonically (negating pitch down). At low speeds the vortices trailing from the leading edge of the double delta increase lift. This means that many flaps and slats could be reduced or done away with entirely and a simpler wing design provided. In landing, the double delta experiences a ground-cushion effect that allows for lower landing speeds. This is important since three-quarters of airplane accidents occur in takeoff and landing. The British-French Concorde and the Russian Tupolev Tu-144 prototypes use a variation of the double delta wing called the ogee wing. It, too, uses the vortex-lift concept for improvement in low-speed subsonic flight.

Ultimately, Boeing with a swing-wing design was selected as the winner of the U.S. SST competition. The size of the Boeing SST design grew to meet airline payload requirements. Major design changes were incorporated into the Boeing 2707-100 design. The supersonic cruise lift-drag ratio increased from 6.75 to 8.2, and the engines were moved farther back to alleviate the exhaust impinging on the rear tail surfaces. Despite the advantages previously quoted for a swing-wing concept, technological advances in construction did not appear in time. Because of the swing-wing mechanisms and beefed-up structure due to engine placement, incurable problems in reduction of payload resulted. Boeing had no recourse but to adopt a fixed-wing concept—the B2707-300. Political, economic, and environmental factors led the United States to cancel the project in 1972.

While the British-French Concorde and Russian Tu-144 fly, research is still continuing into advanced supersonic transports in the United States. Whereas, the Concorde and Tu-144 cruise at Mach = 2.2 to 2.4, and the Boeing design cruised at Mach = 2.7, configurations with a cruise speed of Mach = 3.2 have been being analyzed.

Sonic Boom

One of the more objectionable of the problems facing any supersonic transport is commonly referred to as the "sonic boom." To explain sonic boom, one must return to a description of the shock-wave formation about an airplane flying supersonically. A typical airplane generates two main shock waves, one at the nose (bow shock) and one off the tail (tail shock). Shock waves coming off the canopy, wing leading edges, engine nacelles, etc. tend to merge with the main shocks some distance from the airplane. The resulting pressure pulse changes appear to be N-shaped. To an observer on the ground, this pulse is felt as an abrupt compression above atmospheric pressure followed by a rapid decompression below atmospheric pressure and a final recompression to atmospheric pressure. The total change takes place in one-tenth of a second or less and is felt and heard as a double jolt or boom.

The sonic boom, or the overpressures that cause them, is controlled by factors such as airplane angle of attack, altitude, cross-sectional area, Mach number, atmospheric turbulence, atmospheric conditions, and terrain. The overpressures will increase with increasing airplane angle of attack and cross-sectional area, will decrease with increasing altitude, and first increase and then decrease with increasing Mach number.

Turbulence in the atmosphere may smooth the "N" wave profile and thus lessen the impact of the boom or, on the other hand, may in fact amplify the overpressures. Reflections of the overpressures by terrain and buildings may cause multiple booms or post-boom aftershocks. In a normal atmospheric profile, the speed of sound increases with decreasing altitude. The directions in which the overpressures travel are refracted in this normal case and they will at some point curve away from the Earth. The strongest sonic boom is felt directly beneath the airplane and decreases to nothing on either side of the flight path. It is interesting to note that a turning supersonic airplane may concentrate the set of shock waves locally where they intersect the ground and produce a superboom.

Perhaps the greatest concern expressed about the sonic boom is its effect on the public. The effects run from structural damage (cracked building plaster and broken windows) down to heightened tensions and annoyance of the citizenry. For this reason, the world's airlines have been forbidden to operate supersonically over the continental United States. This necessitates, for SST operation, that supersonic flight be limited to overwater operations. Research for ways in which to reduce the sonic boom continues.

—Adapted from Talay, Theodore A. Introduction to the Aerodynamics of Flight. SP-367, Scientific and Technical Information Office, National Aeronautics and Space Administration, Washington, D.C. 1975. Available at

cover

Supersonic Flow

=============================================

Theories of Flight - An Overview

During the centuries before the Wright brothers' first flight in 1903, physical scientists had developed a large body of theory concerning fluid flow. Much of their work had focused on understanding the flow of water, and incompressible fluid, and the science of fluid flow was originally called hydrodynamics. Only a small number of these researchers were interested in studying airflow, largely because human flight was believed to be impossible. Yet because air and water are both fluids, some important concepts for the science of aerodynamics came from studies of water.

The first of these was Bernoullli's Principle, which states that in a fluid in motion, as the fluid's velocity increases, the fluid's pressure decreases. Derived by Daniel Bernoulli during the 1730s from an examination of how water flowed out of tanks, this principle is often used (not entirely correctly) to explain how wings generate lift. Because of the way wings are shaped, air flowing across the top of the wing must move faster than the air across the wing's bottom. The lower air pressure on top of the wing generates a “suction” that lifts the airplane. Bernoulli's principle was an incomplete description of how lift works, but it was a beginning.

Bernoulli's student, Leonhard Euler, made what was probably the 18th century's most important contribution to 20th century aerodynamics, the Euler equations. During a 25-year period in St. Petersberg, Russia, Euler constructed a set of equations that accurately represent both compressible and incompressible flow of any fluid, as long as one can assume that the flow is inviscid—free of the effects of viscosity. Among other things, Euler's equations allow accurate calculation of lift (but not drag). The equations were published in a set of three papers during the 1750s and were well known to individuals interested in experimenting with flying machines later in that century, such as George Cayley. Unfortunately, neither Euler nor anyone else had able to solve the equations during the 18th or early 19th centuries. This did not stop theoreticians from continuing to seek yet more powerful analytic descriptions of fluid flows. The key issue missing from Euler's description of fluid motion was the problem of friction, or what modern aerodynamicists call skin drag. During the early 19th century, two mathematicians, Frenchman Louis Navier and Englishman George Stokes, independently arrived at a set of equations that were similar to Euler's but included friction's effects. Known as the Navier-Stokes equations, these were by far the most powerful equations of fluid motion, but they were unsolvable until the mid-20th century.

The unsolvability of the highly complex Euler and Navier-Stokes equations led to two consequences. The first was that theoreticians turned to trying to simplify the equations and arrive at approximate solutions representing specific cases. This effort led to other important theoretical innovations, such as Hermann von Helmholtz's concept of vortex filaments (1858), which in turn led to Frederick Lanchester's concept of circulatory flow (1894)and to the *****-Joukowski circulation theory of lift (1906). (see fig) The second consequence was that theoretical analysis played no role in the Wright brothers' achievement of powered flight in 1903. Instead, the Wrights relied upon experimentation to figure out what theory could not yet tell them.

Experimentation with airfoil shapes had its own long history. Researchers had devised two different instruments with which to conduct airfoil experiments. The earlier device was called a whirling arm, which spun an airfoil around in a circle in order to generate lift and drag data. The second instrument, the wind tunnel, became the primary tool for aerodynamic research during the first half of the 20th century. Invented by Francis Wendham in 1870, the wind tunnel was not initially well regarded as a scientific instrument. But that changed when the Wright brothers used one of their own design to demonstrate that data produced by numerous other respected and methodical researchers using the whirling arm was wrong. The discredited whirling arm vanished as a research tool after 1903, while a vast variety of wind tunnels sprang up across the western world.

After the Wrights' success, theory and theoreticians began to play a larger role in aeronautics. One major reason why was Ludwig Prandtl, who finally explained the two most important causes of drag in 1904. Prandtl argued that the fluid immediately adjacent to a surface was motionless, and that in a thin transitional region (the boundary layer), as one moved away from the surface the fluid velocity increased rapidly. At the edge of this boundary layer, the fluid velocity reached the full, frictionless velocity that researchers had been studying for the past two centuries. Thus the effects of friction, or skin drag, were confined to the boundary layer. Under certain circumstances, this boundary layer could separate, causing a dramatic decrease in lift and increase in drag. When this happens, the airfoil has stalled. Prandtl's boundary layer theory allowed various simplifications of the Navier-Stokes equations, which in turn permitted prediction of skin friction drag and the location of flow separation for simple shapes, like cones and plates. While Prandtl's boundary layer simplifications still did not make calculation of complex shapes possible, the boundary layer theory became very important to airfoil research during the 1920s.

The 1920s also saw the beginning of research focused on what was called the compressibility problem. Because air is a compressible fluid, its behavior changes substantially at high speeds, above about 350 miles per hour (563 kilometers per hour). Airplanes could not yet go that fast, but propellers (which are also airfoils) did exceed that speed, especially at the propeller tips. Airplane designers began to notice that high-speed propellers were suffering large losses in efficiency, causing researchers to investigate. Frank Caldwell and Elisha Fales, of the U.S. Army Air Service, demonstrated in 1918 that at a critical speed (later renamed the critical Mach number) airfoils suffered dramatic increases in drag and decreases in lift. In 1926, Lyman Briggs and Hugh Dryden, in an experiment sponsored by the National Advisory Committee for Aeronautics (NACA), demonstrated that a dramatic increase in pressure occurred on the airfoil's top surface at the critical speed, indicating that the airflow was separating from the surface. Finally, the NACA's John Stack found the cause of this flow separation in 1934. Using a special camera, Stack was able to photograph the formation of shock waves above the airfoil's surface. As the figure shows, the shock wave was the termination of a pocket of supersonic flow caused by the air's acceleration over the airfoil. The shock wave, in turn, caused the boundary layer to separate, essentially stalling the airfoil.

Over the subsequent decades, several individuals found ways to delay and weaken shock wave formation to permit higher speeds. The first of these was Adolf Busemann's 1935 idea of swept wings, initially ignored but rediscovered in the 1940s by Robert T. Jones and now used on all modern jet airliners. During the 1950s, NACA researcher Richard T. Whitcomb developed the transonic area rule, which showed that one could reduce shock strength by careful tailoring of an aircraft's shape. In the 1960s, Whitcomb also demonstrated that one could design an airfoil that could operate well above the critical Mach number without encountering severe flow separation—a supercritical wing.

Supersonics

Long before Whitcomb worked out the supercritical wing, however, the quest for higher performance had led the US Air Force to demand true supersonic aircraft. From the standpoint of aerodynamic theory, supersonics posed an easier problem. On a transonic aircraft, shockwaves formed on top of the wings, meaning that part of the wing had supersonic flow and part of it had subsonic flow—a very difficult problem to resolve mathematically. In supersonic flight, however, the shockwaves formed at the aircraft's leading edges, meaning that the entire airflow around the vehicle was supersonic. This eliminated a large source of complexity. During the 19th century and the first two decades of the 20th century, researchers Leonhard Euler, G.F.B. Riemann, William Rankine, Pierre Henry Hugoniot, Ernst Mach, John William Strutt (Lord Rayleigh), Ludwig Prandtl, and Theodor Meyer had developed a solid methodology for calculating the behavior of supersonic shockwaves. During the 1920s, Swiss scientist Jakob Ackeret, working in Prandtl's laboratory at Goettingen, succeeded in simplifying, this body of theory enough so that it could be used to calculate the lift and drag of supersonic airfoils. Supersonic theory thus preceded supersonic flight substantially.

The major challenge aerodynamicists faced in making supersonic flight reasonably efficient was in finding ways to reduce the one unique kind of drag supersonic aircraft experienced: wave drag. Sonic shock waves were really compression waves, which meant that the air behind the shock was at a higher pressure than the air in front of the shock. The higher pressure behind the shock was exerted directly on the aircraft's leading edges and tended to slow it down—in other words, the higher pressure produced more pressure drag. In 1932, again well before supersonic flight was possible, Hungarian scientist Theodore von Kármán developed a method to calculate wave drag on simple bodies. It could also be used on more complex shapes, but the calculations necessary quickly became overwhelming. Through the 1960s, wave drag calculations for complex aircraft shapes were so laborious they were rarely done. Instead, aerodynamicists involved in supersonic research primarily experimented with wind tunnel models until electronic digital computers powerful enough to do the calculations became available in the 1960s.

Hypersonics

If the challenges of designing supersonic aircraft helped motivate aerodynamicists to adopt the digital computer as design tool, hypersonic vehicles sparked a new subdiscipline, aerothermodynamics. Hypersonic flight, traditionally defined as speeds above Mach 5, meant new problems for aerodynamicists, one of which was the role of heating. At high speeds, friction causes the surface of a vehicle to heat up. At Mach 6.7, the speed NASA's X-15 research aircraft reached in the early 1960s, temperatures exceed 1300° F (704° C). Vehicles returning from space hit the atmosphere at speeds above Mach 18, producing temperatures above those at the Sun's surface. This places enormous heat loads on vehicles that can destroy them if their aerodynamic characteristics are not very carefully chosen.

After World War II, as the United States began to develop rockets for use as weapons and for space flight, the need to design vehicles for heat began to supplant the need to design them for aerodynamic efficiency. The earliest, and simplest, example of how important heating is to hypersonic aircraft design was the late 1950s recognition that for vehicles re-entering the earth's atmosphere, aerodynamicists should deliberately chose aerodynamically inefficient shapes. H. Julian “Harvey” Allen of the NACA's Ames laboratory is generally credited with this realization. Engineers designing missiles in the 1940s and 1950s expected to copy the aerodynamics of artillery shells—cones flying point first—for the missiles' warheads. Allen proposed that this was exactly backward. Warheads could still be conical, but they should fly blunt-end first. Allen based his reasoning on the behavior of shock wave that formed in front of the vehicle. Shock waves dissipate energy, and the stronger the shock wave, the more energy it would dissipate away from the vehicle structure. A pointed vehicle would form a weak shockwave and therefore would experience maximum heating. A blunt vehicle would produce a much stronger shockwave, reducing the heat loading the vehicle had to withstand. In essence, Allen's blunt-body theory required aerodynamicists to discard their long-standing emphasis on aerodynamic efficiency and embrace deliberately inefficient shapes for hypersonic flight.

One unusual concept that emerged from the demands of hypersonic flight was the lifting body—an airplane without wings. In the United States, this idea was first proposed at the same 1958 NACA conference on High Speed Aerodynamics that witnessed presentation of the space capsule idea used by both the United States and Soviet Union for their space programs of the 1960s. A lifting body-based hypersonic vehicle would be shaped like a blunt half-cone, to mitigate heating, and would offer the benefit of maneuverability during landing, something the space capsule couldn't do. During the 1960s and 1970s, researchers at NASA's Dryden Flight Research Center flew a variety of lifting bodies to demonstrate the idea's feasibility, including the one prominently featured crashing at the beginning of a popular television series, The Six Million Dollar Man.

Finally, interest in hypersonic flight has led aerodynamicists to revisit the 19th century's theoretical achievements. Because the Navier-Stokes equations can handle heat-conductive air flows as well as viscous, compressible flows—at least they can if aerodynamicists can find solutions to them—they offer the hope of designing reasonably efficient hypersonic vehicles. During the late 1970s, a new subdiscipline in aerodynamics formed around the use of supercomputers to approximate solutions to the Navier-Stokes and Euler equations. Called computational fluid dynamics, or CFD, the practitioners of this discipline are turning the number-crunching power of supercomputers into a virtual wind tunnel able to fully analyze the aerodynamics of any vehicle, in any speed range.

Computational fluid dynamics is actually a very broad research program encompassing all of flight's speed ranges, from subsonic to re-entry, and because it is relatively recent, it is far from being a completed. But it promises to have its greatest impact on hypersonic flight due to the combination of inadequate test facilities and high design complexity. An example will help illustrate CFD's promise while also underscoring how far aerodynamicists have to go before hypersonic flight is well understood. During the 1980s, the US Air Force and the National Aeronautics and Space Administration ran a program to develop hypersonic vehicle that could replace the Space Shuttle, but would use air-breathing engines instead of rockets. In the early 1990s, however, it became clear that the development effort had been premature. Aerodynamicists did not know exactly how air would behave during a key part of the vehicle's flight. The CFD analysis had produced an answer, but due to the lack of test facilities no one knew whether the computer was correct. If the CFD analysis was wrong, even slightly, the vehicle would not achieve orbit. And at a cost of more than $10 billion, failure due to a lack of basic knowledge was not acceptable to anyone. Hence NASA is currently trying to verify the computer's answer by flying a CFD-designed working model, the X-43A, atop a solid-fuel booster rocket. If the X-43A performs as CFD predicts it will, then aerodynamicists will be one significant step closer to one of aviation's ultimate goals, an airplane that can reach space.

--Eric Conway

Drag

U. S. Centennial of Flight - History of Flight