THE AIRCRAFT CARRIER

MAY 20, 2014

PART 1: THE HISTORY

How the aircraft carrier idea started?

The aircraft carrier has been an idea in the minds of engineers since the early 1900’s when the dawn of the airplanes opened an entirely new way of waging war. Just the idea of being able to transport bombers over the great seas that in an instant’s notice can be launched into the air, deliver their devastating firepower to the enemies and then be safely landed again under the protection of friendly forces has been so thrilling that it has been in the center of all the world’s navies’ development departments for over a century. And in 1916, with the birth of the USS North Carolina, all engineers agreed upon that only one type of ship would be able to deliver what they all had been looking for, a whole new naval vessel – an aircraft carrier. This is the story about the birth of the carrier – from hot air balloon launches to supersonic fighters doing vertical takeoffs, an evolution starting as far back as in the end of the 19th century…

It is in the late 1800′s and the closest we get to an aircraft carrier are ships whose task is to launch hot air balloons into the air to get an overview of the battlefield. As you can imagine this was not very efficient and the engineers understood that this was an area of great improvement but they had no idea where to start – yet.

The Wright Brothers’ launching catapult

It is December 17, 1903 and the Wright brothers manage to build the first successful engine driven aircraft. To launch it they use a kind of catapult which release a heavy weight from a high tower that is connected to a wire that pulls the aircraft forward until it reaches takeoff speed. They later sold the invention to the US navy and since then the technique has been improved and refined into the vital ingredient that it today is of any fixed wing aircraft launching vessel.

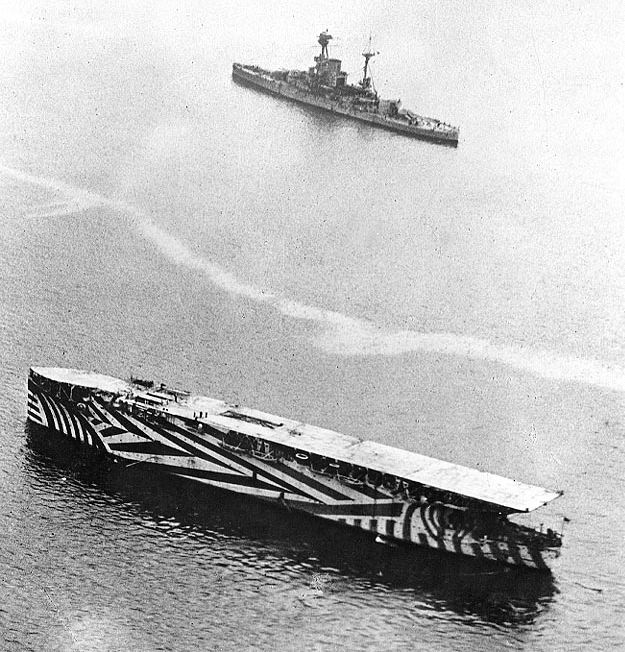

First carrier: The USS North Carolina

USS North Carolina

The next step came in 1916. The US Navy had now figured that dropping a heavy weight on a ship deck would give the ship a (very) short lifespan and instead they started thinking of other ways to rapidly release energy. The answer was compressed air. With the aid of pulleys they managed to increase the amount of energy stored in the air and after years of refining the technique they finally launched an airplane from the deck of the USS North Carolina – The aircraft carrier was born.

But the big thrill of finally being able to send torpedoes by air to destroy the enemy destroyers was soon gone because now the next problem arose – the landing. On North Carolina they used amphibious aircraft to land on the water and then lifted them up using a crane but that was not very efficient. The British Navy’s architects understood that they had to make a landing strip the length of the entire ship but there was one major problem – the superstructure (the “house” on a boat) was in the way. They first tried to split it into two parts, but the gap was not wide enough for an airplane to land so instead they started figuring on other ideas. Some of those were moving the superstructure to the left and have all the fuel to the right, or moving the storage of airplanes to the right to compensate for the weight of the superstructure. But both these ideas failed miserably, when the fuel began to decrease after days at sea the ship started to lean and the idea of moving the hangar to the right was also thrown off the drawing board once the crew started loading equipment in the former hangar-room which also this made the ship lean towards the superstructure… Finally they found the ideal solution: Have the superstructure on one side, extend the other side of the flight deck and place the heavy machinery under the extension to further balance the otherwise overwhelming weight of the superstructure – The HMS Ark Royal was born. Ever since the design was first shown in 1937 it has been used on all air craft carriers together with the tail hook which decreases the length of the required landing strip.

The extended hull mentioned is now used on all aircraft carriers. On picture: USS Enterprise

The first modern carrier – USS Midway

But such huge ships were big and easy targets as was shown in 1945 when the Japanese dropped bombs on the USS Franklin which exploded in the hangar, killing over 700 sailors. Something had to be done. Four major inventions were added to the aircraft carriers after this event: The flight deck that was earlier made out of wood was replaced with armored steel, more guns were added, it got surrounded by other naval vessels, and the use of AEWAC (radar airplanes used to look for enemies in the air) was increased dramatically. The result of all these improvements was the USS Midway, Launched in 1945.

With the dawn of the jets another problem for the carriers appeared. Previously the airplanes landing on carriers had been fixed wing propeller airplanes which moved so slow so that the pilots had well enough time to parry their aircraft into the right landing position. But the new jet fighters with touchdown speeds of over 400km/h simply did not have that time and instead needed another way to quickly get into the right angle of descend. This problem was fixed using a light that could only be seen by the pilot if he approached the aircraft carrier in the right angle – simple but genius.

USS Enterprise – the world’s first nuclear powered carrier

The last major step in the history of aircraft carriers is the refueling. A diesel driven aircraft carrier takes hours to tank, doing this during a war can be fatal for both the vessel and its crew. A new energy source had to be used. The answer was nuclear power. The first aircraft carrier built with the astonishing capability to carry the enormous reactors was the biggest one anyone had ever seen – the USS Enterprise, weighing over 90 000 tons.

Today, almost 50 years after the launch of the USS Enterprise several improvements have been made to aircraft carriers such as magnetic launch catapults, fitting the deck with heat resistant coating which makes VTOL aircraft landings possible without turning the deck into ashes, and they are fitted with more weapons and missiles than ever. But it is still the greatest ideas from the best naval and aircraft engineers from all over the world, from the beginning of the 20th century to today, who has made the creation of the biggest and most modern aircraft carrier ever built possible - the USS Nimitz.

PART 2: THE EXTERIOR

The aircraft carrier is widely known to be a weapon of tremendous power but its shape and size looks like nothing else and its features are surprisingly unknown to ordinary people. That is the reason why in this article we will look into the exterior of this devastating vessel. The aircraft carrier which will be focused on is the USS Nimitz, the world’s biggest carrier, weighing over 100,000 tons. Some of the questions that we will try to answer are:

- Why does an Aircraft Carrier look like it does?

- How are the aircraft launched from an Aircraft Carrier?

- How effective are an Aircraft Carrier’s weapons?

The design of the USS Nimitz’s hull

USS Nimitz (model) from above

If we start with the looks of it those are derived from mainly three things: The size of the flight deck, the weight distribution of the boat and water resistance minimization. If we look at the USS Nimitz from above we see that a small part on one of the sides is made up by the “tower”, called the superstructure. It has been placed on one side of the ship to make place for the incoming aircraft and so improving the area of the landing strip. The fact that it has been placed on the edge makes the open surface even bigger because to balance the weight from the superstructure the flight deck on the other side is extended and so makes the deck even bigger. The reason for aircraft carriers not to be built like enormous squares is because the water resistance would be overwhelming and the engines would not be able to propel the carrier very fast with that design. That is why the vessel is so long and also why the hull is so pointed under the front part of the launch strip. It is simply to split the water in half and so minimizing the resistance that the water makes on the aircraft carrier’s movement.

The flight deck of a top modern carrier

EMALS being installed

The surface of the USS Nimitz has so many technological features that they can not all be written down here but I will mention the most important things of the deck. The catapults of an aircraft carrier are used to limit the takeoff length of a jet fighter from over a kilometer to a mere 100 meters. They work as such that the aircraft’s landing gear connects to a hook in the surface. When the pilot waves to the control tower that he is ready, hot pressurized steam is led into two pipes that ends in the hook that the jet is connected to in the deck and shoots forward, assisting the airplane with its takeoff. But as technology advances so do aircraft carriers. In the new USS Gerald R Ford class, the steam catapults have been replaced with electromagnetic ones, called EMALS (electromagnetic aircraft launch system). The advantage of those are that they deliver higher energy, need less maintenance and occupy less space under the surface of the deck. Another feature of the deck on the USS Nimitz is the coating of it. The coating on the surface is constructed so that it is anti-slip, preventing the aircraft to slide during heavy seas and landings, and also heat resistant which makes it possible for STOVL (Short Take Off Vertical Landing) jets such as the Lockheed Martin F-35 Lightning II to land vertically. If the carrier would not have this feature the F-35’s down-facing nozzle would melt the carrier’s surface. A small feature which really helps the crew of the carrier are all the white lines that indicates where airplanes can be launched, where airplanes can be put without being in the way of others, and where the steam catapults are hidden.

The well defended air base – USS Nimitz

SLQ-32 Electronic warfare suite antenna

The weapons and sensors of the USS Nimitz is an artwork in itself. The ship has enough weapons to defend both the vessel as well as its crew from anything that the enemy might send to sink it. First of all if the enemy would send a missile to sink a modern carrier the carrier sees this with its advanced SLQ-32A electronic warfare suite and AEWACs long before impact. It then launches its interceptors, usually F-18’s to take out the threat. If that against all odds would fail an aircraft carrier worth $4.5 billion is never on its own. It is constantly being guarded by destroyers that would shoot down the intruders as soon as they are within range. Lastly the Nimitz has defenses on its own consisting of Nixie torpedo countermeasures, three 20 mm Phalanx turrets and sea-skimming missiles built to take out incoming anti-ship missiles. There are almost no offensive weapons on an aircraft carrier as its offensive strength lies in its aircraft. However the USS Nimitz has been fitted with two sea sparrow launch tubes, two RIM-116 Rolling Frame Missile launchers and the three previously mentioned 20 mm Phalanx turrets.

To conclude this part of the series it is needed to be said that carriers can have a huge impact. With some aircraft carriers’ capabilities of carrying over 90 aircraft to a war zone, its presence could mean the difference between winning or loosing. Its incredible firepower of both jets and missiles combined with top modern sensors makes it an effective weapon. Its catapults can launch one fighter every 20 seconds, so it can have an air fleet bigger than a small country’s up in the air in less than 30 minutes. This is what makes Nimitz class aircraft carriers and the lead ship of its class, the USS Nimitz, one of the greatest and most devastating naval vessels ever built.

PART 3: THE INTERIOR

The Nimitz aircraft carrier. An enormous source of destruction, capable of delivering hundreds of tons of explosives to its enemy in under a hour, but it’s much more than that. Its 100 000 tons of steel, 18 floors under deck and its impressive length of 332 meters is much more than just weapons. It is a floating city. In this part of the article series about aircraft carriers the focus will be on its interior covering electronic systems, the crew, engines and hangar – everything that makes this impressive machine work and maintain its efficiency during its 50 years lifespan.

The crew’s part of the USS Nimitz

Diagram showing all parts of the Nimitz

The crew of a 100 000 ton ship is tremendous. Did you know that the crew consists of 3200 people – not counting the additional 2500 air wing men (pilots, mechanics and other aircraft related jobs) – when the Nimitz class carriers is out at sea? The logement is located in the bow of the vessel, right under the main launch strip. Here the crew has access to their own bedroom which is usually shared with 5 others, kitchen, enormous diner halls, doctors, a telephone bank to call their family, barber shops, chapels, an aviation jet engine workshop/maintenance facility, athletic facilities such as a gym and even a dentist’s office. But even though the ship has all of these installations it is also very tough for the crew. They are not allowed to hang around on the deck and since the size of the island (the superstructure) is so limited the members of the crew can’t spend their time their either. This means for some of the crew members that work deep within the carrier it can go weeks without them seeing any daylight.

Below the surface of an aircraft carrier

One of the three hangars of the USS Nimitz

Under the deck many things are going on. There is the engine room and an elevator which transports the aircraft down below the deck into the enormous hangar. Under the deck are also almost all of the control rooms located. Since the “island” is made as small as possible the only workstations in the superstructure are the bridge, chart room, radar-and-surveillance systems and the flight deck control room. All the others of the total 6000 people on the vessel are working below the deck. For instance the Catapult Piping Launch Room which’s task is to assist the aircraft with its launch is located right under the takeoff strip. The room which tunes and controls the catapults are located under the hangar in the center of the vessel so that they are protected from potential incoming fire.

The energy source of CVNs

Nuclear reactors of the USS Nimitz class

The engines and energy source of the USS Nimitz and other modern carriers are made up of nuclear reactors which heat water that drives turbines, propelling the vessel forward. When the turbines run on full power they are capable of making the 100 000 ton heavy aircraft carrier move at speeds as high as 58 km/h. The energy harvested form the A4W reactors is also used to drive the thousands of computers and other electronic equipment on board. Some of the electrical energy requiring systems with the highest consumption on board any modern day carrier include: air search radars, target acquisition radar, air traffic control radars, landing aid radar and the NSSM guidance systems. But of course the energy is also used for smaller but still vital systems such as pumping drinking water, lifting airplanes in the hangar, cleaning and circulating the air and refrigerators and ovens for the crew’s food.

In the stern of the boat, behind the hangar and above the rear phalanx turrets, the squadron ready rooms and the ship’s small boats are located. These boats are used by the crew to for instance get to the other vessels of the battle group (destroyers, submarines and cruisers supporting the carrier) and to get to shore to deliver mail that is then sent home to the US. All aircraft carriers of the US Navy are regarded as sovereign US territory even though they are on international water, that is why they all operate under their own ZIP-code.

The Nimitz aircraft carriers are the biggest ever built and they possess a tremendous firepower. But the destruction of which they are capable of is relying on the crew and the subsystems keeping this complex system working – a chain is never stronger than its weakest link. Over 100 years of innovation has lead up the perfection achieved today – the 10 USS Nimitz class aircraft carriers are the undisputed heroes of the seas. With 18 floors under deck, 332 meters long, 77 meters high, 90 aircraft, 100 000 tons of pure steel and a complement of over 3200 sailors and close to 6000 crew total, this is truly the world’s biggest vessel – ever built.

source:

The history about the biggest naval vessels – Aircraft carriers » MiGFlug.com Blog